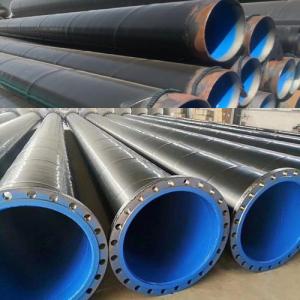

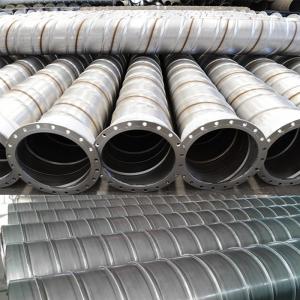

Spiral Welded Plastic-coated Epoxy Resin Steel Pipe with Reinforcement Bar for Coal Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Spiral Welded Plastic-coated Epoxy Resin Steel Pipe with Reinforcement Bar for Coal Mining

Press grade: Maximum PN -0.097MPa

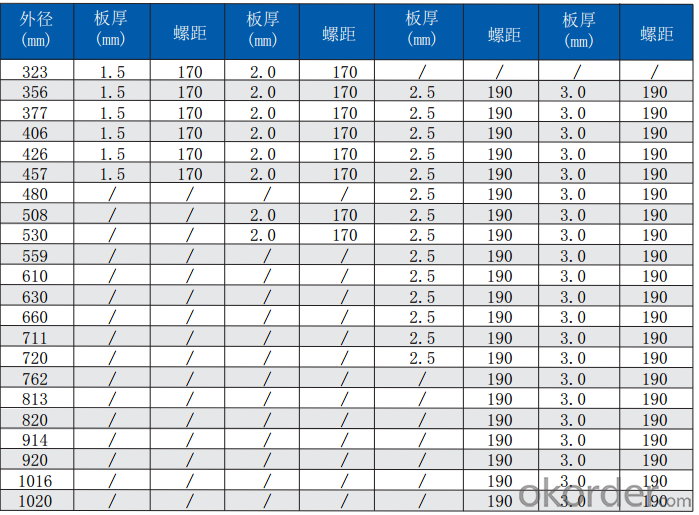

Size: DN300MM-DN1000MM

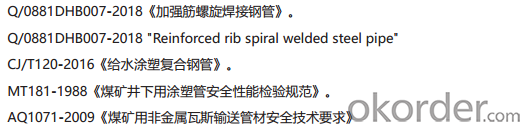

Standards:

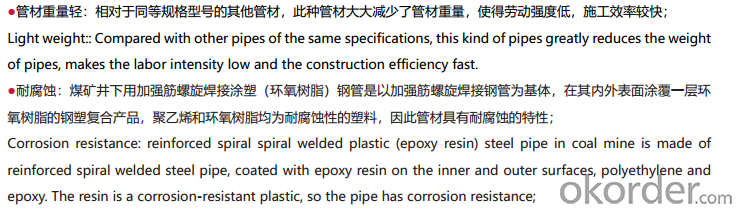

Features:

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Who knows what is the difference between double submerged arc welded pipe and longitudinal submerged arc welding?

- Double submerged arc welding should be for spot welding and single side welding, they are straight line welds, but double submerged arc welding seam is more beautiful and fine.

- Q: What does "HBB" glass steel pipe mean?

- Good water resistance, can be used for a long time in wet or water, and the ordinary composite is not water resistant, can only be used in dry environment.Heat resistance, fire resistance is superior to epoxy, glass fiber reinforced plastics and plastic and other materials. It can be used at 130 degrees for a long time, and not burned in case of fire.The utility model has the advantages of insulation, corrosion prevention, no rust, long service life, etc.. Generally up to 50 years, without maintenance.Simple and convenient installation and construction, because this product is light weight, high strength, laying construction method can properly solve the excavation due to road construction, exposed for a long time, prominent problems of city traffic, to achieve the excavation backfill pavement, buried at night, can normal traffic during the day.

- Q: What is the difference between hot-rolled and cold-rolled steel pipes?

- The main difference between hot-rolled and cold-rolled steel pipes lies in the manufacturing process. Hot-rolled steel pipes are produced at high temperatures, which results in a rougher surface and less precise dimensions. On the other hand, cold-rolled steel pipes are manufactured at lower temperatures, leading to a smoother surface finish and more accurate measurements. Additionally, the hot-rolling process allows for a wider range of steel grades and sizes, while cold-rolled pipes are generally limited in terms of thickness and diameter.

- Q: What is the difference between steel pipe and PVC pipe?

- Steel pipe and PVC pipe are both commonly used materials for plumbing and other construction applications, but they have several key differences. Firstly, the material itself is different. Steel pipe is made from steel, which is an alloy of iron and carbon. It is known for its strength and durability, making it suitable for high-pressure applications and underground installations. On the other hand, PVC (polyvinyl chloride) pipe is made from a type of plastic known as PVC. It is lightweight, flexible, and easy to handle, making it a popular choice for residential plumbing and irrigation systems. Secondly, the installation process differs. Steel pipe requires skilled labor and specialized tools for cutting, threading, and welding. It often involves a complex installation process, especially for larger pipe sizes. PVC pipe, on the other hand, can be easily cut with a saw or specialized pipe cutter and joined together using solvent cement or threaded fittings. This makes PVC pipe more suitable for do-it-yourself projects and simpler installations. Thirdly, steel pipe has a higher cost compared to PVC pipe. Steel is a more expensive material, and the manufacturing process for steel pipe is more complex, involving multiple steps and additional materials. PVC pipe, being made from plastic, is generally cheaper and more cost-effective, especially for smaller diameter applications. In terms of performance, steel pipe has higher tensile strength, can withstand higher pressure, and is more resistant to temperature changes, making it ideal for heavy-duty and industrial applications. PVC pipe, on the other hand, has a lower tensile strength but is resistant to corrosion, chemicals, and scale buildup. It is commonly used in residential plumbing, irrigation systems, and other non-industrial applications. In summary, the main differences between steel pipe and PVC pipe lie in the material, installation process, cost, and performance characteristics. While steel pipe is stronger and more suitable for heavy-duty applications, PVC pipe is lighter, easier to install, and more cost-effective for residential and non-industrial uses.

- Q: Are steel pipes affected by magnetic fields?

- Yes, steel pipes can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized and influenced by magnetic fields.

- Q: How are steel pipes used in fire protection systems?

- Steel pipes are commonly used in fire protection systems because of their durability and resistance to high temperatures. They are used to transport water or other fire suppressants to sprinkler heads or fire hydrants, ensuring quick and efficient extinguishing of fires. The strength of steel pipes also allows them to withstand the pressure and force of water flow, making them a reliable choice for fire protection systems.

- Q: What are the different types of steel pipe reducers?

- Various industrial applications commonly use different types of steel pipe reducers. These reducers facilitate the connection between pipes of varying sizes, ensuring a smooth transition in fluid or gas flow. The following are some of the most frequently encountered types: 1. Concentric Reducers: These reducers possess a symmetrical design with a centerline that aligns with both the larger and smaller pipes' centerlines. They facilitate a gradual reduction in pipe size, ensuring a seamless material flow. 2. Eccentric Reducers: In contrast to concentric reducers, eccentric reducers have an offset centerline. This design is beneficial in preventing the accumulation of air or gases in the piping system. The eccentric reducer directs any gas or air towards a vent or drain point. 3. Welded Reducers: These reducers are created through the welding of two pipes of different sizes. They are frequently used in situations that require a permanent connection. 4. Seamless Reducers: Seamless reducers are manufactured without any welded joints. They are crafted from a single piece of steel, enhancing their strength and durability. Seamless reducers are often preferred in applications where leak-proof connections are crucial, such as high-pressure or high-temperature environments. 5. Threaded Reducers: These reducers have male and female threads on both ends, allowing for easy installation and removal. They are commonly used in low-pressure applications and are a cost-effective option for systems that require frequent disassembly. 6. Flanged Reducers: Flanged reducers possess flanges on both ends, which are bolted together to create a secure seal. They are frequently used in piping systems that require convenient access for maintenance or inspection. Each type of steel pipe reducer offers its own unique advantages and is selected based on the specific requirements of the application. Factors such as the transported fluid or gas type, pressure and temperature conditions, and the need for easy installation or maintenance should be considered when choosing the appropriate reducer for a particular system.

- Q: What are the different methods of insulation for steel pipes?

- There are several methods of insulating steel pipes, including applying a thermal insulation coating, using pipe wraps or jackets, using foam insulation, or utilizing heat shrink sleeves.

- Q: What is the role of steel pipes in HVAC systems?

- Steel pipes play a crucial role in HVAC systems as they are used to transport hot or cold water, steam, and refrigerant gases throughout the system. They provide a durable and reliable conduit for the flow of fluids, ensuring efficient heating, cooling, and ventilation in buildings. Additionally, steel pipes are resistant to corrosion and can withstand high pressure, making them ideal for HVAC applications.

- Q: What are the environmental impacts of using steel pipes?

- The environmental impacts of using steel pipes include the extraction and processing of raw materials, energy consumption during manufacturing, and carbon emissions. Additionally, the disposal of steel pipes can contribute to landfill waste. However, steel pipes are highly durable, recyclable, and have a long lifespan, which mitigates some of these negative impacts.

Send your message to us

Spiral Welded Plastic-coated Epoxy Resin Steel Pipe with Reinforcement Bar for Coal Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords