Structure Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

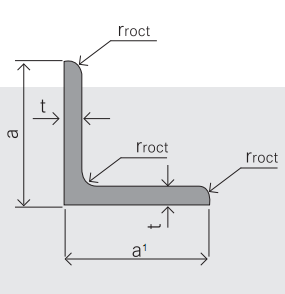

Specifications of Structure Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

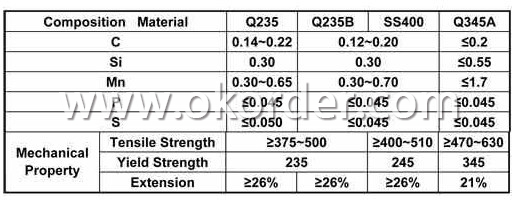

6. Material details:

Usage & Applications of Structure Angle Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Structure Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q:How do steel angles perform under vibration or resonance conditions?

- Steel angles are generally stable and perform well under vibration or resonance conditions. Due to their rigid structure and strong material properties, steel angles have a high resistance to vibrations and can effectively dampen resonance effects. This makes them suitable for various applications where stability and durability are required, such as in construction and engineering projects.

- Q:What is the difference between hot-rolled and cold-formed steel angles?

- Hot-rolled steel angles and cold-formed steel angles are both used in various construction and industrial applications, but they differ in their manufacturing processes and resulting characteristics. Hot-rolled steel angles are produced by heating a steel billet or slab above its recrystallization temperature and then passing it through a series of rollers to achieve the desired shape. This process allows for the formation of bends, curves, and other complex angles. Hot rolling also results in a rougher surface finish and a slightly rounded edge, which may be favorable in certain applications. Additionally, hot-rolled steel angles tend to have a wider range of sizes and thicknesses available. On the other hand, cold-formed steel angles are made by bending a flat strip of steel at room temperature using a series of dies and rolls. This process does not involve heating the steel, which maintains its existing physical properties. As a result, cold-formed steel angles have a smoother surface finish and sharper, more defined edges compared to hot-rolled angles. The cold-forming process also allows for tighter tolerances and more precise dimensions. In terms of mechanical properties, hot-rolled steel angles generally have higher tensile strength and yield strength compared to cold-formed angles. This is due to the heat treatment involved in hot rolling, which refines the grain structure and enhances the overall strength of the steel. Cold-formed steel angles, while usually less strong, are often preferred in applications where weight reduction is a priority, as they are generally lighter than their hot-rolled counterparts. In summary, the main differences between hot-rolled and cold-formed steel angles lie in their manufacturing processes, resulting surface finish, dimensional precision, and mechanical properties. The choice between the two depends on the specific requirements and constraints of the project at hand.

- Q:How do you prevent and address corrosion in steel angles?

- To prevent and address corrosion in steel angles, several measures can be taken. Firstly, applying a protective coating such as paint or galvanization can create a barrier between the steel and corrosive elements. Regular maintenance and inspection are also crucial to identify and address any signs of corrosion early on. Additionally, keeping the steel angles clean and dry, and avoiding contact with corrosive substances, can significantly reduce the risk of corrosion. Implementing proper drainage and ventilation systems in areas where steel angles are installed can also help prevent moisture buildup, which is a common cause of corrosion.

- Q:What are the different types of corrosion protection coatings for steel angles?

- For steel angles, there exists a variety of corrosion protection coatings that serve different purposes in safeguarding against corrosion. 1. Paint Coatings: Paint coatings are frequently employed for corrosion protection of steel angles. Acting as a barrier, they shield the steel surface from corrosive elements present in the surroundings. These coatings are typically applied in multiple layers and can be tailored to meet specific needs, such as resistance to chemicals or UV radiation. 2. Galvanizing: Another extensively used method for corrosion protection in steel angles is galvanizing. This process entails the application of a zinc layer to the steel surface through hot-dip galvanizing. By acting as a sacrificial anode, this coating provides excellent corrosion protection, sacrificing itself before the steel. Galvanized steel angles are commonly utilized in outdoor settings where exposure to moisture and harsh weather conditions is expected. 3. Powder Coatings: Powder coatings, which are applied as a dry powder and cured with heat, offer a durable and corrosion-resistant finish for steel angles. These coatings can be customized in terms of color, texture, and thickness, ensuring both aesthetic appeal and enhanced protection against corrosion. 4. Epoxy Coatings: Industrial applications often require the use of epoxy coatings when steel angles may be exposed to harsh chemicals or abrasive environments. These coatings form a robust and protective layer that resists corrosion, chemicals, solvents, and abrasion. They can be applied as a single layer or combined with other coatings for added protection. 5. Organic Coatings: In architectural applications where corrosion protection is necessary while maintaining an attractive appearance, organic coatings such as polyurethane or acrylic coatings are commonly used for steel angles. These coatings offer good resistance to weathering, UV radiation, and corrosion, ensuring the longevity of the steel angles. When selecting a corrosion protection coating for steel angles, it is crucial to consider the specific application, environmental conditions, and budget constraints. Seeking advice from corrosion specialists or coating suppliers can help determine the most suitable coating for the intended use.

- Q:Are steel angles suitable for scaffolding?

- Yes, steel angles are suitable for scaffolding. They are commonly used in scaffolding systems due to their strength, durability, and ability to provide stable support for workers and materials. Steel angles offer excellent load-bearing capacity and can withstand heavy loads, making them a reliable choice for scaffolding structures.

- Q:Can steel angles be used for support beams in warehouse construction?

- Steel angles have the capability to function as support beams in warehouse construction. They are widely employed as structural elements in diverse construction endeavors, including the construction of warehouses. They possess remarkable strength and endurance, rendering them suitable for carrying substantial loads and ensuring structural stability. Steel angles can be effortlessly fabricated and tailored to fulfill particular design necessities, making them an adaptable preference for constructing support beams in warehouse construction. Moreover, steel angles exhibit resistance to corrosion, a fundamental trait in warehouse settings where exposure to moisture and chemicals is prevalent. All things considered, steel angles present themselves as a dependable and cost-efficient alternative for support beams in warehouse construction.

- Q:Can steel angles be fire-resistant?

- Indeed, steel angles possess fire-resistant qualities. Being a material, steel inherently possesses fire resistance due to its high melting point and low thermal conductivity. When faced with elevated temperatures, steel angles can retain their structural integrity and withstand deformation for a significant duration. Furthermore, fire resistance in steel angles can be augmented through diverse approaches, such as the utilization of fire-resistant coatings or the integration of fire-resistant materials in their design. These measures serve to heighten the fire resistance capacity of steel angles, rendering them appropriate for scenarios where fire protection is imperative, such as the establishment of fire-resistant walls, ceilings, and structural systems in construction projects.

- Q:What is the cost of steel angles compared to other structural materials?

- The cost of steel angles compared to other structural materials can vary depending on factors such as the specific type of material, market conditions, and quantity needed. However, generally speaking, steel angles tend to be a cost-effective choice for structural applications due to their durability, strength, and versatility.

- Q:What is the typical corrosion rate of steel angles?

- The typical corrosion rate of steel angles can vary depending on various factors such as the environment, exposure to moisture, presence of corrosive substances, and maintenance practices. However, on average, steel angles can experience a corrosion rate of around 0.1 to 1.0 millimeters per year.

- Q:Can steel angles be used for fencing or gating?

- Yes, steel angles can be used for fencing or gating. Steel angles are often used in construction projects for their strength and durability. They can be used as posts or rails in fencing and gating systems, providing stability and support. Additionally, steel angles can be easily welded or bolted together to create various designs and configurations, making them a versatile choice for fencing and gating applications.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Structure Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords