Tower Crane of Jing Kui Model Number QTZ56(5009)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

QTZ56(5009) Description

Feature: Tower Crane

Condition: New

Rated Loading Capacity: 4

Rated Lifting Moment: 500

Max. Lifting Load: 4

Max. Lifting Height: 121

Span: 50

Place of Origin: Shandong, China (Mainland)

Brand Name: JINKUI

Model Number: QTZ56(5009)

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Certification: ISO9001:2000; CE;Ukraine & Belarus Certificate

Colour: Orange/ Yellow

QTZ56(5009) Features

1.Thirteen years of experience in supplying new self-erecting tower crane with Huiyou Brand.

2. Export to more than 20 countries with CE/ISO/GOST Certificates.

3. Stationary/Travelling, external/ internal climbing tower crane

4. Impeller blasting/rust protection paint

5. Advanced painting process

6. Potain masts designed with dismountable panels, making teansport easier and cheaper.

7. New designed mast, can be used to Internal and external climbing tower crane

8. Famous brand mechanism system, Schneider Electronic control system, jiangte and jiuhe motor

9. Engineers available to service machinery overseas.

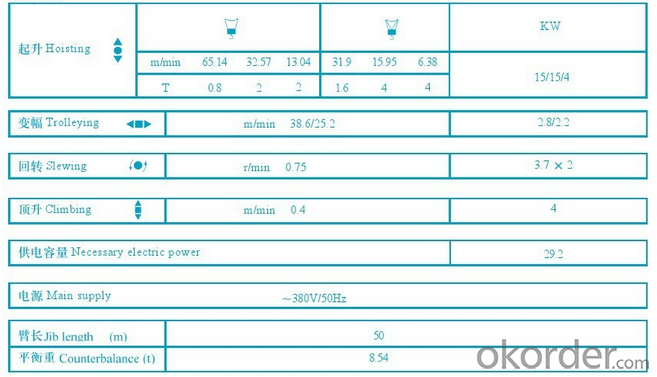

QTZ56(5009) Specification

QTZ56(5009) Pictures

QTZ56(5009) FAQ

Q: What kind of steel used for tower crane?

A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients’ requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

Q: What is the function of the monitor?

A: Monitor, namely inspection system (like black box), which could store 10000 tower crane operation reports, and it is recommended to be installed in big cranes more than 16t.

- Q: There is no CAD map attached to embedded parts of tower crane?

- Where there are special drawings, we are using the embedded parts of tower crane attachment reinforced pre buried above 32mm (with hook) in concrete beam column, with the head of the thread and attached connection

- Q: What is the difference between a jack up tower crane and a fixed tower crane?

- The fixed tower crane means lifting the foundation of the tower body on the foundation or structure through the connecting piece.

- Q: A. to make everyone become a CommunistB. to become rich at the expense of othersC. to kill all the villagersD. nothing in particular

- The main idea of Cranes by Hwang Sun-Won is more of a symbolic thing; he uses different objects such as chestnuts and cigarettes, as well as the cranes in the story to convey his hope and his dream, along with his message. He is expressing the power of war, particularly civil war, which can rip apart families, neighbors and the best of friends. The story, unlike many other tragic civil war tales, is not focused on the idealogical difference btw Tok-Chae and Song-Sam. Rather, it is about the human tragedy of the Korean War. Tok-Chae and Song-Sam were ripped apart by the War. Song-Sam, on his return to his village, he finds Tok-Chae and decides to escort him to a Public Peace Police office a few miles away. On the way, he gets flashbacks and talks with Tok-Chae. These things help to change his mind and he frees Tok-Chae. This is symbolized by the two cranes which soared high into the sky. Hwang-Sun Won conveys his message effectively; unification will be achieved and is needed to repair such ties like Tok-Chae and Song-Sam. He is saying that the two cranes will fly together once more.

- Q: In the private training session, Katniss Everdeen creates a noose, hangs a practice dummy, and uses the paint to write: Seneca Crane. I know this name is mentioned earlier in the book, but I don't remember who Seneca Crane is... Remind me, please?

- Seneca Crane is the previous Gamemaker who decided to allow Peeta and Katniss to live after the berry incident. The Capitol killed her and replaced her for that act of mercy. That's why Katniss hung her; she was rebelling against the Capitol and implying that they murdered Seneca Crane.

- Q: the numbers i found on it are ay7648 ssh-310-nc

- Crane SSH-310-NC, hydraulic, rough idle, good midrange hp Intake Open-Close BTDC-ABDC 40-90 Exhaust Open-Close BBDC-ATDC 88-42 Degrees Advertised Duration Int. 310 Exh. 310 Degrees Duration @ .050 Cam Lift Int. 236 Exh. 236 Running Clearance Hot Int .000 Exh. .000 Gross Valve Lift Int. .485 Exh. .485 RPM Range min 3800 max 6800 valve float 7000

- Q: Do cranes play major role in Japanese culture? How so? Do cranes live in Japan?

- They certainly do in the Chinese culture, but I don't know anything about the Japanese. There is a very famous tower in China called the Yellow Crane, it is probably on line.

- Q: from the legend of sleepy hollow, his background, characater, personality, life etc.

- You already seem to know the answer. That's what he did. He was a detective and had his own instruments and methods for solving a crime and he was out to prove they worked in Sleepy Hollow.

- Q: I was watching Batman Begins and at the end Gorden says that he hasn't caught Crane. Since the villians in the next Batman movie are going to be two-face and the joker will Crane make a reapperance in the thrid movie (if there is one)?

- The Joker became employed by making use of the particularly some crime businesses to kill the Batman. He used his criminal genius to concoct an tricky plan to stress Batman to bare his identity. this could harm Batman's benefit of anonymity, making it much less complicated to kill him. because it became out, The Joker didn't wish money, he wanted to run Gotham city's criminal underground, Batman and Harvey Dent have been interior the way. interior the Batman comics, the Joker is Batman's arch enemy. Homicidal, and outstanding, he's often finding for a thank you to kill Batman. regardless of if it skill killing innocents or destroying Gotham city interior the technique. For all those at a loss for words approximately Joker robbing banks: He merely robbed the banks that the criminals had their money in. by making use of doing this, he became particular to get their interest. while Gordon and his team cracked down on 'the mobs'' materials, Joker became there to lend guidance by making use of removing all those that have been inflicting the subject concerns. especially Harvey Dent, and Batman, yet in addition the Commissioner, and the decide allowing Dent to prosecute them. continuously a pair of steps previous to maximum, he knew by making use of soliciting for 0.5 of 'the mob's' money, they had be vulnerable sufficient to overhaul. the explanation Batman completes Joker is as a results of the fact Batman is the only guy or woman clever sufficient to make certain by using his plans. for this reason, it quite is mostly a project to defeat Batman, yet not inevitably kill him.

- Q: because i have this huge sofa i need to get to 2nd floor but i cant coz the staircase is too small

- Talk to a lumber yard that has a boom truck. Ask them how much to do it. A boom truck will cost much less than a crane. A boom truck can reach 45 to 50 feet. In this economy they are looking for anything they can get. They will most likely do it. But when really busy they wont. But things are slow. Builder 30 years. A crane will cost about 250.00 of the first hour. with a one hour min.

- Q: A crew built this huge crane to build an office building next to my house.... There is a huge flag hanging from the top of it.... Why does the construction company do this???

- Crane Flags

Send your message to us

Tower Crane of Jing Kui Model Number QTZ56(5009)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords