Prefabricated Concrete Floorboard Making Machine

- Loading Port:

- Qingdao

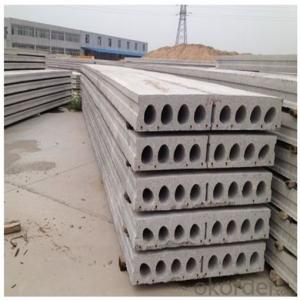

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefabricated Concrete Floorboard Making Machine

1. Structure of Prefabricated Concrete Floorboard Making Machine:

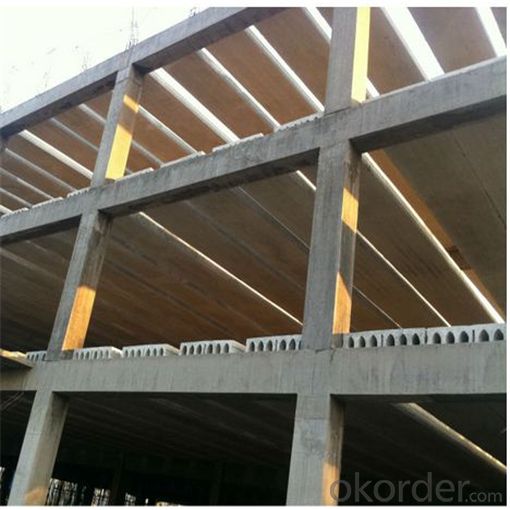

Products of this series (non-circular and circular cored) are the ideal machines for making building materials on constructions of large span and heavy load bearing in factories, schools, hospitals, shopping centers, office building and homes.

Our hollow core slab machines have the advantages of reasonable design, easy operation, convenient maintenance and long working life. Slab length can be achieved to 4.2m to 18m; width of 600mm, 900mm and 1200mm; thickness of 120mm, 150mm, 180mm, 200mm, 250mm, 300mm, 380mm.

The hollow core slab machines are working on the long-line table, tensioning the high-strength and low-relaxation steel strand first, and using the pushing work method to form the concrete hollow core slab. The slabs which being formed have the advantages of smooth surface and high-density structure.

2. Main Features of Prefabricated Concrete Floorboard Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Prefabricated Concrete Floorboard Making Machine Images:

4. Prefabricated Concrete Floorboard Making Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q:Where can I sell used printing machinery and equipment online?

- OKorder

- Q:How come Chinese people make farming machinery whereas black African people do not and thus have famines?

- cos it costs to make farming machinary

- Q:I need it!!

- try okorder /

- Q:A. physicalB. intangibleC. tangibleD. transient

- i guess c

- Q:Any manufacturers or suppliers give the details of above matter in India

- Here's okorder /

- Q:Do engineering technicians get to invent and patent ideas within large companies, or is this typically reserved for the mechanical engineers?

- Mostly, engineer's are problem solver's. In the case of mechanical engineers. you are partly correct. They are given a problem, like they need a machine that can build a part or perform some action, but has to fit within certin peramiters. So the engineer has to figure out how to make it work. But this is only a small part of what an engineer does.

- Q:On October 1, 2007, Machinery B was acquired with a down payment of $5,740 and the remainingpayments to be made in 11 annual installments of $6,000 each beginning October 1, 2007. Theprevailing interest rate was 8%. The following data were abstracted from present-value tables(rounded).Present value of $1.00 at 8% Present value of an ordinary annuity of $1.00 at 8%10 years .463 10 years 6.71011 years .429 11 years 7.13915 years .315 15 years 8.559

- $6,000 X 11 + $5,740

- Q:what does machinery safety engineer do?

- Basically, they inspect every machinery and make sure that it is perfectly functional and that all safety standards are met. Safety engineers are also involved in the planning and consultation in the event that a machine is required to be moved or relocated. Safety engineers plays a major role in a machinery relocation firm such as the www.hanlonandwright .uk/.

- Q:I have to gain my wishes..People, somebody tell me. we were born, grew up, made choices (still making) and then society wants us to reproduce. Must everything be machinery?

- If you seek the reasons for being to start with, society today is just a bad play. Look toward more natural reasons for being, that is, think upon the meditative and forget the calculative that is our world. Just shut it out for a little while and get back to basics. Look for something beautiful in every day. If we could see the miracle of a single flower clearly, our whole life would change. --Buddha

- Q:would you be able to give reasons

- the general consensus is that the type of financing should match the lifespan of whatever you're buying. so for heavy machinery, these are typically long-term assets. as such, you want to use long-term debt (such as a long-term bank loan). ideally, the best financing is cash (you buy it outright). other alternatives would be to give the seller a corporate bond which promises them payments, etc. loan agreements are another option.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prefabricated Concrete Floorboard Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords