Teflon Fiberglass Fabric Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

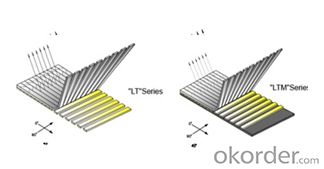

(0°/90°) series mat:

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡)。The product has a maximum width of 100 inches.This product can be used for manufacturing boats,cases and shell of car.

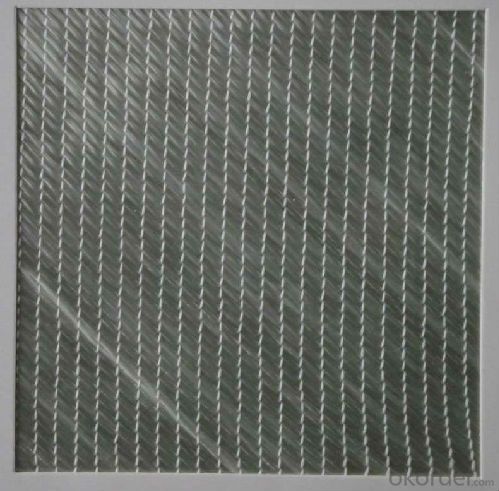

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-LTMC3205 | 1272.69 | 607.6 | 491.86 | 152.58 | 20.65 |

E-LTMC3205-HS | 1388.43 | 607.6 | 607.6 | 152.58 | 20.65 |

E-LTMC3208 | 1394.75 | 607.6 | 491.86 | 274.64 | 20.65 |

E-LTMC3610 | 1541 | 607.6 | 607.6 | 305.15 | 20.65 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass fabric be used for making shoes?

- Yes, fiberglass fabric can be used for making shoes. It is a versatile material that offers strength, durability, and resistance to wear and tear. It can be used in various shoe components such as the upper, reinforcement, or insoles to provide added support and stability. However, it is important to note that fiberglass fabric may not be as commonly used as other materials like leather or synthetic fabrics in the shoe manufacturing industry.

- Q: Can fiberglass fabric be used for insulation in chimneys and flues?

- No, fiberglass fabric should not be used for insulation in chimneys and flues. Fiberglass fabric is not suitable for high-temperature applications like chimneys and flues, as it can melt or catch fire when exposed to extreme heat. Additionally, fiberglass fabric may not provide adequate insulation to prevent heat transfer, which is essential in chimney and flue systems to maintain proper airflow and prevent the risk of fire hazards. It is important to choose insulation materials specifically designed for high-temperature environments, such as refractory insulation or ceramic fiber insulation, to ensure safety and optimal performance in chimneys and flues.

- Q: Can fiberglass fabric be used for reinforcement in construction materials?

- Yes, fiberglass fabric can be used for reinforcement in construction materials. It is a popular choice due to its high strength-to-weight ratio, durability, and resistance to corrosion. It is commonly used in applications such as reinforcing concrete, strengthening structural elements, and enhancing the overall performance and longevity of construction materials.

- Q: Can fiberglass fabric be used for making backpacking or camping gear?

- Yes, fiberglass fabric can be used for making backpacking or camping gear. Fiberglass is a strong and durable material that is resistant to tears and abrasions, making it suitable for outdoor activities. It is also lightweight, which is essential for backpacking where every ounce matters. Moreover, fiberglass fabric has excellent insulation properties, providing warmth when used in sleeping bags or blankets. Additionally, fiberglass is water-resistant, making it suitable for use in tents or shelters to protect against rain or moisture. Overall, fiberglass fabric is a versatile material that can be used in various camping and backpacking gear to enhance durability, insulation, and protection.

- Q: Can fiberglass fabric be used for making surfboards?

- Surfboards can indeed be made using fiberglass fabric, which is actually a very commonly used material in surfboard construction. The reason for its popularity lies in its impressive strength, durability, and lightweight nature, all of which make it perfectly suited for manufacturing surfboards. To create a strong and rigid structure, the fiberglass fabric is typically layered on top of the foam core of the surfboard and then laminated with resin. This combination of materials ensures that the surfboard can withstand the powerful forces exerted by waves while still maintaining the necessary flexibility for maneuverability. Furthermore, fiberglass fabric allows for easy customization of the surfboard's shape and design, making it a favored choice among both surfboard shapers and manufacturers.

- Q: Can fiberglass fabric be used for reinforcement in concrete structures?

- Yes, fiberglass fabric can be used for reinforcement in concrete structures. Fiberglass fabric, also known as fiberglass mesh, is made from woven fiberglass strands and is commonly used in construction applications. It offers several advantages as a reinforcement material in concrete structures. Firstly, fiberglass fabric has high tensile strength, which means it can withstand significant forces without breaking. This strength makes it capable of enhancing the durability and load-bearing capacity of concrete structures. It helps to distribute the load more evenly throughout the concrete, reducing the risk of cracks and structural failure. Secondly, fiberglass fabric is lightweight and easy to handle. Unlike traditional steel reinforcement, which can be heavy and time-consuming to install, fiberglass fabric is lightweight and can be easily cut, shaped, and applied. This makes it a convenient option for reinforcing different parts of a concrete structure, such as walls, columns, and beams. Additionally, fiberglass fabric is resistant to corrosion and does not rust like steel reinforcement. This corrosion resistance is particularly beneficial in environments that are exposed to moisture, chemicals, or other corrosive elements. By using fiberglass fabric, the risk of degradation and deterioration of the reinforcement over time is reduced. Furthermore, fiberglass fabric is non-conductive, which means it does not conduct electricity. This property can be advantageous in certain applications, such as in structures that require electrical insulation or in environments with electromagnetic interference. Overall, fiberglass fabric is a versatile and effective reinforcement material for concrete structures. Its high tensile strength, lightweight nature, corrosion resistance, and non-conductive properties make it a suitable choice for various construction projects. However, it is important to follow proper installation guidelines and specifications provided by manufacturers to ensure optimal performance and longevity of the reinforced concrete structure.

- Q: Are fiberglass fabrics resistant to rot or decay?

- Yes, fiberglass fabrics are inherently resistant to rot or decay due to their non-organic composition and durable properties.

- Q: How does fiberglass fabric perform in weight-to-strength ratio?

- Fiberglass fabric possesses a weight-to-strength ratio that is relatively high, indicating its lightweight nature alongside significant strength and durability. This attribute stems from the unique composition of fiberglass, comprising minute glass fibers interwoven together. These fibers are incredibly robust and inflexible, enabling the fabric to withstand substantial levels of tension and compression. When compared to materials like steel or aluminum, fiberglass fabric is considerably lighter while still maintaining comparable strength. This characteristic renders it an optimal selection for situations where weight holds critical importance, such as in the aerospace or automotive sectors. Furthermore, the fabric's high strength permits the construction of structures and components capable of enduring heavy loads without excessive weight addition. By adjusting the weave pattern and the density of the glass fibers, the weight-to-strength ratio of fiberglass fabric can be further optimized. For instance, a tighter weave or increased fiber density can enhance the fabric's strength, albeit potentially increasing its weight. Conversely, a looser weave or reduced fiber density can reduce weight, albeit potentially compromising some strength. All in all, fiberglass fabric exhibits commendable performance in terms of its weight-to-strength ratio, presenting a lightweight and robust material applicable across a broad range of fields. Its versatility and durability render it a popular choice within various industries where the balance between weight and strength holds crucial significance.

- Q: How are fiberglass fabrics manufactured?

- Fiberglass fabrics are manufactured by weaving or knitting strands of glass fibers together to create a flexible and strong textile material. The process involves melting glass into fine filaments, which are then formed into yarns. These yarns are then woven or knitted into various patterns, depending on the desired strength and texture of the fabric. The resulting fiberglass fabrics can be used in a wide range of applications, including insulation, reinforcement, and composite materials.

- Q: What is the moisture resistance of fiberglass fabric?

- Fiberglass fabric has high moisture resistance due to its inherent non-absorbent nature and the hydrophobic properties of the fiberglass material.

Send your message to us

Teflon Fiberglass Fabric Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords