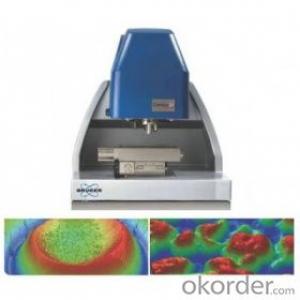

Three-dimensional surface measurement system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brooke NPFLEXTM 3D surface measurement systems for precision manufacturing unprecedented detection performance, shorten development time, improve product quality and productivity. Based on the principle of white light interferometry, this non-contact system offers many advantages over traditional contact measurement technology, these instruments include coordinate tester (CMM) and Stylus instrument. Measurement advantages including access to high-resolution three-dimensional images, quick rich data collection, to help users better understand the performance and features. Decades of accumulated experience and a large sample interferometry instrument design, NPFLEXTM flexibility is the first measurement of large sample size optical measurement systems, and can quickly and efficiently obtain samples from micro to macro and other different aspects.

Its flexibility can be used to measure performance in the angle of the surface type and characterization of a larger and more unpredictable

Innovative design makes it possible to measure the part of space (sample) bigger, more shape

Open gantry, custom fixtures and optional swing measuring head can be easily measured want to test sites

Efficient three-dimensional surface information measurement

Each measurement can get a variety of analytical results

Easier access to more measurement data to help analyze

Nanometer resolution in the vertical direction to provide more details

Interference technology to achieve sub-nanometer level pixel vertical resolution of each measurement point on the

Industry for many years has been validated using interferometric techniques provide statistically significant data, and to provide protection for the increasingly demanding processing

Quick access to measurement data to ensure that the test quickly and efficiently

Minimal sample preparation time and measurement preparation time

Measurement than the contact (a line) larger field of view (one side) to obtain a surface more data

Measuring unreasonable size, sample size, flexible operation, accurate and efficient

Typically, relatively large measurement sample or a special shape, when the specific surface of the sample, often takes a long time for the samples processed by the line of cut before the line of measurement. Today, the development of a new type of NPFLEX measurement system has a large measuring space, the maximum measured 13 inches, this innovative space designed to measure larger samples and more complex shapes. Open gantry, custom fixtures and optional swing measuring head can be easily measured want to test a sample site. Open architecture and Bruker's patented optical lens cast point / tilt design, implementation to achieve the desired longer working distance numerical aperture. This makes good measure NPFLEX groove, high aspect ratio holes, or undulating surface larger works.

Excellent quality, solid as a rock

NPFLEX overall design of both durable and marble machine can withstand up to 170 pounds of the most important samples. Open gantry design flexibility to measure and characterize the larger type face more unpredictable angles. Custom grips and optional swing measuring head can be easily converted to measure the direction and characterization of samples at different locations. During the experiment, using NPFLEX, for the sample size, the sampling process and the requirements of the experimental environment, many are relatively loose, so that the completion of the experiment can be convenient and flexible, to help producers obtain precise data nature of the product.

Three-dimensional surface information measuring nanometer resolution

Many people on the surface properties of the sample of interest, but the nature of these samples to obtain required Austrian quantitative detection of a large number of sample surface galaxies. Many large sample applications in aerospace, automotive, medical implant industry in. Often only by means of a two-dimensional contact detection by the line characterization tool is limited to obtaining a single linear data. Two-dimensional scanning of the sample surface profile can be provided, but can not in-depth study of the sample surface texture more precise details.

NPFLEX test system using white light interferometry principle, each measurement point can achieve a three-dimensional surface topography information gathering, and has a sub-nanometer vertical resolution. The data collected from the most important limitations of the size of the probe, and efficient measurement of the three-dimensional surface information can be obtained in addition to a variety of surface roughness analysis, more measurement data to help analyze the nature of the sample.

Fast access to data, to ensure rapid and efficient test

NPFLEX three-dimensional measurement system capable of flexible and efficient access to a large number of test data. Greatly reducing sample preparation time and measurement program to set the time, the operator can quickly replace the sample, and the sample without having to fully grasp the premise of the shape and surface morphology of the barrier surface of the sample is measured. Only need less than 15 seconds, you can well done data collection and analysis of a measuring point.

Autofocus, light intensity adjustment, and other supporting software, which greatly saves time measurement and analysis, but also the needs of the operator in accordance with the experiment, tailored to optimize the experimental program, without affecting the accuracy and quality of the data. NPFLEX can use efficient, fast, flexible, accurate access to high-precision measurements of large parts, providing a one-stop solution for measurement.

NPFLEX three-dimensional measurement system - a new characterization techniques, concepts and eventually became a reality

Widely used in research and development

Production process and product quality control

Failure Analysis

Performance measurement system, a unique open large sample sets, flexible and efficient access to accurate data

- Q: The urine analyzer belongs to several kinds of medical instruments

- Species are now testing glucose meter range, performance is also different, in order to ensure the blood glucose meter, reliable performance, accurate measuring results, the best to the nearest regular medical equipment company to inquire, compare the determination principle all blood glucose meter: blood glucose meter from the working principle of two respectively, a photoelectric type, one is electrode type. A blood glucose meter similar CD player, a photoelectric head, the utility model has the advantages of cheap, disadvantage is the detection head exposed to the air, it is easy to be contaminated, affect the test results, the error range of plus or minus 0.8, short service life, generally within two years is more accurate, is recommended after two years the use of photoelectric type machine to customer service service station with a head calibration and maintenance. Johnson's steady, steady pace, Roche's "Le Kang", "Luo Kang" congruence belong to this type.

- Q: How to judge sample residue in liquid analysis instrument

- Manual injection, empty breaking needle, automatic sampling, sampling rate is zero.

- Q: What does the resolution parameter of the electrolyte analyzer mean?

- An electrolyte analyzer is an instrument for detecting potassium, sodium, chloride, calcium, and lithium ions from a sample.

- Q: Which is good for full automatic bacterial identification and drug sensitivity analyzer?

- The French bioMerieux, it is the authority of microbial community in the world.

- Q: Carbon sulfur analyzer which brand is better? Laboratory use

- If there is a guarantee to buy domestic suggest you take a look at Beijing shidailihe and company Wanlianda brand old enterprise quality

- Q: Instrument features of ICP-AES analyzer

- Quick analysisICP-AES method, interference, low time distribution, stable linear modelThe width of the enclosure can simultaneously read the characteristic light of a variety of elements under testQuantitative and qualitative analysis of various elements at the same timeA sample of 5 elements can be completed in 3 minutes

- Q: What safety matters should we pay attention to when using chemical reagents and using analytical instruments?

- In the sample with a large number of pH, the pH should also choose excellent chemical pure. At the same time, the preparation method of the purified water and the washing method of the glassware are also required,. The analysis also used as analytical reagent, gr.

- Q: Audio analyzer for audio analyzer

- The audio analysis instrument mentioned here refers to not only can measure the microphone, audio amplifier, speakers and other types of single audio equipment of various electro acoustic parameters, can the overall performance of combination test combination audio mixer, audio equipment analysis instrument. At present, the market has been the emergence of measurement can be used for all kinds of audio equipment, analytical instruments, such as distortion analyzer, spectrum analyzer, frequency counter, AC voltmeter, DC voltage meter, oscilloscope audio etc.. These rack type hardware instruments based on various functional circuits are easy to use and have high measurement accuracy, and have been widely used. Audio equipment manufacturers can analyze the performance of the instrument inspection equipment using audio, discovery of defects, and for the design of the equipment manufacturing is improved, consumers can also use audio analysis instrument to evaluate the equipment, choose the right product.

- Q: What kind of jobs does the analytical instrument include?

- Are usually detected, product testing. Employment is not difficult, but wages are generally not high, and very bitter, in fact, most people do not understand this industry, that the laboratory is very idle, but in fact not.

- Q: About chromatographic instruments

- Gas chromatography can be used as a liquid sample.

Send your message to us

Three-dimensional surface measurement system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches