Toptile Fiberglass Ceiling Tiles - Stick-On Acoustic Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

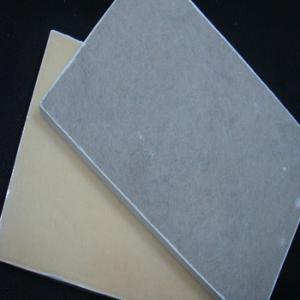

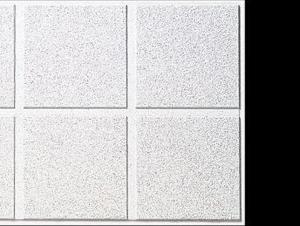

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

Images:

- Q: Old house would like to decorate their own what good material?

- First get the wall look ah, ah big white powder or paste wallpaper. And then get a video wall. The ground re-leveling, shop a floor. The door or about a door or a door frame. In short, according to their own preferences, the house dress up. Such as the use of Dulux environmental paint to paint the wall into other colors, refreshing thing. The toilet can be decorated with very style mosaic.

- Q: My basement is unfinished and gets VERY cold. The cieling in the basement is completely unfinished, i can see the beams and floor boards of the first floor. Can i assume this will cause the upstairs to get cold much faster and to lose alot of its heat?if so, what are my options for insulating the ceiling? i dont have alot of money, and its a rental home so the investment isnt worth it for me if it is a major expense

- heat rises, cool air sinks so heat leaking from the upstairs to the basement is unlikely. Drafts are a different story if your house is not tight. Look into an acoustic drop ceiling, if you can create a dead zone of air between basement and upstairs this will insulate.

- Q: I bought a new house is the top floor, not submitted to find the top (rooftop) on the cracks, I would like to ask such a house qualified? Will it be leaking later?

- See this kind of construction quality, can not guarantee will not leak, you should take the photo is the second layer of 40 thick stone concrete, you should ask developers to do water test, 24 hours after the ceiling no water, generally rain does not Will leak.

- Q: Do the glass fiber composite material be bad for the human body?

- Centrifugal glass wool internal fiber fluffy staggered, there are a large number of tiny pores, is a typical porous sound-absorbing material, with good sound absorption characteristics. Centrifugal glass wool can be made of wall panels, ceilings, space sound absorbers, etc., can absorb a lot of room sound energy, reduce reverberation time, reduce indoor noise.

- Q: Interior designers should understand which decoration materials

- If you want to be the basic designer to all materials should be familiar with, some not commonly used materials are not too familiar with the words also have a better understanding.

- Q: How to do a good job on the wall when the level of leveling work

- 1. Check the ground humidity, confirm the ground dry; check the ground flatness, confirm the ground level; check the ground hardness, the ground should be no cracks. 2. Thoroughly clean the ground, remove all kinds of dirt on the ground, such as paint, oil and paint and so on. Fully polished the ground. 3. completely suck the dust. 4. The interface agent with a foam roller coating, 1: 1 watered, the amount per square meter is about 100-150 grams. 5. After the application of the interface agent, wait for 1-3 hours to maintain good ventilation, so that it is completely dry. And then self-leveling construction. 6. If it is a commercial self-leveling cement (25 kg) a bag should be poured into a 6 kg of clean water in the mixing bucket, if it is super self-leveling (25 kg) a pack should be poured into 6.5 kg of clean water Stir the barrel, with a pulp drill to stir until the formation of uniform flow of the mixture. Must ensure that no caking. And then quickly mix the mixture into the construction area, with a rake will be uniform gravity cloth, and roll with a roller, the air release. Pay attention to the reasonable arrangements for the construction staff to ensure that within 15 minutes will be a good mix of a pack of self-leveling cement construction. Complete 2 mm thick, each pack can be coated about 8 square meters. 7. After about 24 hours, self-leveling cement is completely dry, 1-2 days after the floor laying. Note: Ground temperature below 5 degrees can not be self-leveling cement construction. The above-mentioned drying time is applied at room temperature of 20 ° C under normal conditions. This drying time will be extended due to low temperature and high humidity.

- Q: I am doing some minor remodeling on a house. I wanted texture on the walls but didn't want to deal with the mess (and expertise required) of spray texture, so I'm creating a custom texture on the walls by hand using lite joint compound and a 12&quot; taping knife. My question is: what do I do on the ceilings? Can I do the same thing on the walls, or will I kill my back (especially if it needs sanding). I've heard of people wrapping a small piece of plywood in plastic and using it to apply joint compound to the ceiling such that it creates little stalactites that you knock down after they have hardened slightly. That sounds difficult to get uniform across the entire ceiling.What should I do?

- i would say look it up on a website maybe HGTV

- Q: General construction industry, building materials which, how classification? What

- Paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint Diluent, Glue, Sealant, White Glue, Double Glue, 107 Glue, Wallpaper Powder, Anti-Sealing Adhesive, Plastic Floor Adhesive, Adhesive Other, Glossy Wax, Car Wax, Polishing Paint, Talc , Polished copper oil, grinding sand, alumina, roller brush, row brush, wool brush, glass fiber cloth, floor paint, putty powder, talcum powder

- Q: My studio apartment doesn't have an attic. A lot of the installation videos and articles I read online are about installing foil insulation a couple inches below the roof and above the room's ceiling. Does it matter if I install it under the ceiling (that is, the foil barrier is visible to me when inside the apartment)?Aesthetics isn't an issue. I don't mind seeing the foil. I just want to know if I can still achieve the same results whether or not I install above the ceiling. Thanks!

- If I were you I would go with 4X8 half inch foam insulation sheets from home depot. 12 bucks each and a snap to put up. You might even want to double them.

- Q: What are the active lime use?

- First, the preparation of lime mortar and lime milk coating Lime mortar from lime paste and sand, water mixed together, can be used as the wall, the ceiling of the plaster. Lime milk is made from lime cream and is often used as a paint for interior and ceiling. Second, the preparation of lime and triad soil Lime: lime + clay. Triad: lime + clay + sand, stone or slag and other fillers. Can be widely used as the basis of the building, the road or the ground cushion. Third, the production of carbonized lime board The calcined lime board is a lightweight sheet made of ground lime, fibrous filler (such as glass fiber) or lightweight aggregate (such as slag), and then made by artificial carbonization. It is suitable for non-load bearing inner wall panel , Ceiling and so on. Fourth, the production of silicate products Grinding of lime or lime powder and sand or granulated blast furnace slag, slag, fly ash and other siliceous materials by ingredients, mixing, molding, and then pressure or high pressure steam curing, can be made of dense or porous silicate products The Such as lime sand bricks, fly ash bricks and blocks, aerated concrete blocks and so on. Fifth, the preparation of clinker-free cement Will have a certain activity of the material (such as granulated blast furnace slag, fly ash, coal gangue ash and other industrial waste), according to the appropriate proportion of lime with the common grinding, can be obtained with hydraulic cementing material, that is No clinker cement.

Send your message to us

Toptile Fiberglass Ceiling Tiles - Stick-On Acoustic Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords