Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request.

2. Length: 6m, 9m, 12m.

3. Sizes:

Size(mm) | Mass(Kg/m) | Size(mm) | Mass(Kg/m) |

50*50*4 | 3.059 | 63*63*5 | 4.822 |

50*50*5 | 3.77 | 63*63*6 | 5.721 |

50*50*6 | 4.465 | | |

Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C.

Packaging & Delivery of Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

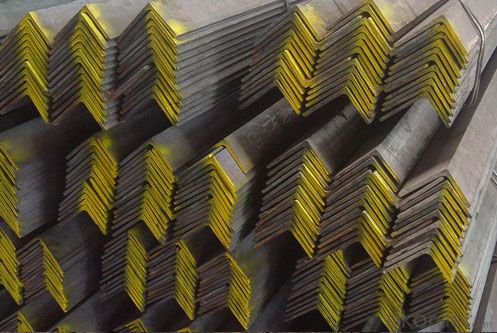

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

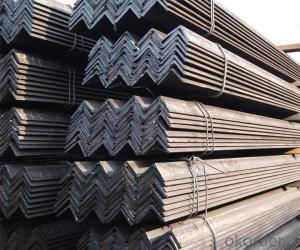

Images:

- Q:Can steel angles be used for fencing?

- Yes, steel angles can be used for fencing. Steel angles are commonly used in fencing applications due to their strength, durability, and versatility. They provide a sturdy framework for the fence, ensuring stability and security. Steel angles can be easily installed, and their design allows for different fence styles and heights. Additionally, they are resistant to rust and corrosion, making them suitable for outdoor use. Overall, steel angles are a popular choice for fencing projects due to their structural integrity and long-lasting performance.

- Q:Can steel angles be used for framing in modular homes?

- Absolutely! Framing in modular homes can indeed make use of steel angles. In construction, steel angles are widely employed due to their robustness and long-lasting nature. Their versatility enables them to be utilized in a multitude of applications, including framing. Steel angles possess exceptional load-bearing capabilities and offer remarkable structural support, which renders them ideal for modular home construction. Moreover, they can effortlessly be fabricated and tailored to meet precise design specifications. Their resistance to corrosion and fire further enhances their appropriateness for framing in modular homes. All in all, steel angles emerge as a dependable and effective option for framing in modular homes.

- Q:Can steel angles be used for manufacturing window frames?

- Indeed, the utilization of steel angles is feasible for the production of window frames. Given their robustness, longevity, and versatility, steel angles are extensively employed in both construction and manufacturing. They furnish a robust structure for windows, capable of enduring the weight and force exerted by the window glass. The assembly of steel angles through welding, bolting, or screwing allows for the creation of a robust and steady window frame. Furthermore, steel angles can be tailored to meet precise design specifications, rendering them suitable for a wide array of window sizes and shapes. All in all, owing to their dependability, strength, and adaptability, steel angles are a favored option for the manufacturing of window frames.

- Q:Can steel angles be used in earthquake-resistant construction?

- Indeed, earthquake-resistant construction can incorporate steel angles. Due to their exceptional strength and durability, steel angles are frequently employed as structural elements in buildings. In earthquake-resistant construction, steel angles serve the purpose of offering supplementary bracing and reinforcement to the structural system of the building. Through strategic placement, such as at the corners or edges, steel angles aid in the more efficient distribution of earthquake forces and mitigate the risk of structural failure. Moreover, steel angles can be utilized to construct moment-resisting frames or as part of a steel moment frame system, which is highly effective in withstanding lateral forces during an earthquake. In summary, steel angles play a vital role in enhancing a building's seismic performance and are a valuable asset in earthquake-resistant construction.

- Q:What is the typical thickness of a steel angle?

- The typical thickness of a steel angle can vary depending on the specific application and size of the angle. However, common thicknesses range from 1/8 inch to 3/8 inch.

- Q:What is a steel angle?

- An angle iron, also called a steel angle or L-shaped bar, is a type of structural steel product. It consists of two legs that are joined together at a 90-degree angle. This product is widely used in the fields of construction and engineering to provide support and reinforcement to various structures. Its strength and versatility make it a preferred choice in these applications. Steel angles can be made from either carbon steel or stainless steel. They are available in different dimensions, thicknesses, and lengths to cater to different project needs. These angles can be easily cut, welded, and bolted, making them highly convenient for framing, bracing, and supporting beams, columns, and other structural components. In addition to their use in construction and engineering, steel angles are frequently employed in the manufacturing of shelves, brackets, frames, and other metalwork applications.

- Q:How do you determine the appropriate thickness of a steel angle for a specific application?

- To determine the appropriate thickness of a steel angle for a specific application, several factors need to be considered. Firstly, it is important to understand the load or weight that will be applied to the steel angle. This includes both the static load, which is the weight that the angle will bear continuously, and the dynamic load, which is any additional force that may be applied intermittently. The magnitude of the load will determine the strength requirements of the steel angle. Secondly, the length of the steel angle needs to be taken into account. Longer angles will experience greater deflection and bending, so a thicker angle may be required to provide sufficient rigidity and prevent deformation under the load. Another crucial factor to consider is the type of steel being used. Different grades of steel have varying strength properties, and the appropriate thickness will depend on the specific grade. It is important to consult the material specifications and standards to ensure the chosen steel angle meets the required strength and durability criteria for the application. Furthermore, the support conditions and the method of attachment should be considered. The way the steel angle is connected to other structural elements will affect its load-bearing capacity. If the angle is bolted or welded to other components, its thickness must be chosen to suit the specific connection method and account for any additional stresses induced by the attachment process. Lastly, any applicable industry standards, codes, or regulations should be followed when determining the appropriate thickness of a steel angle. These standards often provide guidelines or calculations for selecting the correct size and thickness based on the intended application, load, and other design factors. In summary, determining the appropriate thickness of a steel angle for a specific application requires considering factors such as the load magnitude, length, steel grade, support conditions, and attachment method. Consulting material specifications, industry standards, and seeking professional advice can help ensure the chosen steel angle meets the required strength and durability requirements.

- Q:Can steel angles be used for stairs?

- Stairs can indeed utilize steel angles. The construction industry frequently employs steel angles for a multitude of purposes, including the creation of staircases. These angles are frequently employed to provide the necessary structural support for stair treads and risers. By incorporating steel angles, stairs gain durability and stability, rendering them a favored option for both residential and commercial structures. Moreover, steel angles boast adaptability for stair construction as they can be effortlessly tailored and fabricated to meet unique design specifications.

- Q:What are the different methods of cutting steel angles?

- There are various techniques employed for cutting steel angles, depending on the specific needs and resources at hand. Some commonly utilized methods are as follows: 1. Circular or bandsaw cutting: This approach entails using a circular saw or bandsaw equipped with a metal cutting blade. It ensures a clean and precise cut, particularly for smaller angles. 2. Laser cutting: For intricate designs and complex shapes, laser cutting proves highly accurate and efficient. It employs a concentrated laser beam to melt or vaporize the steel angle. 3. Plasma cutting: When dealing with thicker steel angles, plasma cutting is a versatile method that employs a high-temperature plasma arc to melt the metal and eliminate the molten material. 4. Waterjet cutting: This technique involves employing a high-pressure water jet mixed with abrasive particles to erode the steel angle. It is excellent for cutting thick angles and creating intricate patterns. 5. Shearing: For straight cuts, shearing involves using a machine fitted with a sharp blade to slice through the steel angle. It is suitable for thinner angles. 6. Abrasive cutting: By employing a rotary wheel embedded with abrasive particles, abrasive cutting can cut through the steel angle relatively quickly and cost-effectively. However, it may result in a rougher surface. 7. Flame cutting: Flame cutting, also known as oxy-fuel cutting, employs a mixture of fuel gas and oxygen to create a high-temperature flame that melts the steel angle. It is suitable for cutting thicker angles but may result in a heat-affected zone. Each cutting method possesses its own advantages and limitations. The choice of method depends on factors such as the angle's thickness, complexity of the cut, desired precision, and available equipment. Safety precautions must be considered, and the most appropriate method should be selected to ensure a successful and efficient steel angle cutting process.

- Q:Can steel angles be used in automotive applications?

- Indeed, automotive applications can make use of steel angles. The automotive industry frequently employs steel angles for a multitude of purposes, including frames, chassis, supports, brackets, and reinforcements. The reason behind this preference lies in the fact that steel angles possess exceptional strength, durability, and resistance to impact and vibrations. Consequently, they prove suitable for enduring the challenging conditions and demanding loads that arise within automotive applications. Furthermore, the ease with which steel angles can be welded or bolted together grants designers and constructors flexibility when designing and constructing automotive components. On the whole, due to their strength, versatility, and capacity to withstand the industry's rigorous demands, steel angles represent a dependable and cost-effective choice for automotive applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Unequal Angle Steel Good Price SS400 Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords