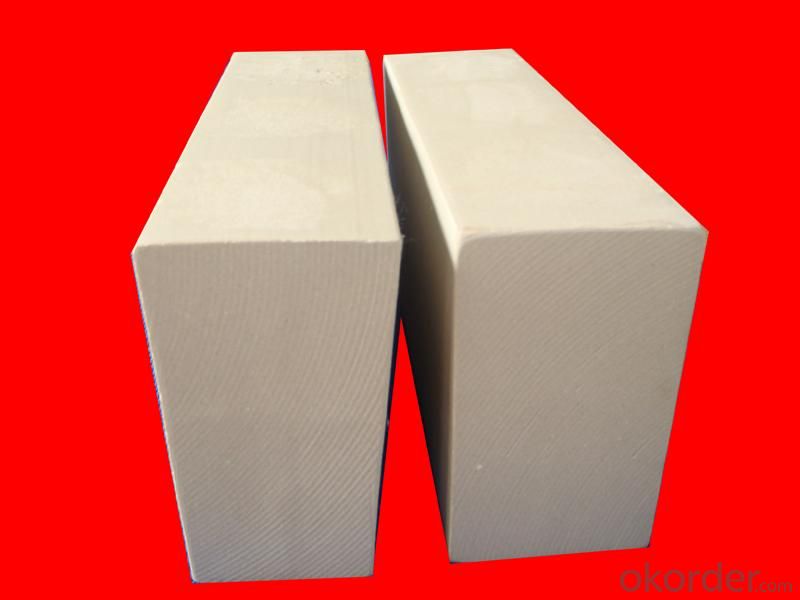

Refractory Brick with Quick Response Refractory Fire Brick for Aluminum Refinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

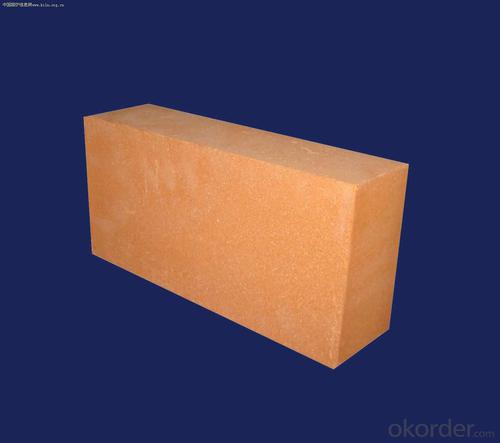

The product is made from high quality Silicon carbide, silica powder, metal Si,by vacuum Nitride Sintering at high temperature.

The size&properties of the product can be customized as per your application,&special technical requirement.

Generally,the product has following advantages of:

1.Low thermal conductivity

2.Low thermal expansion

3.Excellent oxidation resistance

4.Excellent corrosion resistance

5.long duration

Application:

1.good lining refractory materials in Aluminum electrolysis cell,furnace,kiln,incinerators, and reactors.

2.as Tuyere combined bricks or other combined blocks in Iron&steel industry.

3.Used as Kiln shed board, beams,slide push board, sagger.

Package:Normally,1000kg or1100kg into a pallet,each piece is isolated by good padpaper,bubble film,or foam board,etc..Outside,with tight shrink film wrapping around and anti collision bars&big fiber board in sides.

The customized package is available.

Parameter:

item | unit | data |

SiC% | ≥ | 72 |

Si3N4 % | ≥ | 21 |

Fe2O3 % | ≤ | 0.5 |

Density | g/cm3 | 2.65-2.70 |

Apparent porosity % | ≤ | 18 |

Modulus of Rupture | Mpa (at ambient temperature) | 42 |

Mpa(1400°C) | 45 | |

Compressive strength | MPA≥ | 150 |

thermal conductivity1250°C | W/m.k | 15-18 |

acid-proof alkaline | Excellent | |

Size Difference | 0-100mm | ±1.0 |

101-300mm | ±1.5 | |

301-500mm | ±2.0 | |

501mm above | ±0.5% |

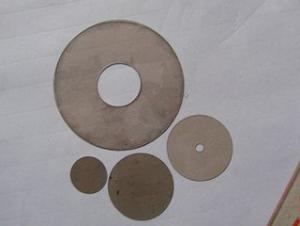

Product2: Composite Sidewall Slab for Aluminum Reduction Cell (side wall block,combo brick)

Description

With special bonding developed by us,stick graphitic carbon pieces with SiC brick tightly.Can be used directly at Aluminum reduction cells.

The feature:excellent chemical&oxidation resistance,Longer duration,convenient for installation.and so on.

Specification:610mm*400mm*75/210mm,or other sizes as per your requirement.

- Q:Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q:What role does dolomite play in rock wool products?

- Polyurethane is a field foam molding, process equipment is simple, easy to operate, you can spray can also be poured, in any complex roof construction operations

- Q:Rock wool board is inorganic composite insulation material

- Rock wool products are inorganic insulation materials

- Q:Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q:The difference between rock wool and rock wool

- The difference between rock wool and rock wool

- Q:What does the rock wool board look like?

- June 1981 test success Rock wool board is a new type of insulation, fire, sound absorption material.

- Q:How to judge the quality of rock wool

- Appearance and quality: Choose the material surface smooth and beautiful, no stains, no damage to the material

- Q:Rock wool insulation material fire rating is how much

- Yanmian, mineral wool and its products are slag and basalt and other natural ore as the main raw material, the high temperature melt fiber, adding the right amount of adhesive processing

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refractory Brick with Quick Response Refractory Fire Brick for Aluminum Refinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords