Decorative Coated Aluminum Coil 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Decorative Coated Aluminum Coil 3003 H14

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Decorative Coated Aluminum Coil 3003 H14

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Decorative Coated Aluminum Coil 3003 H14

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

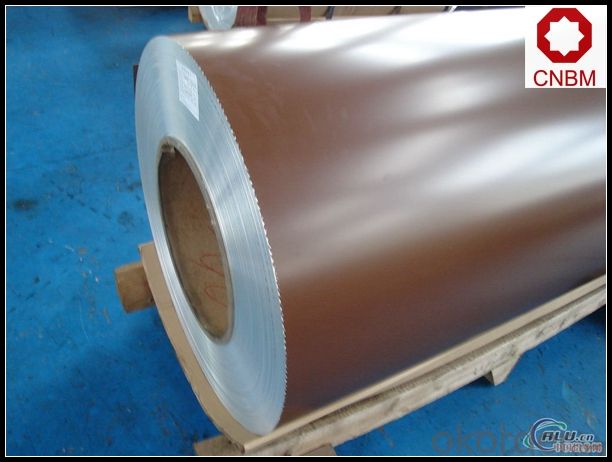

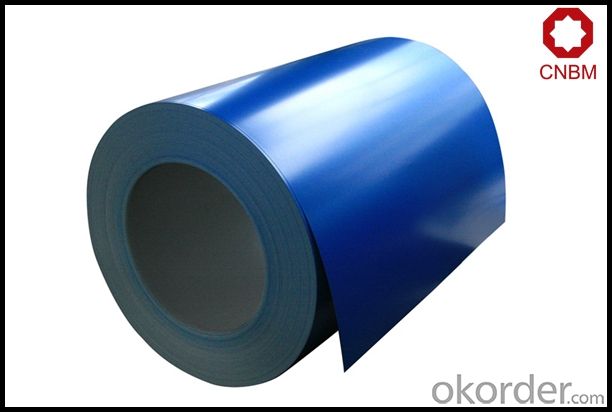

5. Image of Decorative Coated Aluminum Coil 3003 H14

6. Package and shipping of Decorative Coated Aluminum Coil 3003 H14

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What are the different thickness tolerances for aluminum coils?

- The different thickness tolerances for aluminum coils can vary depending on the specific grade and application. However, in general, the standard thickness tolerances for aluminum coils typically range from +/- 0.002 to 0.015 inches. This means that the actual thickness of the aluminum coil can deviate within these tolerances. The specific tolerance requirements may also be influenced by factors such as the intended use of the aluminum coil and the manufacturing process involved. It is important to consult the relevant industry standards and specifications to determine the specific thickness tolerances needed for a particular application.

- Q:Are aluminum coils susceptible to warping or bending?

- Yes, aluminum coils are susceptible to warping or bending. Aluminum, although lightweight and highly corrosion-resistant, is a relatively soft metal compared to other materials like steel. This means that it is more prone to bending or warping under certain conditions. Factors such as excessive heat, heavy loads, or improper handling can cause aluminum coils to deform. It is important to handle and store aluminum coils carefully to prevent any damage or distortion. Additionally, proper installation techniques and maintenance practices can help minimize the risk of warping or bending.

- Q:How are aluminum coils used in the production of gutters and downspouts?

- Aluminum coils play a crucial role in the production of gutters and downspouts. These coils are used as the primary material to manufacture seamless gutters, which are known for their durability, longevity, and aesthetic appeal. To begin the production process, the aluminum coils are fed into a specialized gutter machine. This machine shapes the coils into the desired gutter profile, typically in the form of a long continuous piece. The coil is then cut into appropriate lengths to match the measurements of the gutter system required for a specific building or project. Once cut, the aluminum coil is then shaped and formed using various bending and folding techniques. This allows the coil to be transformed into the seamless gutter shape needed to efficiently collect and channel rainwater away from the roof and foundation of a building. The seamless design eliminates the risk of leaks and enhances the overall functionality of the gutter system. Additionally, the aluminum coils used in gutter production offer several advantages. Firstly, aluminum is lightweight yet sturdy, making it an ideal material for gutters and downspouts. It is resistant to rust and corrosion, ensuring the longevity of the gutter system even in harsh weather conditions. Furthermore, aluminum is highly malleable, allowing for customized shapes and sizes to fit the specific requirements of different buildings. In conclusion, aluminum coils are an integral component in the production of gutters and downspouts. They are used to create seamless gutters that are aesthetically pleasing, durable, and highly functional. The use of aluminum as the primary material ensures long-lasting performance, resistance to corrosion, and customization options for various architectural needs.

- Q:What are the common testing methods for aluminum coils?

- There are several common testing methods for aluminum coils that are used to ensure their quality and performance. These methods include: 1. Visual inspection: This involves a thorough examination of the coils for any visible defects such as dents, scratches, or surface irregularities. Visual inspection is a basic and initial step in the testing process. 2. Dimensional measurement: This method involves measuring the dimensions of the aluminum coils to ensure they meet the specified requirements. This includes measuring the length, width, and thickness of the coils. 3. Tensile testing: Tensile testing is performed to assess the mechanical properties of the aluminum coils, such as their strength and elasticity. This test involves applying a tensile force to a sample of the coil until it breaks or deforms, allowing for the determination of its tensile strength. 4. Hardness testing: The hardness of aluminum coils is an important factor in determining their suitability for specific applications. Various hardness testing methods, such as Rockwell or Brinell hardness tests, can be used to measure the resistance of the coil's surface to indentation or scratching. 5. Chemical composition analysis: This method involves analyzing the chemical composition of the aluminum coil to ensure it meets the required specifications. Common techniques used for this analysis include spectroscopy or X-ray fluorescence (XRF) analysis. 6. Corrosion resistance testing: Aluminum coils are often exposed to harsh environmental conditions, so assessing their resistance to corrosion is crucial. This can be done through various tests like salt spray testing or electrochemical impedance spectroscopy (EIS) to determine the coil's ability to withstand corrosion. 7. Coating quality assessment: If the aluminum coil is coated with a protective layer, testing methods such as adhesion testing, coating thickness measurement, or impact resistance testing can be used to ensure the quality and durability of the coating. These are some of the most common testing methods employed for aluminum coils. By conducting these tests, manufacturers can ensure that the coils meet the required standards and perform optimally in their intended applications.

- Q:How are aluminum coils made?

- Aluminum coils are made through a process called continuous casting and rolling. First, pure aluminum is heated and melted in a furnace. Then, the molten aluminum is poured through a curved mold with a small opening at the bottom, where it solidifies into a long, thin strip. This strip is then passed through a series of rolling mills, where it is gradually reduced in thickness and lengthened to form a coil. The coils are then cooled, inspected, and ready to be used in various industries such as construction, automotive, and packaging.

- Q:How do aluminum coils perform in extreme weather conditions?

- Aluminum coils are known for their excellent performance in extreme weather conditions. Due to their inherent properties, aluminum coils are highly resistant to corrosion, making them ideal for use in areas with high humidity, coastal regions, and places prone to acid rain or industrial pollution. Additionally, aluminum coils have a high melting point, which allows them to withstand extreme heat without warping or deforming. In extremely cold weather, aluminum coils exhibit exceptional durability and do not become brittle like some other materials. They are capable of maintaining their structural integrity, ensuring optimal performance even in freezing temperatures. Moreover, aluminum coils have excellent thermal conductivity, making them efficient in transferring heat and defrosting capabilities, which is crucial for HVAC systems operating in cold weather conditions. In hot and humid climates, aluminum coils excel in resisting corrosion, preventing moisture buildup, and maintaining their efficiency. They are designed to withstand high humidity levels, preventing the growth of mold or bacteria that could compromise indoor air quality. The lightweight nature of aluminum coils also contributes to their ability to dissipate heat quickly, improving overall cooling performance and energy efficiency. Furthermore, aluminum coils are highly durable and can withstand extreme weather events such as hurricanes, strong winds, and hailstorms. They are designed to be robust and resistant to impact, ensuring that they can withstand harsh weather conditions without sustaining damage. Overall, aluminum coils have proven to be reliable and effective in extreme weather conditions, providing long-lasting performance and durability. Their resistance to corrosion, ability to withstand high and low temperatures, and capacity to withstand severe weather events make them an excellent choice for various applications, including HVAC systems, refrigeration units, and outdoor equipment.

- Q:Are aluminum coils resistant to UV radiation?

- Yes, aluminum coils are generally resistant to UV radiation. Aluminum has a natural oxide layer that provides protection against UV rays, making it highly durable and suitable for outdoor applications.

- Q:What is the role of aluminum coils in the construction of ships?

- The marine industry heavily relies on aluminum coils for the construction of ships. These coils are essential in manufacturing various ship components and structures. The lightweight nature of aluminum coils is a significant advantage in ship construction. Compared to traditional steel, aluminum is much lighter, resulting in improved fuel efficiency and overall performance of the ship. This is particularly beneficial for larger vessels, as reducing weight helps minimize energy consumption and operating costs. Furthermore, aluminum coils offer outstanding resistance to corrosion, making them ideal for the harsh marine environment. Ships constantly face exposure to corrosive saltwater, which can deteriorate metal materials. By utilizing aluminum coils, shipbuilders can ensure that their vessels are well-protected against rust and corrosion, ultimately extending their lifespan and reducing maintenance needs. Additionally, aluminum coils are easily shaped and formed into various structures, providing shipbuilders with greater design flexibility. This versatility allows for the creation of intricate ship components like hulls, superstructures, and bulkheads. Aluminum's excellent weldability also simplifies the process of joining different sections of the ship, resulting in more efficient and streamlined construction. Moreover, aluminum is a highly sustainable material. It can be recycled without any loss in quality or performance, making aluminum coils an environmentally friendly choice for ship construction. This aligns with the increasing focus on sustainability in the industry. In conclusion, aluminum coils play a multifaceted role in ship construction. They offer lightweight, corrosion-resistant, and easily formable materials that contribute to improved fuel efficiency, durability, and design flexibility. Additionally, their recyclability makes them an environmentally conscious option. Overall, aluminum coils are a vital component in building efficient, durable, and sustainable ships.

- Q:also, can aluminum become oxidized when secured down with metal nuts and bolts vice stainless steel nuts and bolts?

- there is not any way which you will develop right into a mermaid.. you may now have gills surgically put in on your physique... yet as for the rest that is not any longer achievable for there are nevertheless issues that for the period of common terms nature ought to do... And shall we no longer forget that guy-type and mermaids have been enemies for hundreds of years... and you need to get caught in some fisherman internet and land up as dogs nutrition.... Or a attempt subject in some international places laboratory And ingesting uncooked sea-nutrition for the the remainder of your organic life my no longer be your component........ yet on no account the fewer solid success in having your dream come actual.......................

- Q:What kind of sensor is appropriate for aluminum coil thickness measurement?

- Use two sensors of ZLDS10X series to make a thickness gauge

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Decorative Coated Aluminum Coil 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords