Aluminum pallet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

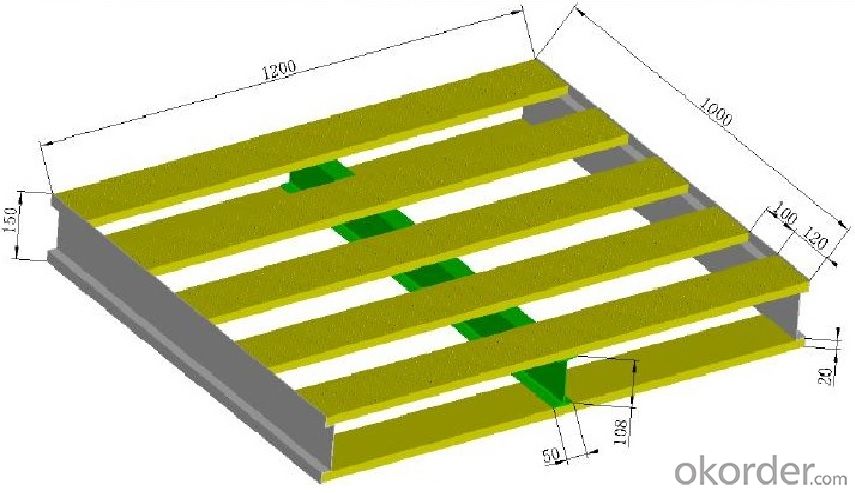

Please see more info as belows:

No. | Dimension(mm) | Weight(kg) | Alloy | Dynamic load | Static load | Load mode | Processing type |

1 | 1200×1000×153 | 14.84 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

2 | 1200×1000×150 | 14.38 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

3 | 1200×1000×150 | 21.56 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

4 | 1200×800×150 | 11.90 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

5 | 1200×800×150 | 17.62 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

6 | 1100×1100×150 | 14.39 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

7 | 1100×1100×150 | 20.96 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

8 | 1200×1000×150 | 14.13 | AL6061-T6 | 1.5t | 3t | Single side | Riveting |

9 | 1200×1000×150 | 18.60 | AL6061-T6 | 1.5t | 3t | Double side | Riveting |

- Q:What are the different types of aluminum pipes available?

- There are several different types of aluminum pipes available, including seamless pipes, welded pipes, and extruded pipes. Seamless pipes are made by piercing a solid aluminum billet to create a hollow tube with no seams. Welded pipes are formed by joining two or more pieces of aluminum together using welding techniques. Extruded pipes are created by pushing heated aluminum through a die to achieve the desired shape and size. Each type of aluminum pipe has its own unique properties and applications.

- Q:What is the average lifespan of aluminum pipes?

- The lifespan of aluminum pipes can vary due to factors such as material quality, usage environment, and maintenance. On the whole, aluminum pipes have a long lifespan and can endure for many decades. By installing them correctly, conducting regular inspections, and making timely repairs, aluminum pipes can fulfill their intended purpose for 30 to 50 years or more. Nevertheless, it is crucial to acknowledge that external elements like corrosion, exposure to harsh chemicals, or extreme temperature fluctuations can greatly affect the lifespan of aluminum pipes. Hence, regular maintenance and periodic assessments are necessary to guarantee the durability and effectiveness of aluminum pipes.

- Q:How can the refrigerator be welded with copper aluminum tube?

- 1) prior to the expansion of copper aluminum tube (caliber size to M51 welding wire can be very good penetration into the copper aluminum pipe border is appropriate), the copper tube into the aluminum tube, it is best to polish the surface of the dirty material.2) apply the equivalent M51-F flux at the weld and heat the base material until the surface M51-F flux boils, indicating that the working temperature of the M51 wire has reached 179 degrees.3) after the M51-F flux boils, the M51-F wire is fused with the M51 wire by the temperature of the base metal. At this point, continue to heat the base metal to compensate for the loss of heat, because copper and aluminum are very good heat conductors. Here, because there is a continuous heating process, M51-F has a process of evaporation and dissipation. When the base metal surface is dry and without flux, please use M51 welding wire with M51-F flux to drip on the welding surface.4) when the M51 wire is fully flowing, let it cool slowly and naturally. Surface fluxes are easily removed with warm water.

- Q:How do you weld aluminum plate and aluminium tube?

- Before determining and selecting the welding process for aluminium tubes and aluminium sheets, the following matters shall be determined:1. aluminum tube and aluminum plate metal material grade, according to your aluminum tube and aluminum plate material performance, joint use conditions and corrosion resistance, choose welding materials;2. aluminum tube and aluminum sheet metal properties;3. mechanical properties or strength, tensile strength and shear strength required for welded joints;4. welding joint working conditions, such as corrosion resistance.According to the above characteristics, choose the welding method for aluminum pipe and aluminum plate. At present, the main methods of welding aluminium tube and aluminium plate are:1. high frequency induction brazing: high frequency induction heating is used to melt the solder. The cost is low, and the use is convenient. At present, this process is used in many industries to braze the aluminum tube and aluminum plate;2. diffusion welding: generally used rarely, mainly for surface bonding;3. flame brazing: lower cost.

- Q:What are the benefits of an aluminum tube cigar?

- The best start glass tube, sealed to preserve the original flavor

- Q:Is the tube of LED lamp all plastic tube well or half plastic half aluminium tube?

- Of course, the power is placed inside the aluminum tube, so that the amount of LED heating plus the heating capacity of the power supply is considerable, because the power of this lamp is usually around 20W. If the power is bigger, half of the aluminum tube can not solve its heat dissipation problem. It also proposed another aluminum tube cooling fan: shaped tubes. The fan shaped aluminum frame with heat dissipation structure shape, greatly increasing the radiator area. It puts the power outside the tube so that the half of the aluminum shell is completely made into a radiator. Relative to the semicircular aluminum tube, its heat dissipation area has increased by more than 3 times. Coupled with the power does not put in the tube, but also to reduce heat, which greatly extended the life of LED.

- Q:6063, aluminum pipe bending performance, hardness of the best value?

- Three is energy-saving advantages: air conditioner indoor machine and outdoor machine connection pipeline, heat transfer efficiency is lower, more energy saving, or, the better insulation effect, the more power saving.Four is the bending performance, easy installation and removal

- Q:Do aluminum pipes have any specific limitations in terms of length?

- Aluminum pipes do have certain limitations in terms of length, but these limitations are typically dependent on various factors such as the diameter, thickness, and intended application of the pipe. One limitation is the potential for buckling or collapse under excessive weight or pressure. Longer aluminum pipes may be more prone to these issues, especially if they have a smaller diameter or thinner walls. Proper engineering and design considerations can help mitigate this limitation by selecting appropriate pipe dimensions and reinforcement methods. Additionally, the expansion and contraction of aluminum with temperature changes can also impact the length limitations of pipes. Aluminum has a relatively high coefficient of thermal expansion, meaning it expands and contracts significantly more than other materials such as steel. This can lead to stresses and potential damage if not properly accounted for, particularly in longer pipes where temperature differentials may be more pronounced. Lastly, transportation and handling can pose limitations on the length of aluminum pipes. Longer pipes may be more difficult to transport and maneuver due to their size and weight. Specialized equipment or techniques may be required to ensure safe and efficient handling. In summary, while aluminum pipes do have limitations in terms of length, these limitations can be addressed through proper engineering, design considerations, and handling techniques. It is important to consult with experts and adhere to industry standards to ensure the safe and effective use of aluminum pipes in any given application.

- Q:Do you use seamless pipes or aluminium tubes for cold storage?

- Cold storage with aluminum tube is better. Because: the heat exchange of aluminum is faster than steel, so the cooling speed is faster, the cost is almost the same as the steel row, aluminum will not rust, so the latter does not need steel platoon to do the rust prevention maintenance.Cold storage is mainly used for constant temperature storage air conditioning equipment for food, dairy products, meat, aquatic products, cold storage is actually a kind of low temperature refrigerator (freezer) also belongs to the refrigeration equipment and a refrigerator compared to the cooling area should be large, but they have communicated with the refrigeration principle.

- Q:Are aluminum pipes suitable for vacuum systems?

- Depending on the specific requirements and conditions of the system, aluminum pipes can be suitable for vacuum systems. Aluminum is a lightweight and corrosion-resistant material, which makes it a popular choice for a variety of applications, including vacuum systems. However, it is important to consider factors such as the level of vacuum needed, the temperature range, and the potential for outgassing. In certain instances, aluminum may not be the optimal choice, particularly for high vacuum applications or systems that require extremely low levels of outgassing. In such cases, materials like stainless steel or titanium might be more appropriate. It is essential to consult experts or engineers who specialize in vacuum systems to determine the most suitable material for a specific vacuum system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum pallet

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords