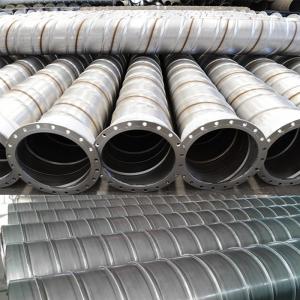

Underground Rib Reinforced Spiral Welded Galvanized Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Rib Reinforced Spiral Welded Stainless Steel Pipe for Mining

Press grade: Maximum PN -0.097MPa

Size: DN300MM-DN1000MM

Standards:

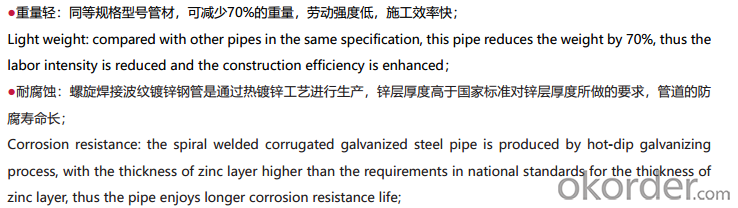

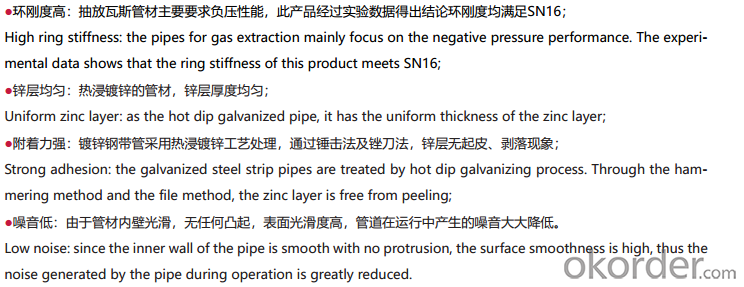

Features:

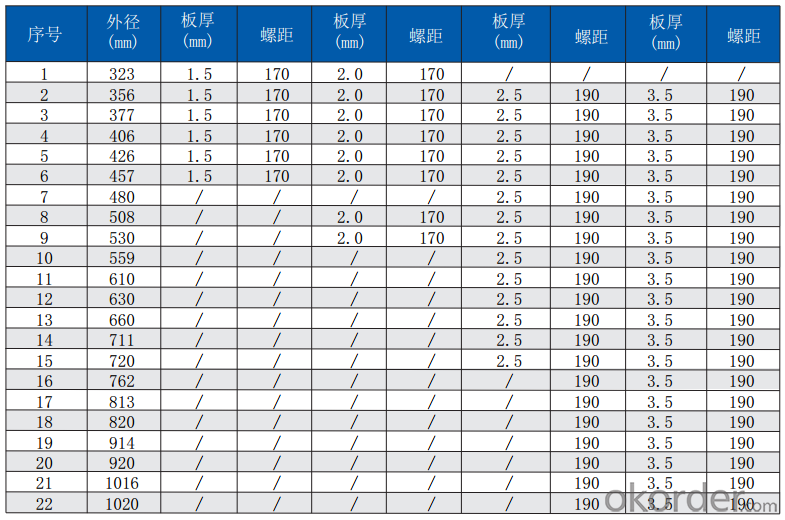

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Can steel pipes be used for airport construction?

- Yes, steel pipes can be used for airport construction. Steel pipes are commonly used in various applications in the construction industry, including airports. They are often used for underground utilities such as water and sewage lines, as well as for structural purposes such as supporting the airport terminal building. Steel pipes offer several advantages for airport construction. Firstly, they have high strength and durability, making them suitable for handling heavy loads and withstanding adverse weather conditions. This is important for ensuring the safety and stability of airport structures. Secondly, steel pipes are versatile and can be easily customized to fit specific project requirements. They come in various sizes and thicknesses, allowing for flexibility in design and construction. Additionally, steel pipes can be welded or joined together to create longer sections, which simplifies installation and reduces construction time. Moreover, steel pipes are resistant to corrosion, which is crucial in airports where there is constant exposure to moisture, salt, and other environmental factors. Their resistance to corrosion ensures the longevity and reliability of the infrastructure. Lastly, steel pipes are cost-effective compared to other materials such as concrete or PVC. They have a relatively low maintenance requirement and a long lifespan, reducing the need for frequent repairs or replacements, thus saving time and money in the long run. In conclusion, steel pipes are a suitable choice for airport construction due to their strength, durability, versatility, corrosion resistance, and cost-effectiveness.

- Q: What are the different types of steel pipe caps?

- There exists a variety of steel pipe caps, each serving specific purposes and applications. A few commonly used types are as follows: 1. Threaded Caps: These caps possess internal threads that enable them to be screwed onto threaded pipes, ensuring a secure seal. They find frequent usage in plumbing and gas-related tasks. 2. Socket Weld Caps: These caps are designed for welding onto pipe ends using a socket weld connection. They offer a strong and permanent seal, rendering them suitable for high-pressure and high-temperature tasks. 3. Butt Weld Caps: Butt weld caps, similar to socket weld caps, are meant for welding onto pipe ends. However, they are specifically designed for butt welding, which involves directly welding the cap to the pipe without additional fittings. 4. Domed Caps: These caps have a domed or rounded shape on the upper surface, providing a smooth and visually pleasing finish. They are commonly applied in architectural and decorative tasks, such as handrails or fence posts. 5. Flat Caps: As the name suggests, flat caps possess a flat upper surface. They are often utilized when a simple and low-profile cap is required, such as for safeguarding pipe ends in industrial applications. 6. Blind Caps: Blind caps are employed to permanently seal off pipe ends. They are solid caps without any openings or threads, ensuring complete closure. They are frequently utilized in piping systems where a section of the pipeline is not in use or temporarily needs to be closed off. These examples merely scratch the surface of the various steel pipe caps available. The selection of a cap depends on specific application requirements, including the type of connection, pressure, temperature, and the necessity for structural or decorative finishes. It is crucial to choose the appropriate cap to guarantee a secure and reliable seal for the pipe.

- Q: What are the different strategies for pipe laying using steel pipes?

- There are several strategies for pipe laying using steel pipes, including open cut trenching, trenchless methods such as horizontal directional drilling (HDD), microtunneling, and pipe jacking. In open cut trenching, a trench is dug and the steel pipes are laid in the trench before it is backfilled. HDD involves drilling a small pilot hole underground and then pulling the steel pipes through the hole. Microtunneling uses a remote-controlled boring machine to excavate a tunnel and install the steel pipes simultaneously. Pipe jacking involves pushing the steel pipes into the ground using hydraulic jacks while excavating the soil in front of the pipes. Each strategy has its advantages depending on the specific project requirements and conditions.

- Q: Can steel pipes be used for transporting hazardous materials?

- Yes, steel pipes can be used for transporting hazardous materials. Steel is known for its strength and durability, making it suitable for handling and containing hazardous substances. It is commonly used in various industries, such as oil and gas, chemical, and wastewater treatment, to transport materials that pose a potential risk to human health or the environment. Additionally, steel pipes can resist corrosion and high pressure, ensuring the safe transportation of hazardous materials.

- Q: How do steel pipes handle vibrations?

- The effectiveness of handling vibrations is a well-known attribute of steel pipes. Their strong and rigid nature enables them to withstand various types of vibrations, including mechanical vibrations and seismic activities. The structural integrity and strength of steel pipes are responsible for their resilience. Steel pipes possess high tensile strength, which allows them to resist deformation or breakage when exposed to vibrations. They also exhibit resistance to fatigue, meaning they can endure repeated vibrations without suffering significant damage. This quality makes steel pipes ideal for applications involving constant or cyclic vibrations, such as in industrial settings or for fluid transportation through pipelines. Furthermore, steel pipes have the added advantage of being able to dampen vibrations due to their mass. The weight of the steel pipe aids in absorbing and dissipating the energy generated by vibrations, preventing excessive movement or oscillation. This damping effect contributes to the overall stability and durability of the pipe system. Various measures can be taken to further enhance the ability of steel pipes to handle vibrations. These measures may include the utilization of vibration isolators or dampers, which are devices designed to reduce the transmission of vibrations from the surrounding environment. Additionally, proper installation techniques and regular maintenance can help ensure that steel pipes continue to function optimally under conditions prone to vibrations. In conclusion, steel pipes possess the necessary attributes to effectively handle vibrations, including strength, resistance to fatigue, and the ability to dampen vibrations. Their robustness and durability make them a reliable choice for applications where vibrations are a concern, guaranteeing the safe and efficient transportation of fluids or materials.

- Q: How are steel pipes used in the manufacturing of food processing machinery and equipment?

- Steel pipes are an essential component in the manufacturing of food processing machinery and equipment due to their numerous advantageous properties. These pipes are widely used in the food industry for their durability, corrosion resistance, and ability to withstand high temperatures and pressures. One of the primary applications of steel pipes in food processing machinery is for the transportation of various fluids and gases. These pipes are used to carry water, steam, and other liquids, as well as air and gases, throughout the processing plant. Steel pipes provide a reliable and hygienic means of transferring these substances, ensuring that the quality and safety of the food products are maintained. Moreover, steel pipes are also utilized in the design and construction of food processing equipment such as mixers, blenders, conveyors, and canning machines. These machines often require the use of pipes to facilitate the movement of ingredients, processing fluids, and cleaning agents. Steel pipes are an ideal choice for these applications due to their high strength, which allows them to handle the heavy loads and pressures associated with food processing operations. Another crucial aspect of steel pipes in food processing machinery is their resistance to corrosion. Food processing involves the use of various acidic and alkaline substances, as well as hot water and steam, which can cause corrosion in other materials. Steel pipes, particularly those made from stainless steel, are highly resistant to corrosion, ensuring that the machinery remains in optimal condition and prolonging its lifespan. Furthermore, the smooth internal surface of steel pipes allows for efficient and hygienic cleaning, as it minimizes the accumulation of food particles and contaminants. This is of utmost importance in the food industry, where maintaining high levels of cleanliness is essential to prevent the growth of bacteria and ensure food safety. In summary, steel pipes play a crucial role in the manufacturing of food processing machinery and equipment. Their durability, corrosion resistance, ability to handle high temperatures and pressures, and hygienic characteristics make them an ideal choice for the transportation of fluids and gases, as well as for the construction of various food processing equipment.

- Q: How are steel pipes protected against seismic activities?

- Steel pipes are protected against seismic activities through various measures such as designing them to be flexible and resilient, using seismic joints and hangers, and implementing proper anchoring and support systems. Additionally, steel pipes are often coated with protective materials to enhance their resistance to corrosion and other external factors that may be triggered by seismic events.

- Q: What are the factors affecting the durability of steel pipes?

- There are several factors that can affect the durability of steel pipes. These include corrosion, temperature fluctuations, mechanical stress, and exposure to chemicals or abrasive materials. Additionally, the quality of the steel used in the pipes, the design and construction of the piping system, and proper maintenance and inspection practices can also impact their durability.

- Q: How do you calculate the pipe flow velocity for steel pipes?

- To calculate the pipe flow velocity for steel pipes, you can use the Manning's formula or the Darcy-Weisbach equation. 1. Manning's formula: This formula is commonly used for open channel flow but can also be applied to partially filled pipes. It calculates the velocity based on the pipe's hydraulic radius, slope, and Manning's roughness coefficient. The formula is as follows: Velocity (V) = (1.486/n) * (R^2/3) * (S^1/2) Where: - V is the velocity - n is the Manning's roughness coefficient (which can be obtained from reference tables) - R is the hydraulic radius (cross-sectional area divided by wetted perimeter) - S is the slope of the energy grade line 2. Darcy-Weisbach equation: This equation is widely used for pipe flow calculations and is based on the principle of energy conservation. It calculates the velocity based on the pipe's diameter, roughness coefficient, and the head loss due to friction. The formula is as follows: Velocity (V) = (2 * g * hL)^0.5 Where: - V is the velocity - g is the acceleration due to gravity (approximately 9.81 m/s^2) - hL is the head loss due to friction, which can be calculated using the Darcy-Weisbach equation: hL = (f * L * V^2) / (2 * g * D) Where: - f is the Darcy friction factor (which depends on the Reynolds number and pipe roughness) - L is the length of the pipe - D is the diameter of the pipe Both formulas require some input parameters such as pipe dimensions, roughness coefficients, and slope. These parameters can be obtained from engineering references or pipe manufacturer specifications. It is important to note that these formulas provide approximate values and may require iterations or adjustments for accurate results.

- Q: What are low-pressure carbon steel tubes?

- Pipe fittingsA pipe fitting is a piece of pipe that is connected to a pipe. According to the connection method can be divided into socket type pipe fittings, threaded fittings, flange fittings and welding pipe four categories. Multipurpose; made of the same material as pipes. Elbow (elbow), flange, three pipe and four pipe (crosshead) and reducer (reducer) etc.. Elbow for pipeline corner; flange for the pipe and pipe interconnected parts, connected to the pipe end, three pipe for three pipe collection; four pipe for four tubes together place; for two pipes of different diameters connected to different diameter pipe.

Send your message to us

Underground Rib Reinforced Spiral Welded Galvanized Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords