Auto Polishing Peeling and Grinding CNC Machine JN-T8/D8/D10 for Prouding Faucets

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

We are supplying new generation CNC peeling machine which is high-precision, high-efficiency and energy-saving. It has a great improvement on the traditional grinding process.

The machine adopts gantry type body and it covers an area of only 8m², can process 8 faucets at a time, and the brass recovery rate is 100%.The casting bodies can be processed directly on this machine after the excess parts are cut off.This machine can remove all draft surfaces on products. Finish the surface up to 220-240 mesh which can replace the rough grinding process.

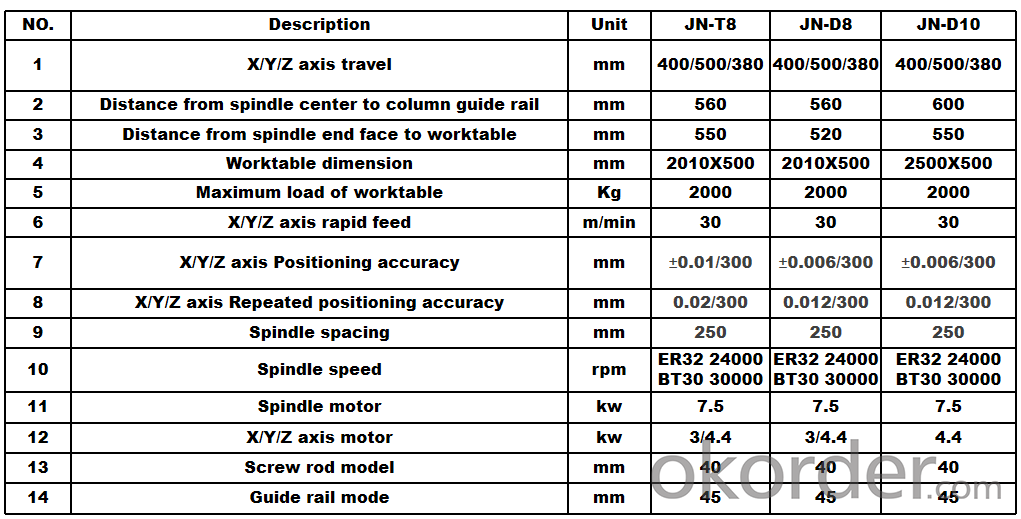

Model:JN-T8、JN-D8、JN-D10

System option:Siemens、Mitsubishi、Syntec

Technical Parameter

Package

Global Sales Market

International Partner

Q&A

Q1. Where is your factory located?

A : Our factory is located in Taizhou City, Zhejiang Province, China.

Q2. Are you produce peeling/ polishing machine's specific parameters according to the samples?

A: Yes, we produce the machine you want by your samples or technical drawings.

Q3. What is your sample service?

A: We can supply the sample testing which client want to produce if we have ready machine in stock.

Q4. What is your MOQ of your machine?

A: Normally our MOQ is 1 set.

Q5. Do you test all your machine before delivery?

A: Yes, we have 100% test before delivery.

Q6: What is the payment term?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q7: What is the normal lead time?

A: 45-60 days after we receive the deposit.

Q8: Guarantee Period?

A: 1 year. During the guarantee period, we guarantee to solve all problems may occur due to machine's quality or wrong design, and to provide all necessary spare parts for repair. We can send the technician to customer's factory if problem is serious and can't be solved by the customer.

- Q:How to set up the CNC vertical machining center

- Round the workpiece, to see what to process, and if the surface processing without the angle of the painting can not be found.

- Q:Machining center z axis tooling

- And then in the relative coordinates of Z to zero. Behind the second to the third ... ... and so on, are in accordance with the length of the first tool to compensate ,,, the second tool to start with G43 H - how much

- Q:What are the advantages of woodworking centers?

- And the use of CNC machine tools, it is necessary to pre-operation of various operations and machine movements, according to the provisions of the digital form of programming procedures recorded in the control medium, to achieve human and machine contact.

- Q:Processing center models are what? How to classify the various models are on behalf of what does this mean?

- Processing center discrete and lying plus, gantry machining center, CNC boring and milling machining center

- Q:How is the center of the processing center?

- Use the edge finder to install the edge device and then MDI mode input S500M3; sure to confirm the speed and then start there will be life-threatening if more than 0 input S5000 did not pay attention to the edge of the edge of the direct rejection of the consequences are very serious!

- Q:Which big god gets advice, cnc processing center g code g28g98g99 in the end what is the meaning. To be detailed. Have labor Thank you

- 91G30Z0 (Z axis back to the library 0 zero, the height of the knife, the point of some machines and machinery 0 points coincide)

- Q:What does metal processing machinery include?

- ; Metal cutting machine: drilling, reaming, metal cutting, cutting tools, trimming, gear cutting, etc .; surface treatment / forming: molding machinery, planing, painting systems and other materials handling: cranes, transmission systems, lifts,

- Q:Five-sided machining center and five-axis machining center What is the difference

- Mostly refers to the gantry machining center. Only use a composite milling head

- Q:Will the CNC machining center and computer gong What is the difference

- Compared with ordinary machine tools, CNC machine tools have the following characteristics:

- Q:What is the precision machining center?

- Ultra-precision machining technology, office and production workshop, said the precision, ultra-precision machining technology is to improve the performance of mechanical and electrical products, quality, working life and reliability, as well as an important way to save energy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Auto Polishing Peeling and Grinding CNC Machine JN-T8/D8/D10 for Prouding Faucets

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches