Fiberglass Drop Ceiling Tiles 2x4 - Acoustic Fiberglass Ceiling Well Quality 15mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Ceiling

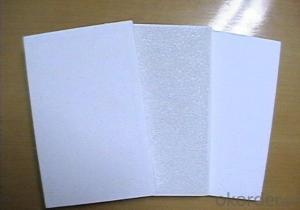

The tiles are manufactured from high density fiberglass wool.The visible face has a decorative fiberglass tissue and the back of the tile is covered with normal tissue.The four edges of the tile are sealed and have grooves. It can be jointed together without suspended system. The tiles will cover the suspension system after installation. They are are suitable for loe flap ceiling space and concrete-made, wooded-made or gymsum ceiling.

Installation method:

Use screw to fix the smooth roof. The tiles can be connected after making grooves on each two jointed edges.

Tiles are easy to trim and install

Both inches and metric grids are available

Main Characteristic:

Non-combustible

No sagging,wrapping or delaminating

Green building material

Excellent sound absorption

Application:

Halls,classrooms,offices,shopping centers.etc.

Acoustic fiberglass ceiling contains a better perfomance in tension strong, light weight, so it is easy to trim and install for interior decoration, with T-grids for suspension system or glue, nail or good material could come with fiberglass ceiling baord. Thus an excellent artical work need a high quality acoustic ceiling board, also high quality.

Energysaving is a trend for our 21' era, new product like fiberglass ceiling tile could in place of traditional products one day. Which depends on functional characters: little deflection of geometry dimention, no radiocative property, specific activity of 226Ra: Ira ≤1.0 and specific activity of 226 Ra 232 Th, 40 K: Ir ≤ 1.3. Both products and packages can be recycled.

- Q: Old house would like to decorate their own what good material?

- First get the wall look ah, ah big white powder or paste wallpaper. And then get a video wall. The ground re-leveling, shop a floor. The door or about a door or a door frame. In short, according to their own preferences, the house dress up. Such as the use of Dulux environmental paint to paint the wall into other colors, refreshing thing. The toilet can be decorated with very style mosaic.

- Q: Home improvement materials used most of the main, what?

- Tiles, wood flooring, man-made sheet, paint, wallpaper paint, hardware, cabinets, sanitary ware, hardware, electrical appliances (kitchen and toilet), lamps curtains,

- Q: What equipment they need to build a studio, there is no detailed list and price. Mainly recording the kind of studio studio.

- Small studio lighting solution 1 (background light): 36w three-color soft light 2 (top light): 55w three primary colors soft light 3 (side light): 36w three-color soft light 4 (face light): 36w three primary colors soft light Lighting technical parameters: A: illumination: to host as the center, the average illumination of 800 ~ 1000LX; B: color temperature: the average color temperature of about 3200K; C: light ratio: backlight: main light = 1.5 (2): 1 main light: vice = 1.5 (2): 1 D: power: the total power consumption of 1668W; E: cable: a flame retardant cable; F: according to the actual needs of the use of three-phase four-wire system or other means; G: lamp height: located in the plane from the platform 1.6 ~ 2.5 meters; H: light for the constant constant cold light source three primary colors, light light soft, shadows fade, not dazzling, almost no increase in indoor temperature; I: the angle of light imported by the United States 1324 type; J: lamp ballast for imported Philips or OSRAN; K: lamp for the import Philips930 type or OSRAN32930 type; L: Reflector system with Japanese imports of bright permanent mirror reflective stainless steel plate.

- Q: My neighbor told me that there is no attic space in the main bedroom. It is a 2 story house, but the master bedroom is the ONLY room that is significantly hotter than the other 2 rooms. Is it possible to put some sort of insulation over the existing ceiling and then drywall over it? Or....??????

- In answer to your question, yes, you could use one of the sheet insulations such as rigid fiberglass or expanded polyurethane, but as one poster said it would likely be less expense and hassle if you just took the existing ceiling down and insulated with bats or spray foam.

- Q: I have removed textured wall paper from ceiling, the plasterboard is in very good nick, but has gaps between sheets?I really dont want to have to get it all re-skimmed.would the correct approach be to plasterboard joint tape, then lining paper over over it, before painting?Id appreciate a how to.....

- when you say plasterboard if your talking about sheetrock than yes, youll be ok...if its plaster then you best bet would be to put a fresh layer of 1/4 sheetrock over it and have a nice new flat ceiling that wont crack up on you.

- Q: Indoor ground artificial marble paving after the bow is the reason

- Ordinary decoration materials (1) Hall: floor or ceramic tiles, wall paint, wall panels, ceiling, spray paint gypsum board, gypsum line curtain box, wire buried, installed flat switch, socket, , Modified double-window structure, wood door modified synthetic leather or wood package with doors, set wooden hanging mirror line. (2) bathroom: sealed tube, to change the tube, equipped with towel rack, mirror, dresser, floor tiles, wall tiles, color ceramic face hatred and moisture-proof lights, electric stove, exhaust fan. (3) Kitchen: floor tiles, wall tiles, tampering, water heater, range hood, stainless steel stove, modified console or stove cabinet, fitted closet and exhaust fan, class, partition cabinet. (4) balcony: floor tiles, fence decoration, closed window. Luxury decoration selection (1) the main hall: shop high-grade wood floor or shop wool overall carpet, wall stickers import wall covering, ceiling, for light steel keel gypsum board, set wooden hanging mirror line, installed plaster line curtain box, Board, wire laying, installation of casing, equipped with plane switches, sockets, loading wall lamp, chandeliers, aluminum alloy with double windows, aluminum partitions, aluminum doors, noise walls. (2) bathroom: sealed size, change the dark tube, glazed ceramic wall, mosaic ground, color ceramic concave column foot basin, color ceramic bathtub, sitting bucket, ventilation, stainless steel towel rack, Even mirror dresser, soap pan, roll tray, moisture-proof lamp, paint moisture-absorbing ceiling, shower or shower aluminum door. (3) kitchen: wall paste white glazed ceramic tiles, ground shop red brick, equipped with marble console, aluminum alloy closet, multi-eye gas stove, water heater, dirt bucket, stainless steel sink, dishwasher, moisture , Range hood, exhaust fan, kitchen cabinets, chrome taps, aluminum alloy spacing, PS glass doors, aluminum doors and windows, tableware, metal mesh cooker hanging plate. Balcony and kitchen unified decoration.

- Q: Again, none of the pink fiberglass lining actually touched me, so maybe since there was an air circulatory system on low, maybe some of the fiberglass dust from it is irritating me?

- It's is not like catching the flu. You need to be directly exposed and exposed for a long time. If you were you'd know it by now. That little tickle or scratchiness could be from anything but is highly unlikely to be from the fiberglass. I can understand your concern because I've just gotten some on my skin and wouldn't want that in my lungs But relax you're fine. If you feel the need to go back and you want, wear a mask. Even those cheap paper surgical masks would be fine. God bless.

- Q: I have hanged the drywalls on both the ceiling and walls. My questions is how should I tape the joints between the ceiling and walls? Should I use a regular paper tape, a fiberglass mesh or a paper corner bead (inside corner)?

- I do Sheetrock repairs in apartments and houses. I have found that the paper tape works better in this application. after you put the mud in the joints tear of a piece of tape to cover the area you feel comfortable with. Usually five or six feet. Fold the tape in half. After you fold it it will look like a apiece of angle iron. then take the putty knife and push it in place as you press in in place be sure an keep it pushed into the joint so you do not leave a bubble. Then feather the mud as you go .Add another piece overlapping each piece slightly. When you get to the end butt the joints in the corner. Be sure and look back and make sure it stays tight in the groove. Good luck

- Q: What signs on plastic products are non-toxic

- HDPE high density polyethylene Common white vials, cleaning supplies, bath products. Do not use it again Cups, or used to make other containers. Clean is not complete, do not use.

- Q: Interior decoration of the most commonly used several decoration materials

- Interior Decoration Materials: Wall Paints Wall Paints, Organic Coatings, Inorganic Coatings, Organic Inorganic Coatings Wallpaper wallpaper paper wallpaper, textile wallpaper, natural materials wallpaper, plastic wallpaper Decorative plate wood decorative wood-based panels, resin impregnated paper high pressure decorative laminated board, plastic decorative panels, metal decorative panels, mineral decorative panels, ceramic decorative murals, perforated decorative sound-absorbing panels, flocking decorative sound-absorbing panels Wall cloth glass fiber stickers wall cloth, hemp non-woven wall cloth, chemical fiber wall cloth Stone Ornament Natural Marble Finishes, Natural Granite Finishes, Artificial Marble Finishes, Terrazzo Veneer Wall tiles ceramic glazed tiles, ceramic wall tiles, ceramic tiles, glass mosaic.

Send your message to us

Fiberglass Drop Ceiling Tiles 2x4 - Acoustic Fiberglass Ceiling Well Quality 15mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords