seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

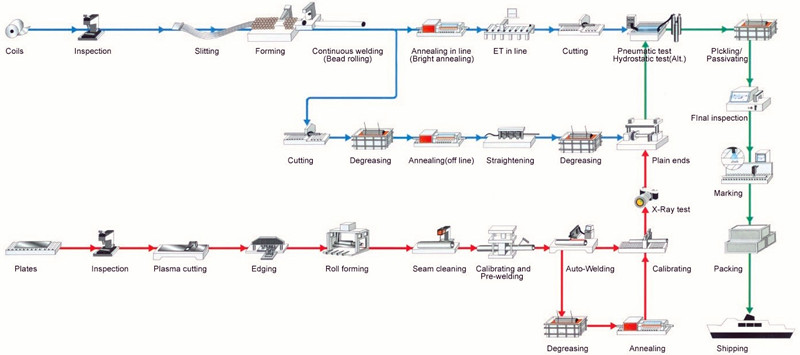

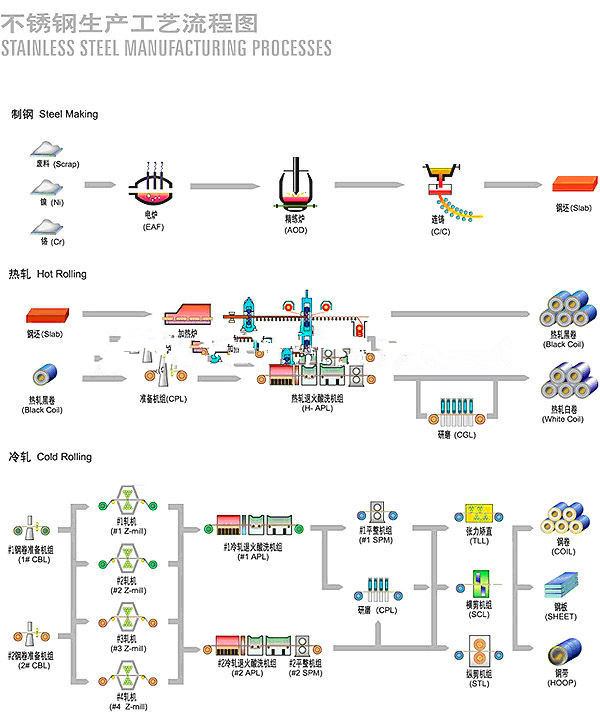

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:60.3*3.91 mm or others

2.Surface: NO.1

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q:What are the different types of stainless steel pipe caps?

- Various industries utilize different types of stainless steel pipe caps for various purposes. There are several common types: 1. Welded Pipe Caps: These caps are welded onto the pipe's end to create a secure and leak-proof seal. They are ideal for high-pressure applications that require a robust connection. 2. Threaded Pipe Caps: These caps have internal threads that allow them to be screwed onto a threaded pipe's end. They are commonly used in low-pressure applications and can be easily removed for maintenance or cleaning. 3. Socket Weld Pipe Caps: These caps have a socket on one end that fits over the pipe's end and is then welded to create a tight seal. They are typically used in high-temperature and high-pressure applications. 4. Butt Weld Pipe Caps: These caps are similar to socket weld caps, but instead of a socket, they feature a butt weld connection. They are commonly used in large-diameter pipes and are renowned for their strength and durability. 5. Compression Pipe Caps: These caps are designed for use with compression fittings, which are frequently used in plumbing and gas supply systems. They provide a tight seal without requiring welding or threading. 6. Flanged Pipe Caps: These caps have a flange on one end that allows them to be bolted onto a flanged pipe's end. They are often used in piping systems that necessitate frequent disassembly and reassembly. Each type of stainless steel pipe cap offers its own advantages and is suitable for specific applications. It is crucial to select the appropriate cap based on the project requirements to ensure a proper and secure fit.

- Q:Can stainless steel pipes be recycled?

- Yes, stainless steel pipes can be recycled. Stainless steel is a highly recyclable material due to its durability and corrosion resistance. When stainless steel pipes reach the end of their useful life or are no longer needed, they can be collected, processed, and melted down to create new stainless steel products. Recycling stainless steel pipes not only helps conserve natural resources but also reduces energy consumption and emissions associated with mining and manufacturing new materials.

- Q:What is the difference between bright annealed and annealed pickled stainless steel pipes?

- Bright annealed and annealed pickled stainless steel pipes differ in their surface finish and treatment processes. Bright annealed stainless steel pipes undergo a heat treatment known as annealing in a controlled atmosphere to eliminate internal stresses and improve the material's ductility. This process also results in a bright and shiny surface finish, making the pipes suitable for applications that require an aesthetically pleasing appearance, such as decorative or architectural purposes. On the other hand, annealed pickled stainless steel pipes undergo a two-step treatment process. First, the pipes are annealed to remove any stresses and improve their mechanical properties. Then, they undergo a pickling process where the surface is chemically treated to remove scale, oxides, and other impurities. This treatment leaves the pipes with a dull and rough surface finish, which is often desired for applications that require subsequent coatings, such as painting or galvanizing. In summary, the main difference between bright annealed and annealed pickled stainless steel pipes lies in their surface finish. Bright annealed pipes have a bright and shiny appearance, while annealed pickled pipes have a dull and rough surface finish due to the pickling process. The choice between the two types depends on the specific requirements of the intended application.

- Q:Can stainless steel pipes be wrapped with fiberglass insulation?

- Yes, stainless steel pipes can be wrapped with fiberglass insulation. Fiberglass insulation is commonly used to insulate various types of pipes, including stainless steel pipes. It helps to reduce heat loss and maintain the temperature of the pipe, making it more energy efficient. Additionally, fiberglass insulation also provides soundproofing and condensation control benefits. When wrapping stainless steel pipes with fiberglass insulation, it is important to ensure that the insulation is properly installed and sealed to prevent any gaps or air leaks. This will optimize the insulation performance and ensure maximum energy savings.

- Q:Can stainless steel pipes be insulated with fiberglass?

- Fiberglass insulation is a viable option for insulating stainless steel pipes. Its exceptional thermal resistance characteristics make it a popular choice for pipe insulation. By preventing heat loss or gain, it enhances energy efficiency. Moreover, fiberglass insulation is lightweight, simple to install, and can be easily customized to fit pipes of different sizes and shapes. It also offers excellent sound insulation properties and is non-combustible. Thus, fiberglass insulation is the ideal solution for insulating stainless steel pipes.

- Q:Stainless steel and stainless steel pipe inside and outside polishing off, what is the difference?

- Ordinary stainless steel is in the chemical grade, and the ordinary pickling surface looks white. Mainly used in petrochemical, sewage treatment and other industries.

- Q:Can stainless steel pipes be magnetized?

- Stainless steel pipes have the potential to be magnetized to some degree, although they are generally considered non-magnetic unlike ferromagnetic substances like iron or nickel. This is due to the presence of a substantial amount of chromium, which creates a protective oxide layer on the steel's surface, making it resistant to magnetization. Nevertheless, stainless steel can still exhibit a slight attraction to a magnet, particularly if it has undergone specific processes like cold working or welding. These procedures can alter the steel's crystalline structure, enabling it to acquire a slight magnetic quality. It is important to emphasize that the magnetic force in stainless steel pipes is relatively weak and will not possess the same level of magnetism or ability to attract other magnetic objects as ferromagnetic materials would.

- Q:What are the different finishes available for stainless steel pipes?

- Stainless steel pipes come in various finishes, each offering a distinct appearance and level of protection against corrosion. 1. Brushed Finish: By utilizing a fine abrasive material, the surface of the stainless steel pipe is brushed to create a textured and dull look. This finish effectively conceals scratches and fingerprints, making it a popular choice for projects that prioritize aesthetics, such as architectural designs. 2. Mirror Finish: Also referred to as a polished or reflective finish, this option involves polishing the surface of the stainless steel pipe to achieve a highly reflective shine. It provides a smooth and easily cleanable surface, commonly used for decorative purposes like handrails and furniture. 3. Satin Finish: Similar to the brushed finish, the satin finish employs a fine abrasive material to create a smooth and dull appearance. It offers a slightly more refined look compared to the brushed finish and is frequently utilized in applications where corrosion resistance is crucial, such as the food and beverage industry. 4. Embossed Finish: This finish entails imprinting a pattern onto the surface of the stainless steel pipe, adding texture and visual interest. It is often employed in decorative applications like wall panels or elevator interiors. 5. Bead Blasted Finish: Achieved by propelling small glass beads at high pressure onto the stainless steel pipe's surface, this finish creates a uniform and matte appearance. It is commonly used in architectural projects as it provides a unique texture and effectively conceals fingerprints. 6. Passivated Finish: The passivation process involves chemically removing contaminants from the surface of the stainless steel pipe to enhance its corrosion resistance. This finish is frequently employed in applications where the pipes are exposed to harsh environments or chemicals. It is crucial to consider the specific application and aesthetic preferences when selecting a finish for stainless steel pipes. Each finish has its own pros and cons, so factors like durability, maintenance, and the intended use of the pipe should be taken into account before making a decision.

- Q:Can stainless steel pipes be used in the renewable energy industry?

- Yes, stainless steel pipes can be used in the renewable energy industry. Stainless steel is corrosion-resistant, durable, and able to withstand high temperatures and pressures, making it suitable for various applications in renewable energy systems such as solar thermal, geothermal, and biomass. It is commonly used for transporting fluids, gases, and steam in these systems, ensuring reliable and efficient energy production.

- Q:Can stainless steel pipes be used for structural purposes?

- Certainly, structural purposes can indeed employ stainless steel pipes. Stainless steel, renowned for its strength, durability, and resistance to corrosion, proves to be an exceptional substance for structural uses. Found commonly in industries like construction, architecture, and engineering, stainless steel pipes serve as structural support and facilitate the conveyance of fluids and gases. They possess the capability to endure heavy loads, extreme temperatures, and even harsh environmental circumstances, rendering them fitting for an extensive array of structural applications. Furthermore, stainless steel pipes offer customization options through various grades, sizes, and thicknesses, enabling them to cater to specific structural prerequisites.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords