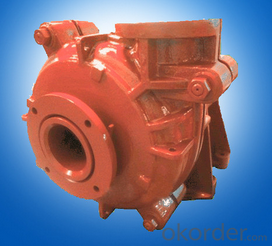

TDA Series Slurry Pump Equipment for Gold Mine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications

1.Model: TD

2.Material: high chrome alloy or rubber or ceramic

3.Flow Rate: 10.8-5400m3/h

4.Head: 3-118m

5.ISO9001:2008

2. Application

Various centrifugal pumps for pumping heavy slurry in agriculture,petrochem,manufacturing,energy and mining.

3.Features

1) Decrease electricity consumption and increase pump life

Our uniquely designed pumps limit slurry contact thus the efficiency is significantly higher and hence very big conventional slurry pumps can be replaced by a pump with a 20% of more smaller motor without affecting pumping performance. If energy bills and high cost of ownership is of concern, these pumps are the answer.

2) Lime and ash applications

Lime and ash pumping applications are particularly difficult for centrifugal slurry pumps because acceleration inside the pump causes the slurry to clump together into a solid clay degrading performance. We have a unique solution proven to work more efficiently and outlast conventional pumps.

3) High viscosity liquids

Superior throughput rates compared to gear and vane pumps using a unique new design. Great for bitumen, all emulsions and fats.

4.Material

1. high chrome alloy: strong abrasive resistance

2. rubber: corrosive resistance

3. ceramic: abrasive & corrosive resistance, high temperature resistance and cavitation resistance (Please refer to detailed introduction as follows)

5. FAQ

1 Are CNBM pumps available in DIY stores?

Yes, currently, we’re available for DIY stores all over the world.

2 Where do I have to send pumps for service?

You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

3 Are your pumps acid-proofed?

To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

- Q: im attaching a motor from another filter onto my homemade filter. but i dont want to have to run a cord all the way from the pond to a powerplug. does anyone know of another way to such water into a filter without using electricity? some kind of siphon?

- 1. I had an electrician put a buried cable in the ground coming up to a weatherproof post with outlets and an on-off switch. It was not as expensive as I thought it would be. 2. You can put the water pump and filters by the house or even inside and run buried water pipes out to the pond, or just put the pump inside and have the filter by the pond which would run by water pressure or gravity. 3. A windmill or solar panel. A siphon uses potential energy stored in the water to work. Once the water has dropped through the siphon, there is no more energy to draw from and the siphon stops. A windmill or solar panel could provide the power to lift the water back up and make the process continuous, or at least while it's windy or sunny. However when pricing these two options even though they would be very cool if you have the large yard to accommodate them, they turn out to cost much more than either 1. or 2. and have much higher maintenance costs associated with them. 4. If it's a very small pond, you can get a solar powered filter/fountain that looks like a floating plastic lily pad. My son had one of these, but it only worked on the sunniest of days, and lasted one summer before wearing out. If you add a large block of filter foam over the intake it may last a little longer. Rinse it out two or three times a week.

- Q: how do I know my water pump failed. 98 mustang V6 started to leak coolant from the front lower part of the the engine. How do I know for sure my pump is bad? Did refill and kept on leaking as I manage to get home. Little help please!

- A leaky radiator could also be the cause of leaking coolant. Sometimes waterpumps rattle as they're dying.

- Q: The truck is a 1982 Ford pickup F100. We didn't realize it was an F100 at the time and we put the F150 water pump on it. The water pump fits perfectly, but is this going to mess up the engine at all?

- No it will not hurt the motor as long as the pulley for the belt lines up with the crankshaft pulley like the original one did. If they don't line up you will start chewing through belts

- Q: One month ago, mechanics replaced water pump for my car, 04 dodge stratus, 100000 miles. When I went to get the car, there was big noise coming out from engine. The mechanics told me it was because of sediment in auto oil system and he show me some sediment he took out. I know little about car so I thought he was right. But now the noise changed and engine light came on. I went to firestone to check it. The report said timing jump and cranked. The second day the engine died totally. And I went to another two mechanics. They said the previous one who replaced the water pump did something wrong to timing chain. But that mechanics didn't admit it. What can I do?

- You're on thin ice with this, unless you had the timing belt replaced before 90,000 miles. That big noise was the pistons hitting the valves after the timing belt slipped, or more likely, broke from being worn out. When the engine's water pump is driven by the timing belt, the belt must be slacked to get the pump off, then tightened back up after the new pump installation. That old belt couldn't hold up under the tension. It's just bad luck for the mechanic he didn't think to question the age of the timing belt and insist that it be replaced. Of course that would cost a bit more. It will be an uphill battle. You might as well find a used engine if you want this car back on the road. Good luck to you.

- Q: I've always wondered how a water pump moves water through a pipe. A fan moves air by spinning a propeller-like set of blades, but does a water pump work the same way? Or is there some other kind of mechanism inside the pump that draws water from one place and pushes it to another?

- Most water pumps work on the same principle as a fan, only encased in water tight structures and using impellers. It draws water from one source and pushes it to another.

- Q: And if it needs to be replaced, does that spell trouble for a car? I see a car I might like to buy, but the ad says that the water pump needs to be replaced. Someone please enlighten me. Thanks.

- a water pump circulates the coolant thru the radiator to keep the engine cool. Some are outside of the engine and fairly easy to replace. others are stuck in at rediculous places and require special tools and dynamite to remove. It better be an awful nice car but at least the seller was honest about it so maybe he would be honest about th rest of the car. Its not a BIG expense but maybe you sould get an estimate so you know and can add that to what you will have to pay for the car. and get it fixed right away so you don't have to replace the engine too.

- Q: So when you exercise, is the amount of salts and water pumped out in the loop of henle reduced, if so why????

- Salt impacts the osmotic interest of a cellular. this implies that once it somewhat is modern-day in severe concentrations interior the cellular, water strikes into the cellular with the aid of osmosis. This extra water getting into the cellular could reason the cellular to rupture. interior the kidneys an identical mechanism applies. whilst the concentration of NaCl is severe interior the tubules extra water is retained interior the physique. besides the incontrovertible fact that, whilst the concentration of NaCl is low interior the Kidney tubules much less water is retained by utilising the physique.

- Q: Yesterday my car was making squeaky noises in the front and then the fan came on FULL FORCE it sounded lik an airplane. It then started to over heat. I looked to see if there was any antifreeze/coolant in it and it was BONE DRY. I found out the water pump is bad. My boyfriend wants to change it himself but he doesn't know if where it is located is so complex he should take it to a mechanic. He has changed water pumps before. If you know anything about this.. your advice is very much appreciated!!

- Water pumps arent too bad to change. Just follow the hoses to the pump, should be connected to the sepentine belt. Your diagnosis seems to be correct,

- Q: Water pump 50HZ impeller and 60HZ what is different, why not the same?

- Water pump 50HZ impeller and 60HZ impeller, its outer diameter is not the same, 60HZ impeller slightly smaller. Because the speed of the impeller of 60HZ is faster, the impeller is a little smaller.Flow rate and speed, impeller diameter into a relationship: Q1/Q2 = n1/n2=D1/D2;Head and speed into two relations: H1/H2 = (n1/n2) 2Motor shaft power and speed into three relations: P1/P2 = (n1/n2) 3From the above deduction, we can know that the motor speed formula is n=60f/p, in which n is motor synchronous speed, and F is supply frequency. P is the pole number of the motor. It is known that the power supply frequency of the motor is proportional to the speed of the f. Therefore, to obtain the same head or flow, high speed, to use a smaller impeller.

- Q: the question i have is can the pump be turning and not leaking but not pump water??? i know the olden days (the good ole days) as long as the impeller was turning it would pump water! leaking seal is when it went bad,or locked up..like a box fan blade as long as it is turning its moving air...

- some vehicles could have a loud water pump without extra issues. often times a defective water pump might reason problems with the cylinder head if the engine overheats. So examine right here: one million. is there steam in the exhaust smoke? 2. Do drops of water look on the tip of the exhaust? the two between the above can mean a warped cylinder head or blown gasket. if it is so, do no longer purchase. in case you have any concerns, get the motor vehicle regarded at by a mechanic.

Send your message to us

TDA Series Slurry Pump Equipment for Gold Mine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords