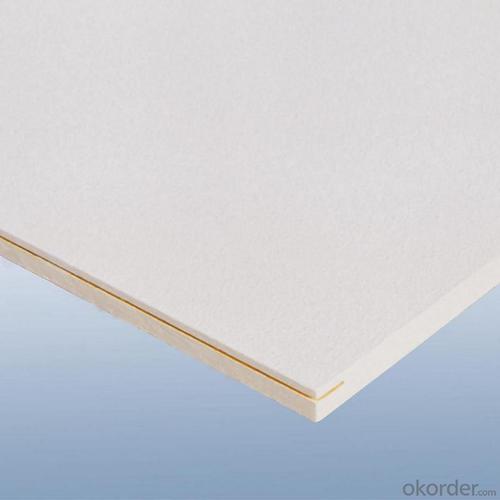

Ceiling Tiles 2x4 Fiberglass Ceiling Materials

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 3500 M2 per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Standard Size: 595mm*595mm, 605mm*605mm…

Standard Thickness: 15, 20, 25, 30, 40, 50mm…

Edge Detail: Square, Tegular, Concealed

Textures: White Painted, Mix Acoustic, White Spray, Black Spray

Technical Data of Fiberglass Ceiling:

Material: High density dry felt resin bonded fiberglass wool

Facing: Special painting laminated with decorative fiberglass tissue

Fire-resistant: Class A, non-combustible according to BS476 Part 6&7 tested overseas

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Offices, schools, libraries, hotels, cinemas, theaters, etc., where have special request for sound aborption

- Q: My basement is unfinished and gets VERY cold. The cieling in the basement is completely unfinished, i can see the beams and floor boards of the first floor. Can i assume this will cause the upstairs to get cold much faster and to lose alot of its heat?if so, what are my options for insulating the ceiling? i dont have alot of money, and its a rental home so the investment isnt worth it for me if it is a major expense

- yes the cold from the downstairs will effect the heat on first floor,all new homes come with the floor insulated,dont listen to people that dont know what they are talking about.

- Q: I kinda left the sink on while i was taking a shower.. so when i got out my bathroom floor had water everywhere (about an inch of water)i mopped up the mess with towels but i forgot to wipe inside the cabinets (and that what caused the water to soak through according to my mom) now i'm being screamed at every. single. day.on the first floor if you look up, the ceiling pretty much dried up but theres 2 creases popping out. kind of like a loong 3-d v shape since the water soaked through and outlined the cabinets shape.and since my mom loves burdening me soo much, now my parents say that they lost 5 grand in our house's value T____Ti don't know if we're supposed to repair it, paint over it (though u can't rlly paint over it), or w/e.. does anyone know what i should do? don't tell me to call a repair man because my parents want to see their 'options' before they call themThanks.. :)

- also go to youtube and look up patching ceiling and walls will help with seeing someone else do it.

- Q: Due to circumstances too complicated to go into, my husband and I ended up trying to finish the drywall on our kitchen ceiling ourselves. We were in a bind and couldn't get a contractor, so we used compound, taped, sanded, primed and painted the ceiling 2 weeks ago. In some places the tape has bubbled, in others it's clearly visable under the tape, the ceiling looks, well, bad.My question is: how best to fix it? Do we sand down to the original tape (please, nononono!) and redo it? Is there a textured paint we could use? Pressed tin panels (country house)? We don't have a lot to spend on the project, so any advice would be appreciated! (Yes, I know we messed-up when we painted)

- The specific problem areas. Replace fresh tape with mudding. When done & dry, prime paint those areas. Get bucket of sand texture and a 'bumpy' roller. Mix the texture with water until it is paintable thickness. Roll it on; it will splatter. Water & rag will wipe it off. Dry. Repaint.

- Q: It is best not to affect the decoration, the project is small, but can not be long-term to the downstairs leaking, the cause of the water may be the original decoration is not good, the last time to replace the angle valve to solve, but hope that the future no longer encounter water leakage. Do not drip, just seepage to the ceiling of the downstairs, self-house cabinets near the base line of the external paint is also mottled, downstairs ceiling also paint mottled (the room other walls or ceilings do not leak the place did not this problem). It is best not to affect the decoration, the project is small, but can not be long-term to the downstairs leaking, the cause of the water may be the original decoration is not good, the last time to replace the angle valve to solve, but hope that the future no longer encounter water leakage.

- 1. There may be a waterproof layer of the problem, in order to solve the fundamental problem or to knock down the original tile to do waterproof. 2. If there is a problem with the water pipe, it is necessary to repair and then do waterproof again.

- Q: How is Sophia Wardrobe?

- Sophia Wardrobe advantage ? 1, ultra-high panel. Sofia can provide up to 2.8 meters of the door and side panels, wardrobe doors do not have splicing can be direct access to the ceiling, noble and elegant, extraordinary style. ? 2, two-color panels up to 10mm French original imported panel, woody strong, and both sides of different colors, can be used for face, more fashionable. ? 3, the unique top brush with nylon fiber material (steel products applicable), can be clever to keep the balance of the door guide, from the slowdown, to reduce the door back and forth collision is sliding sliding door system of high-tech. ? 4, choose to enrich a dozen independent sub-cabinet, a dozen wardrobe accessories, dozens of colors, any choice of free.

- Q: What is the ceiling of the cinema?

- The use of clear frame keel, keel width 15mm or 24mm. Use black paint keel, need to be customized. To place sound on other ceilings, please note the carrying capacity of the original ceiling

- Q: We had our carpets removed a while ago and installed laminate flooring instead.As a result, the house is not as warm as it used to be.Will it help if I add R13 insulation in the basement ceiling ? Will it keep the living room floor (which is just above the basement) warmer ?On the same manner, will adding another layer of insulation to the attic help in the winter and summer as well ?As for the mositure barrier paper, if I understand correctly, it should be facing up both cases, right ?

- I post some insulation in my storage that's below my mattress room and that i do experience the version - I grew up in Philly and we live in a row residing house and our basement replaced into some what under floor so all we had to do replaced into insulate the residing house windows - yet once you have partitions that are dealing with the wind you are able to ought to post some thing there additionally - warmth will upward thrust some in case you are able to insulate your attic that's going to help - in case you have severe ceilings you additionally can decide to think of a pair of ceiling fan

- Q: How good is the Burton Hotel in Dubai?

- The only seven-star hotel in the world - Dubai, United Arab Emirates

- Q: need a ceiling ladder storage rack that can hold a 28 ft. fibreglass ladder?

- Are you asking me if I need a ladder rack? Or are you wondering what to use to hold a fiberglass ladder to the ceiling? Option 2) you could use 2 giant hooks that screw into the ceiling, and that should be sufficient. However: since those ladders are a bit heavy, why not do yourself a favor and store it horizontally on a couple hooks near the bottom of the wall instead? It's a lot more convenient that way, and safer for everyone concerned.

- Q: Is there any decoration material that can replace the glass on the sliding door?

- Double 5mm white glass

Send your message to us

Ceiling Tiles 2x4 Fiberglass Ceiling Materials

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 3500 M2 per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords