E-glass Fiberglass Woven Roving 400gsm-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

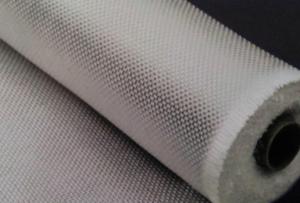

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q:Is fiberglass mat tissue suitable for automotive interiors?

- Automotive interiors can benefit from the use of fiberglass mat tissue. This versatile material is widely utilized in many industries, including automotive manufacturing. It possesses several advantages that make it appropriate for car interiors. To begin with, fiberglass mat tissue offers excellent insulation capabilities. It effectively reduces noise, vibration, and harshness (NVH) levels inside the vehicle cabin. This greatly enhances passenger comfort and the overall driving experience. Moreover, fiberglass mat tissue is lightweight and flexible, making it easy to install in different areas of the car's interior. It can be molded and shaped to fit various components like door panels, headliners, trunk liners, and floor carpets. Its flexibility also allows for seamless integration with other materials, such as sound-deadening substances, to further improve insulation and minimize vibrations. Additionally, fiberglass mat tissue exhibits resistance to heat, moisture, and chemicals commonly found in automotive environments. This renders it a durable and long-lasting material capable of withstanding the unique conditions inside a vehicle. It also resists the growth of mold and mildew, ensuring a clean and hygienic interior. Furthermore, fiberglass mat tissue can be easily coated or laminated with other materials to enhance its aesthetic appeal. It can be finished with various fabrics, vinyl, or leather to match the desired interior design and provide a luxurious feel. In conclusion, fiberglass mat tissue is a suitable material for automotive interiors due to its insulation properties, lightweight and flexible nature, durability, resistance to heat and moisture, and potential for aesthetic enhancements. Its utilization contributes to the creation of a comfortable, quiet, and visually pleasing cabin space for vehicle occupants.

- Q:Can fiberglass mat tissue be used in structural applications?

- Yes, fiberglass mat tissue can be used in structural applications. Fiberglass mat tissue is a lightweight and flexible material that is commonly used as reinforcement in construction and engineering. It is often used in conjunction with other materials such as resin or concrete to enhance the structural integrity of various components. The high strength-to-weight ratio of fiberglass mat tissue makes it ideal for reinforcing structures such as walls, roofs, and floors. Additionally, fiberglass mat tissue is resistant to corrosion, moisture, and chemicals, making it suitable for use in various environments. Its versatility and durability make it a popular choice in structural applications.

- Q:Can fiberglass mat tissue be used in marine applications?

- Yes, fiberglass mat tissue can be used in marine applications. It is commonly used in boat building and repair due to its excellent strength, corrosion resistance, and durability in marine environments.

- Q:Is fiberglass mat tissue suitable for soundproofing?

- Yes, fiberglass mat tissue is suitable for soundproofing. It is an effective material for absorbing and dampening sound waves, making it a popular choice for soundproofing applications in buildings, vehicles, and other structures.

- Q:Can fiberglass mat tissue be used for insulation in shopping malls?

- Indeed, insulation in shopping malls can incorporate the utilization of fiberglass mat tissue. This material is widely employed and proven to be efficient for thermal insulation owing to its low thermal conductivity and exceptional resistance to heat transfer. Moreover, fiberglass mat tissue possesses the advantage of being non-combustible, rendering it a secure choice for commercial structures such as shopping malls. Furthermore, its lightweight nature facilitates effortless installation, and its superb sound absorption properties contribute to establishing a pleasant and serene ambiance in the mall. All in all, fiberglass mat tissue emerges as an appropriate selection for insulation in shopping malls, ensuring energy efficiency and enhanced indoor comfort.

- Q:Is fiberglass mat tissue suitable for insulation in residential buildings?

- Yes, fiberglass mat tissue is suitable for insulation in residential buildings. Fiberglass mat tissue is a type of insulation material that is made from glass fibers and is commonly used in residential buildings due to its excellent thermal properties. It has a high R-value, which means it provides effective insulation by reducing heat transfer, keeping the interior of the building warm during winter and cool during summer. Fiberglass mat tissue is also known for its durability and long lifespan, making it a reliable choice for residential insulation. It is resistant to moisture, mold, and pests, ensuring a healthy and comfortable living environment. Additionally, fiberglass mat tissue is lightweight and easy to install, making the insulation process efficient and cost-effective. Furthermore, fiberglass mat tissue is fire-resistant, which is an essential feature for residential buildings. It acts as a barrier, preventing the spread of fire and protecting the occupants and property from potential hazards. Overall, fiberglass mat tissue is a suitable and popular choice for insulation in residential buildings due to its thermal efficiency, durability, fire-resistant properties, and ease of installation.

- Q:Is fiberglass mat tissue suitable for insulation in sports facilities?

- Fiberglass mat tissue is indeed suitable for insulation in sports facilities. Fiberglass is a commonly used material for insulation due to its excellent thermal properties and fire resistance. It provides effective insulation, keeping the indoor environment comfortable by reducing heat loss or gain. Additionally, fiberglass insulation is lightweight, durable, and easy to install, making it ideal for sports facilities where large areas need to be insulated. It is also resistant to moisture and does not promote the growth of mold or mildew, ensuring a healthy and hygienic environment. Overall, fiberglass mat tissue is a reliable and efficient option for insulation in sports facilities.

- Q:How does fiberglass mat tissue perform in terms of acoustic insulation?

- When it comes to acoustic insulation, fiberglass mat tissue excels. Its fine fiber composition allows it to effectively absorb sound waves and minimize airborne noise transmission. The dense structure of the mat tissue enhances its soundproofing capabilities, making it a top choice for situations where noise control is essential. Furthermore, fiberglass mat tissue also boasts superior thermal insulation properties, further enhancing its acoustic insulation performance. In summary, this material is highly effective at reducing sound transmission and creating tranquil environments.

- Q:What are the different reinforcement orientations available for fiberglass mat tissue?

- There are several different reinforcement orientations available for fiberglass mat tissue, each serving a specific purpose in various applications. One common orientation is the unidirectional reinforcement, where the fibers are aligned in one direction. This orientation provides high strength and stiffness in the direction of alignment, making it suitable for applications that require resistance to tension or bending forces in a single direction. Another orientation is the bidirectional reinforcement, where the fibers are aligned in two perpendicular directions. This orientation provides equal strength and stiffness in both directions, making it ideal for applications that require resistance to both tension and compression forces. Bidirectional reinforcement is commonly used in structural components such as panels, pipes, and tanks. A third orientation is the randomly oriented reinforcement, where the fibers are distributed in a random manner. This orientation offers isotropic properties, meaning it provides similar strength and stiffness in all directions. Random reinforcement is often used in applications that require uniform strength and flexibility, such as automotive parts, boat hulls, and sporting goods. Additionally, there are also hybrid reinforcement orientations available, which combine different types of fibers or orientations to achieve specific performance requirements. These hybrid reinforcements can offer a combination of strength, stiffness, flexibility, and other desired properties, making them suitable for a wide range of applications. Overall, the choice of reinforcement orientation for fiberglass mat tissue depends on the specific requirements of the application, including the desired mechanical properties, the direction of forces to be resisted, and other performance considerations.

- Q:Can fiberglass mat tissue be used for reinforcing fiberglass pools?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass pools. It helps enhance the strength and durability of the pool structure by providing added reinforcement to the fiberglass layers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Woven Roving 400gsm-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords