Suspended Ceiling Grid Main Runner - Suspension Ceiling Grid System Main Tee

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

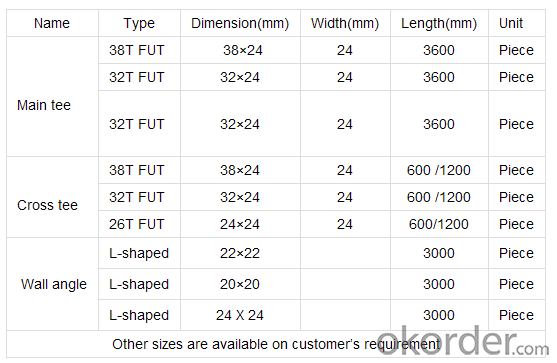

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: Can you touch up drop ceiling tile with paint ? I don't want to remove a tile for a scratch or scuff.?

- You sure can Just finished my recroom turned out GREAT. If your grid system is the same colour roll the whole cieling don,nt use to much presure on the roller, I used C.I.L. Problem solver it,s a primer but makes nice job of tile. Do,nt for get youe drop sheet have fun,

- Q: Do you need a light steel keel or a wooden keel base? If there is, usually light steel keel or wood keel, if it is wood keel, need to brush what paint, fire paint to brush it?

- Not required. The process standard for industrial and civil construction works, the exterior panel dry hanging process. The process is the use of corrosion-resistant bolts and corrosion-resistant flexible connectors, marble, granite and other decorative stone dry hanging on the outer surface of the building structure, stone and structure between the left 40 ~ 50mm cavity. The finishes made with this process allow an appropriate amount of displacement to be absorbed by wind and seismic forces to absorb part of the wind and earthquakes without cracking and shedding. When the wind and the earthquake force disappears, the stone is also reset with the structure. Compared with the traditional wet operation process, the process can eliminate the grouting process, can shorten the construction period, reduce the building weight, improve the seismic performance, more importantly, effectively prevent the grouting in the salt and other pigment penetration of stone pollution, Its decorative quality and perception effect. In addition, due to seasonal changes in outdoor temperature caused by changes in the outer surface expansion and contraction, so that the decorative panels may fall off, this process can effectively prevent the occurrence of worn off the board accident. This dry pendant panel installation process can also be used with glass curtain wall or large windows, metal trim panel installation process and other supporting applications. Now many large domestic public building stone interior and exterior trim panel installation works to dry hanging process is becoming increasingly common.

- Q: This is one of the new low-profile ones that hangs only 1 1/8 below the joists. The main drain PVC pipes all run together at one point next to the foundation (poured, not block) wall. There is about a 5-6' section wide that all hangs about 4-5 below the joist and sticks out 4-5 from the wall. Question is, how do I go about putting the drop ceiling around this mess? Do I build a case for it and block it all in with nice cedar stained wood? I need some suggestions please!

- i would really need to see this for an honest answer. my only suggestion would be to block it all in with cedar like you said, but rather than just blocking it in, why not make a cabinet that is the same measurements as what you would need to block off the eyesore and run it the whole length off the wall or ceiling. this way you would have a long, narrow, and wide cabinet and it wouldnt look like you just covered it up it would also have a functioning purpose.this would be especially useful, if you have children, to keep harmful things out of their grasp.

- Q: Light steel keel manufacturers is not only the production of light steel keel?

- In addition to our light steel keel will produce paint keel, triangular keel, stone and so on. But small factories are generally only the production of light steel keel.

- Q: I am using Dutch Boy Ceiling Solutions, the kind that goes on purple and dries white. I primed with FastPrime over new drywall. I put one coat of the DB on and it looks like poo. I painted in grids, but got uneven coverage and you can tell where the drywall tape was. Maybe the roller I used was wrong for the app? Or did I just do a crummy job. I have painted many a room before, but not many ceilings.

- New drywall may need multiple coats to get complete coverage. Do not paint in a grid. Start at one side and work across always keeping a wet edge. The method you are using will always produce uneven results.

- Q: Want to install track lighting on a dropped ceiling in the cellar. It's one of those lovely styrofoam-like tiled ceilings with the metal grid.

- I believe that it can be done. There are so many designs and with people that are very knowlegable in the lighting field I 'm sure they can find a way to hang them

- Q: Home decoration with wood keel good or light steel keel good

- Specifically to see what kind of top hanging, if it is pvc wood keel of course, if it is gypsum board, of course, light steel keel. Integrated ceiling.

- Q: How do I install dropped ceiling in basement?

- why would you want to do that?

- Q: Decoration, said light steel keel gypsum board wall what is the use?

- Energy saving and environmental protection, policy support. Gypsum board production energy consumption is very low, in the regular annual production capacity of 20 million square meters of production lines per square meter double-sided monolithic gypsum board partition, the production of energy consumption does not exceed 3kg standard coal, and per square meter Clay brick wall production energy consumption is 4-12kg standard coal. In 2000, the former National Building Materials Bureau, the Ministry of Construction, the Ministry of Agriculture, the Ministry of Land and Resources, the Office of Building Materials (2000), published a list of large and medium cities with solid clay brick tiles. Light steel keel gypsum board will be the new wall materials in the most development potential of one of the products, but also to replace the solid clay brick is one of the most ideal and most economical wall materials.

- Q: I'm doing a reno in my basement and want to put crown molding up but can't imagine it looking good. Any suggestions?

- It would look absurd on a drop ceiling (metal grid and removable tiles). You wouldn't use any molding at all on such a ceiling.

Send your message to us

Suspended Ceiling Grid Main Runner - Suspension Ceiling Grid System Main Tee

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords