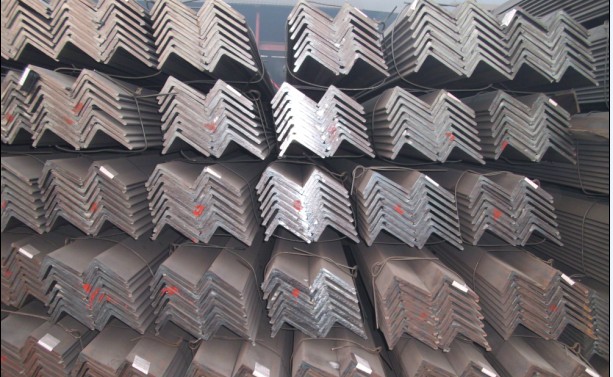

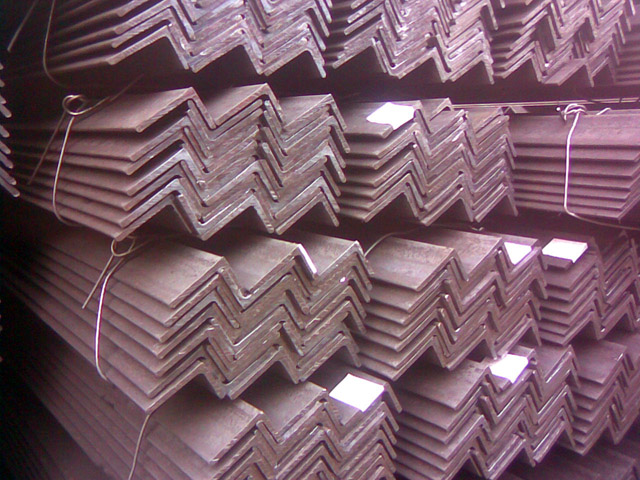

Unequal Stainless Steel 304 Angle Bars or Angle Iron Steel Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High alloy stainless steel with excellent high-temperature oxidation resistance and high-temperature strength.Specifications

stainless steel angle

Certification: ISO

Place of Origin: Shanxi, China (Mainland)

Model Number: angle bar

Standard: AISI, ASTM, DIN, GB, JIS

stainless steel angle

| Product | Competitive price stainless steel angle |

| Product classification | Equal Angle Steel & Unequal Angle Steel |

| Production Technics | Hot rolled,cold-bend |

| Productivity | 300,000 Mt/Year |

| Main Material | cold drawn stainless steel bar: Dia 1.0-12.0mm,bright surface. hot rolled stainless steel bar: Dia 14.0-150mm,black surface. forged stainless steel bar: Dia 150-350mm, unsmooth surface. |

| Surface treatment | hot dip galvanised or cold dip galvanised |

| Specification | (20*20*2mm)-(200*200*25mm) |

| Theoretical weight per meter | =0.00785*(width+width-thickness)*thickness |

| Application | widely used in Power tower, communication tower, railway, highway, street lamp pole, marine parts, construction steel structure component, handling machinery ,Container frame , warehouse ,reaction tower,the substation ancillary facilities, light industry etc. |

| Length | 6m-12m as you require |

Stainless Steel Angle Bar

1. Material grade:

cold drawn stainless steel bar: Dia 1.0-12.0mm,bright surface.

hot rolled stainless steel bar: Dia 14.0-150mm,black surface.

forged stainless steel bar: Dia 150-350mm, unsmooth surface.

2. Standard: ASTM A276,A484,A564,A581,A582,EN10272,JIS4303,JIS G 431,JIS G 4311,JIS G 4318,stainless steel angle bar

3. Production procedure: raw elements(C,Fe,Ni,Mn,Cr,Cu etc.,)-- smelted ingots by AOD finery-- hot rolled into black surface--pickling into acid liquid--cutting into pieces--checking quality--package

4. Surface: black,pickling,polish, etc ., stainless steel angle bar

5. Common sizes we have large stocks,diameter from 10mm*10mm*2mm-300mm*300mm*20mm

6. Usage:stainless steel angle bar is widely used in chemical, shipping,architecture,machine-made, household products industry, etc.

Definition of stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steelalloy with a minimum of 10.5% to 11% chromium content by mass.

Stainless steel does not readily corrode, rust or stain with water as ordinary steel does, but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity, or poor circulation environments. It is also called corrosion-resistant steel or CRES when the alloy type and grade are not detailed, particularly in the aviation industry. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and resistance to corrosion are required.

- Q: What is the typical shear strength of steel angles?

- The typical shear strength of steel angles can vary depending on several factors such as the grade of steel, the size and shape of the angle, and the specific application or industry standards being followed. However, in general, steel angles are known for their high shear strength. For standard structural steel angles, the shear strength can range from approximately 50,000 pounds per square inch (psi) to 75,000 psi. This range applies to common steel grades such as A36, A572, and A588. These angles are commonly used in construction, infrastructure, and engineering projects where shear forces are a concern. It is important to note that the shear strength of steel angles can be influenced by other factors such as the presence of holes or notches, welding or fabrication processes, and the overall design and load distribution. Therefore, it is crucial to consult relevant design codes or engineering specifications to determine the specific shear strength requirements for a given application. It is also recommended to consult with a structural engineer or experienced professional to ensure the accurate determination of shear strength for steel angles in a particular project.

- Q: What are the different types of steel angles used in agriculture?

- There are several types of steel angles used in agriculture, including equal angles, unequal angles, and L-shaped angles. These angles are commonly used in the construction of agricultural buildings, equipment, and fencing.

- Q: What are the typical lengths of steel angles available in the market?

- The typical lengths of steel angles available in the market vary depending on the specific needs and requirements of the project. However, there are some common standard lengths that are readily available. These typically range from 20 feet to 40 feet, with incremental measurements such as 20 feet, 25 feet, 30 feet, 35 feet, and 40 feet. These lengths are commonly used in construction and industrial applications where steel angles are utilized for structural support, framing, and bracing purposes. It is important to note that customized lengths can also be obtained through special orders or fabrication, allowing for more flexibility in meeting specific project requirements.

- Q: How can steel angles be protected against corrosion?

- Steel angles can be protected against corrosion through various methods. One common method is the application of protective coatings. These coatings act as a barrier between the steel angles and corrosive elements, preventing direct contact and inhibiting corrosion. Coatings such as paint, epoxy, or zinc-based materials can be used to provide this protection. Another effective method is galvanization. This process involves coating the steel angles with a layer of zinc, which acts as a sacrificial anode. When corrosion occurs, the zinc layer will corrode first, protecting the steel underneath. This is particularly effective in harsh environments, such as marine or industrial settings. Regular maintenance and inspection are essential in preventing corrosion. Any damage or deterioration to the protective coating should be promptly repaired to ensure continued protection. Furthermore, keeping the steel angles clean and free from debris or moisture buildup can also help prevent corrosion. In some cases, cathodic protection may be employed. This involves connecting the steel angles to a sacrificial anode, typically made of a more reactive metal, such as aluminum or magnesium. The anode will corrode instead of the steel angles, providing protection against corrosion. Lastly, proper design and installation of steel angles can also contribute to their corrosion resistance. Ensuring adequate drainage and ventilation, using materials compatible with the environment, and minimizing exposure to corrosive elements can all help in protecting steel angles against corrosion.

- Q: Can steel angles be galvanized or coated for additional protection?

- Indeed, steel angles can be galvanized or coated to enhance their protection. Galvanization is a widely used technique for safeguarding steel against corrosion. It entails applying a layer of zinc onto the steel, which acts as a barrier against moisture and other corrosive elements. This process can be accomplished through hot-dip galvanization, where the steel angle is immersed in a bath of molten zinc, or through electroplating, which involves applying a thin layer of zinc to the steel surface using an electric current. Furthermore, coating steel angles with alternative protective materials is a viable option. There are several coating choices available, including epoxy, powder coatings, and paint. These coatings establish a protective layer on the steel's surface, shielding it from environmental factors that may cause corrosion or damage. By applying galvanization or coatings to steel angles, additional protection is provided, thereby extending the material's lifespan and ensuring its durability in various applications and environments.

- Q: What are the different surface treatments available for steel angles?

- There are several surface treatments available for steel angles, including galvanization, painting, powder coating, and epoxy coating.

- Q: What's the chemical reaction between stainless steel and galvanized angle iron?

- They are not the two reaction, after they are Unicom, there can be electronic flow, and zinc than iron lively, so galvanized angle iron is more likely to be corrosion (mainly air oxidation).

- Q: What is the maximum allowable torsional stress for a steel angle?

- The maximum allowable torsional stress for a steel angle depends on several factors, including the specific grade of steel, the dimensions and shape of the angle, and the intended application. Steel angles are commonly used in structural applications, such as supporting beams and frames, and they are designed to withstand various types of stresses, including torsional stress. To determine the maximum allowable torsional stress for a steel angle, engineers typically refer to industry standards and codes, such as the American Institute of Steel Construction (AISC) Manual or the European standard EN 10056. These standards provide guidelines and formulas for calculating the maximum allowable torsional stress based on the properties of the steel angle, such as the cross-sectional area, moment of inertia, and modulus of elasticity. It is important to note that the maximum allowable torsional stress is usually specified as a percentage of the yield strength or ultimate tensile strength of the steel. This ensures that the angle can safely withstand torsional loads without undergoing permanent deformation or failure. In practical applications, engineers and designers must carefully analyze the specific requirements and loading conditions to determine the appropriate maximum allowable torsional stress for a steel angle. They consider factors such as the magnitude and direction of the applied torque, the angle's orientation, and any additional loads or constraints that may be present. Ultimately, the maximum allowable torsional stress for a steel angle is a critical parameter in ensuring the structural integrity and safety of a given design. Proper consideration of the steel's properties, industry standards, and specific application requirements is essential for making accurate calculations and selecting an appropriate steel angle that can effectively resist torsional stress.

- Q: Can steel angles be used in temporary or modular structures?

- Yes, steel angles can be used in temporary or modular structures. Steel angles provide structural support and stability, making them suitable for various construction applications, including temporary or modular structures. They can be easily fabricated and assembled, offering flexibility and durability required for such structures.

- Q: Can steel angles be used in historical or heritage restoration projects?

- Yes, steel angles can be used in historical or heritage restoration projects. They are commonly used in these projects for their strength, durability, and versatility. Steel angles can be shaped and customized to match the original architectural elements, making them suitable for replicating or repairing historical structures. Additionally, their corrosion resistance and ability to withstand various weather conditions make them a reliable choice for long-term preservation.

Send your message to us

Unequal Stainless Steel 304 Angle Bars or Angle Iron Steel Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords