Norwex Stainless Steel Cloth

Norwex Stainless Steel Cloth Related Searches

Stainless Steel Cloths Hardware Cloth Stainless Steel Stainless Steel Clothes Rack Stainless Steel Sleeve Stainless Steel Wool Stainless Steel Gloves Stainless Steel Washer Stainless Steel Farberware Stainless Steel Luggage Sheet Of Stainless Steel Stainless Steel Furniture Stainless Steel Shelving Farberware Stainless Steel Stainless Steel Wallet Stainless Steel Drying Rack Stainless Steel Diswasher Stainless Steel Wash Tub Cloth Strainer Stainless Steel Neckless Stainless Steel Glue Stainless Steel Kitchenware Stainless Steel Strap Stainless Steel Tape Stainless Steel Shelves Thermos Stainless Steel Stainless Steel Sheeting Stainless Steel Tote Stainless Steel Straw Shelving Stainless Steel Stainless Steel LocketNorwex Stainless Steel Cloth Supplier & Manufacturer from China

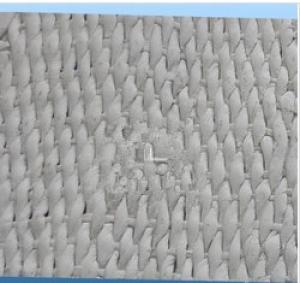

Norwex Stainless Steel Cloth is a high-quality cleaning product designed to effectively remove stubborn stains and grime from various surfaces without the need for harsh chemicals. This eco-friendly cloth is made from a unique blend of microfiber and stainless steel threads, which work together to break down and lift dirt and grease, leaving surfaces spotless and shining.The Norwex Stainless Steel Cloth is versatile and can be used in a wide range of applications, from cleaning kitchen countertops and appliances to removing scuff marks from floors and tiles. It is also ideal for polishing stainless steel, chrome, and other metal surfaces, as well as glass and mirrors. The cloth's abrasive properties make it perfect for tackling tough, baked-on messes, while its soft microfiber side gently buffs surfaces to a gleaming finish. This dual-action cleaning power ensures that the Norwex Stainless Steel Cloth can handle a variety of cleaning tasks with ease.

Okorder.com is a reputable wholesale supplier of the Norwex Stainless Steel Cloth, offering a large inventory of this popular cleaning product at competitive prices. With a commitment to providing high-quality goods and excellent customer service, Okorder.com is the ideal choice for businesses and individuals looking to stock up on this effective and environmentally friendly cleaning solution.

Hot Products