Prime Quality Q195/215 CNBM Steel Billets with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

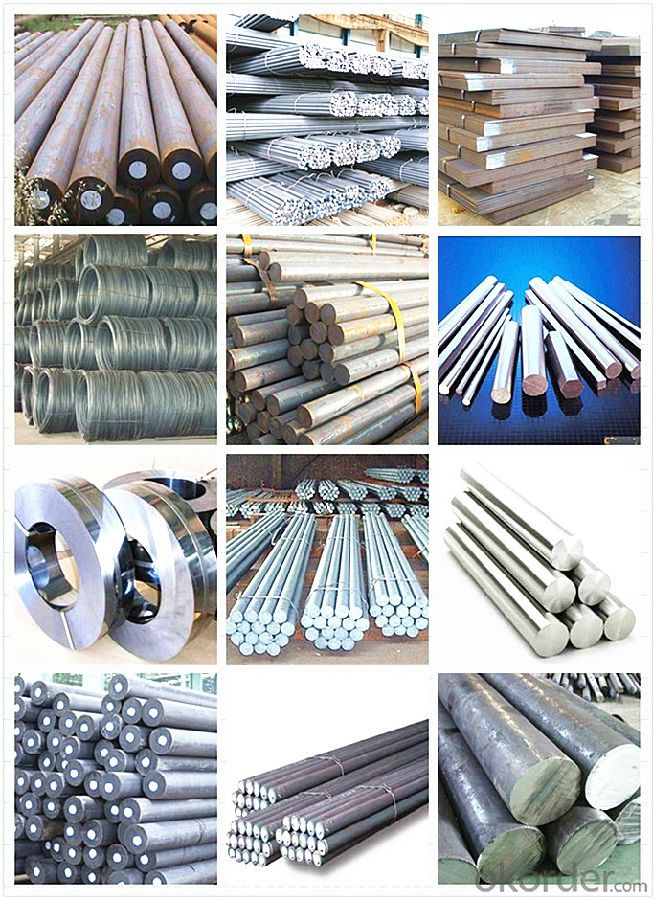

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:How does special steel contribute to the medical industry?

- Special steel contributes to the medical industry by providing the necessary materials for the production of medical equipment and devices. Its unique properties such as high strength, corrosion resistance, and biocompatibility make it ideal for manufacturing surgical instruments, implants, and prosthetics. Special steel also ensures the safety and effectiveness of medical tools, as it can withstand sterilization processes and maintain its integrity during procedures. Overall, special steel plays a crucial role in advancing medical technology and improving patient care.

- Q:What are the common challenges in welding special steel?

- When welding special steel, there are several challenges that differ from welding regular carbon steel. Some common challenges in welding special steel include the following: 1. High carbon content: Special steels often have a high carbon content, which can increase hardness and brittleness. Achieving a proper weld without cracks or defects can be more difficult. 2. High alloy content: Special steels often contain various alloying elements like chromium, nickel, or molybdenum, which can affect weldability. These elements can introduce complexities, such as increased susceptibility to heat-affected zone (HAZ) cracking or the formation of brittle phases. 3. Heat sensitivity: Special steels are often more sensitive to heat during welding. Excessive heat can cause grain growth, reduced mechanical properties, or distortion of the welded structure. Therefore, careful control of heat input and preheating techniques may be necessary. 4. Pre-weld and post-weld treatments: Specific pre-weld and post-weld treatments may be required for special steels to ensure proper weld quality and performance. These treatments can include preheating, stress relieving, or post-weld heat treatment. Failure to follow these procedures can result in residual stresses or reduced mechanical properties. 5. Joint design and fit-up: The design and fit-up of the weld joint can also present challenges. Special steels may require specific joint configurations, such as a double-V or double-U groove, to ensure adequate penetration and fusion. Additionally, tight tolerances may be necessary to maintain desired mechanical properties. 6. Welding process selection: The choice of welding process can greatly impact the success of welding special steel. TIG or laser welding may be more suitable for high-alloy steels, while MIG or submerged arc welding may be better for specific applications. Selecting the appropriate welding process is crucial for achieving a sound weld with desired properties. To overcome these challenges, it is essential to thoroughly understand the specific type of special steel being welded and follow proper welding procedures and techniques. This may involve conducting pre-weld qualification tests, using suitable welding consumables, and ensuring proper heat control throughout the welding process. Additionally, working with experienced welders and seeking guidance from experts in special steel welding can effectively overcome these challenges.

- Q:What are the main challenges in machining special steel?

- The main challenges in machining special steel include its high hardness and low machinability, which make it difficult to cut and shape. Special steels also have a tendency to work harden, causing tools to wear out quickly. Additionally, special steels often contain alloying elements that can lead to heat build-up during machining, requiring careful selection of cutting parameters and cooling methods.

- Q:How is wear-resistant steel used in mining and earthmoving equipment?

- Wear-resistant steel is extensively used in mining and earthmoving equipment due to its exceptional properties that enable it to withstand harsh conditions. It is used to manufacture various components, such as buckets, blades, crushers, and drilling equipment, which are subjected to intense abrasion and impact. The wear-resistant steel's hardness, durability, and resistance to wear and tear make it ideal for protecting these equipment parts from excessive damage and extending their lifespan.

- Q:What are the different methods of preventing stress corrosion cracking in special steel?

- There are several methods to prevent stress corrosion cracking in special steel. One common approach is to select a steel alloy with enhanced resistance to stress corrosion cracking. This can be achieved by adding alloying elements such as nickel, chromium, or molybdenum, which help improve the steel's corrosion resistance. Another method is to control the environment in which the steel is exposed. This can involve minimizing exposure to corrosive substances or adjusting temperature and humidity levels. Additionally, surface treatments such as passivation or coating can be applied to create a protective barrier against corrosion. Regular inspection and maintenance of the steel structure are also important to identify and address any potential sources of stress corrosion cracking.

- Q:How is corrosion-resistant stainless tool steel used in the production of food processing equipment?

- Corrosion-resistant stainless tool steel is used in the production of food processing equipment because it offers a high level of resistance against chemical reactions, rust, and staining caused by exposure to moisture and food acids. This type of steel helps ensure that the equipment remains durable, hygienic, and safe for food processing operations.

- Q:How is special steel used in the aerospace manufacturing process?

- Special steel is used in the aerospace manufacturing process primarily for its strength, durability, and resistance to extreme temperature and pressure conditions. It is commonly employed in the construction of critical components such as turbine blades, landing gear, and structural parts of aircraft. The unique properties of special steel enable it to withstand the demanding environments and ensure the safety and reliability of aerospace systems.

- Q:What are the different methods for improving the heat resistance of special steel?

- There are several methods for improving the heat resistance of special steel. These methods include: 1. Alloying: One of the most common methods is to alloy the steel with certain elements that enhance its heat resistance. For example, the addition of chromium, nickel, or molybdenum can significantly improve the steel's ability to withstand high temperatures. 2. Heat treatment: Heat treatment processes such as annealing, quenching, and tempering can be employed to enhance the heat resistance of special steel. These processes help in refining the microstructure of the steel and improving its mechanical properties, including heat resistance. 3. Surface modification: Applying specialized coatings or surface treatments can also improve the heat resistance of special steel. For instance, processes like nitriding, carburizing, or ceramic coating can create a protective layer on the surface of the steel, preventing oxidation and improving its ability to withstand high temperatures. 4. Grain refinement: Controlling the grain size of the steel through processes like grain refinement or recrystallization can enhance its heat resistance. Smaller grain sizes reduce the diffusion of atoms within the material, making it more resistant to high temperatures. 5. Precipitation hardening: Precipitation hardening is a technique where small particles are formed within the steel matrix, strengthening the material and improving its resistance to heat. This method involves a specific heat treatment process that enables the formation of these particles. 6. Controlled cooling: Optimizing the cooling process after heat treatment can also improve the heat resistance of special steel. By controlling the cooling rate, the formation of undesirable phases or microstructural defects can be minimized, ensuring better heat resistance. 7. Material selection: Choosing the right type of special steel with inherently high heat resistance properties is another method for improving heat resistance. For example, stainless steel, tool steel, or superalloys are known for their excellent heat resistance and are often selected for applications where high temperatures are involved. It is worth noting that the selection of the appropriate method or combination of methods for improving heat resistance depends on the specific requirements and constraints of the application.

- Q:What are the characteristics of special stainless steel?

- Special stainless steel, also known as superalloys, possess several unique characteristics. Firstly, they exhibit exceptional resistance to corrosion, making them highly durable and long-lasting in harsh environments. Additionally, they have high strength and toughness, allowing them to withstand extreme temperatures and pressures. Special stainless steel also demonstrates excellent heat resistance, making it suitable for applications in high-temperature environments. Furthermore, these alloys often exhibit superior chemical stability, resistance to wear and tear, and excellent mechanical properties, making them highly versatile for various industrial applications.

- Q:How is special steel stored and transported?

- Special steel is typically stored and transported in a controlled environment to ensure its quality and prevent any damage or contamination. It is stored in covered warehouses or facilities equipped with proper ventilation, humidity control, and temperature regulation. Additionally, special steel is often stored on racks or shelves to prevent direct contact with the ground and minimize the risk of corrosion. When it comes to transportation, special steel is usually transported in specially designed containers or crates, ensuring protection from external elements and providing secure handling during transit.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Quality Q195/215 CNBM Steel Billets with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords