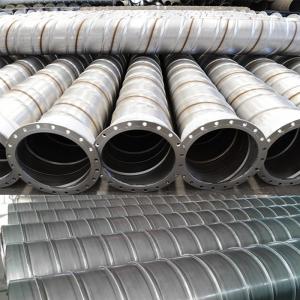

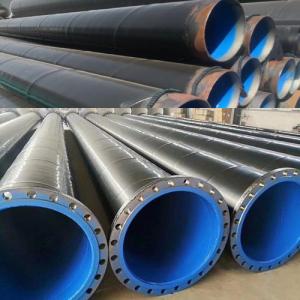

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

Press grade: Maximum PN -0.097MPa

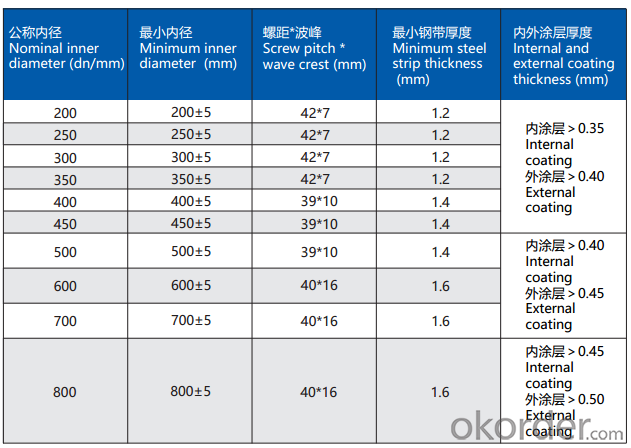

Size: DN200MM-DN800MM

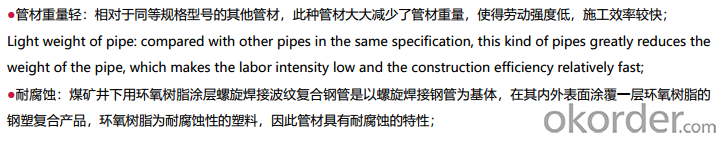

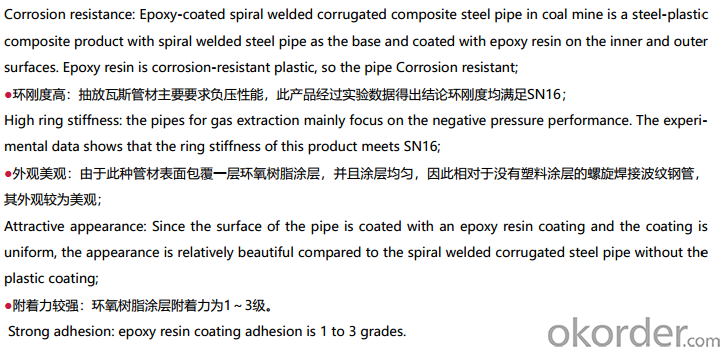

Features:

Specification

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: What are the advantages of using steel pipes over other materials?

- Using steel pipes instead of other materials has several advantages: 1. Exceptional strength and durability: Steel pipes have the ability to withstand high pressure, heavy loads, and extreme weather conditions. This makes them suitable for various uses, such as transporting fluids and gases, providing structural support, and laying underground pipelines. 2. Enhanced resistance to corrosion: Steel pipes can be coated with different materials to increase their resistance to corrosion. This makes them ideal for transporting corrosive substances like water and chemicals without the risk of pipe degradation. Additionally, steel pipes are less prone to rust, which prolongs their lifespan. 3. Long-term cost-effectiveness: Although the initial cost of steel pipes may be higher than other materials, they offer long-term cost-effectiveness. Due to their durability and resistance to corrosion, steel pipes require less maintenance and replacement, resulting in reduced operational costs over time. 4. Versatility: Steel pipes come in various sizes, shapes, and thicknesses, making them versatile for different applications. They can be easily customized and fabricated to meet specific requirements, such as bending, welding, and threading. 5. Fire resistance: Steel pipes have a high melting point, making them resistant to fire and reducing the risk of structural damage in case of a fire incident. This characteristic is particularly important in industries where fire safety is crucial, such as oil and gas, chemical, and construction. 6. Environmentally friendly: Steel is a recyclable material, and steel pipes can be recycled and reused multiple times without compromising their quality. This not only reduces the demand for new materials but also contributes to environmental sustainability. 7. Excellent flow characteristics: Steel pipes have smooth internal surfaces, minimizing friction and allowing for efficient flow of fluids and gases. This advantage is particularly significant in industries where fluid dynamics and energy efficiency are essential, such as oil and gas, water supply, and HVAC systems. In conclusion, steel pipes offer numerous advantages over other materials, including strength, durability, corrosion resistance, cost-effectiveness, versatility, fire resistance, eco-friendliness, and excellent flow characteristics. These advantages make steel pipes the preferred choice for a wide range of applications in various industries.

- Q: What is the difference between hot dip galvanized steel pipe and galvanized steel pipe?

- The difference between the process is that the hot dip galvanized pipe is dipped in the molten zinc bath and the galvanized pipe is plated with a metallic surface by means of unidirectional current in the plating bath. Hot plating process is fast, the coating is thick and consumes more zinc. Ordinary galvanized slow speed, thin coating.

- Q: How do you calculate the flow rate in a steel pipe?

- To calculate the flow rate in a steel pipe, several parameters need to be considered. The first and most important parameter is the cross-sectional area of the pipe, which can be calculated using the formula A = πr², where A is the cross-sectional area and r is the radius of the pipe. Next, the velocity of the fluid flowing through the pipe needs to be determined. This can be done using the equation v = Q/A, where v is the velocity, Q is the volumetric flow rate, and A is the cross-sectional area of the pipe. To calculate the volumetric flow rate, the equation Q = AV can be used, where Q is the volumetric flow rate, A is the cross-sectional area, and V is the average velocity of the fluid. Additionally, it is important to take into account the properties of the fluid being transported through the pipe. The density and viscosity of the fluid can affect the flow rate. Overall, the flow rate in a steel pipe can be calculated by determining the cross-sectional area of the pipe, calculating the velocity of the fluid, and considering the properties of the fluid being transported.

- Q: What are the different methods of inspecting steel pipes?

- There are several methods of inspecting steel pipes, including visual inspection, ultrasonic testing, magnetic particle testing, dye penetrant testing, radiographic testing, and eddy current testing.

- Q: What is galvanized steel pipe?

- Galvanized steel pipe is a type of steel pipe that has been coated with a layer of zinc, which helps protect it from corrosion and rust. This coating also increases the pipe's longevity and makes it suitable for various applications, including plumbing, construction, and outdoor structures.

- Q: What are the safety precautions for handling steel pipes?

- When handling steel pipes, it is important to take several safety precautions to prevent accidents and minimize the risk of injury. Here are some key safety measures to follow: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, hard hats, steel-toed boots, and gloves. This will protect you from potential hazards such as falling objects, sharp edges, or chemical spills. 2. Proper Lifting Techniques: When lifting steel pipes, use proper lifting techniques to avoid strain or back injuries. Bend your knees, keep your back straight, and lift using your legs instead of your back. If the pipe is too heavy, seek assistance or use mechanical lifting equipment. 3. Secure Storage and Stacking: Store steel pipes in a well-organized manner, ensuring they are properly stacked and secured. Use suitable storage methods, such as racks or pallets, to prevent pipes from rolling or falling. Avoid stacking pipes too high to prevent instability. 4. Inspect for Defects: Before handling steel pipes, inspect them for defects such as cracks, corrosion, or dents. Defective pipes can pose serious safety risks, so it is important to identify and remove them from use. 5. Use Appropriate Handling Equipment: When moving or transporting steel pipes, utilize appropriate equipment such as forklifts, cranes, or hoists. Ensure that the equipment is in good working condition, and always follow the manufacturer's guidelines for safe operation. 6. Secure Transportation: If transporting steel pipes by vehicle, make sure they are properly secured to prevent shifting or falling during transit. Use straps, chains, or other restraints to secure the load. 7. Watch for Sharp Edges: Steel pipes can have sharp edges that can cause cuts or injuries. Be cautious when handling them and wear gloves to protect your hands. 8. Communication and Training: Communicate with your team members to ensure everyone understands the proper handling procedures and safety precautions. Provide training on safe lifting techniques, equipment operation, and hazard identification. 9. Maintain a Clean Work Area: Keep the work area clean and free from debris, oil, or other slippery substances that could cause slips or falls. 10. Follow Safety Guidelines: Always adhere to safety guidelines and procedures established by your organization or relevant regulatory authorities. These guidelines may include additional precautions specific to your work environment. By following these safety precautions, you can significantly reduce the risk of accidents and injuries when handling steel pipes. Remember, safety should always be the top priority in any work environment.

- Q: How can galvanized steel pipe be connected with stainless steel pipe?

- Attention should be paid to the zinc coating at the side of the groove before welding. It is OK to brush silver powder after welding. There is a lot of information about the welding of carbon steel and stainless steel. Just check it online.

- Q: What are the common methods for inspecting the integrity of steel pipes?

- There are several common methods used to inspect the integrity of steel pipes. These methods are crucial to identify any defects or weaknesses in the pipes that could compromise their structural integrity and potentially lead to failures or leaks. 1. Visual Inspection: This is a basic method where an inspector visually examines the external surface of the steel pipe for any signs of damage, such as corrosion, cracks, or deformities. It is a quick and cost-effective method, but it may not detect internal defects. 2. Ultrasonic Testing (UT): UT is a non-destructive testing method that uses high-frequency sound waves to detect flaws in steel pipes. A transducer sends ultrasonic waves into the pipe, and any reflected waves are analyzed to identify defects like cracks or voids. UT is effective for both internal and external inspections and can provide accurate measurements of defect size and location. 3. Magnetic Particle Inspection (MPI): This method is mainly used to detect surface or near-surface defects in ferromagnetic materials like steel. Magnetic particles are applied to the surface of the pipe, and if there is a defect, the particles will gather around it, creating a visible indication. MPI is particularly useful for detecting cracks and other discontinuities that may not be easily visible to the naked eye. 4. Radiographic Testing (RT): RT involves the use of X-rays or gamma rays to inspect the internal structure of steel pipes. The rays pass through the material, and a radiographic film or a digital detector records the image. This method is effective in detecting internal defects such as cracks, voids, or inclusions. However, it requires proper safety precautions due to the use of radiation. 5. Eddy Current Testing (ECT): ECT is a non-destructive testing method that uses electromagnetic induction to assess the integrity of steel pipes. An alternating current is passed through a probe, creating an electromagnetic field. Any changes in the electrical conductivity or magnetic permeability of the material due to defects are detected by the probe, providing information about the pipe's condition. These are some of the common methods used for inspecting the integrity of steel pipes. Each method has its advantages and limitations, and the choice of inspection method depends on factors such as the type of defect to be detected, access to the pipe, and budget constraints. Regular inspection and maintenance using these methods are crucial to ensure the safe and reliable operation of steel pipe systems.

- Q: What are the safety precautions when working with steel pipes?

- When working with steel pipes, some important safety precautions to follow include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Additionally, it is essential to ensure proper ventilation in the work area to prevent the accumulation of hazardous fumes or gases. Using the correct tools and equipment, such as pipe wrenches and clamps, and following proper lifting techniques are crucial to avoid strains or back injuries. Regular inspection and maintenance of the pipes and equipment are also necessary to prevent any potential accidents. Lastly, it is important to receive proper training and follow established safety procedures to minimize risks and promote a safe working environment.

- Q: Are steel pipes resistant to impact or external forces?

- Yes, steel pipes are generally resistant to impact or external forces due to their inherent strength and durability. They can withstand high pressure, heavy loads, and harsh environmental conditions, making them suitable for various applications, including construction, transportation, and industrial purposes.

Send your message to us

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords