Wave Ceiling Grid - Steel Profile Ceiling Suspension Main Channel and Furring Channel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized s

teel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic

cold roll forming and punching machineries guarantee the high precision.

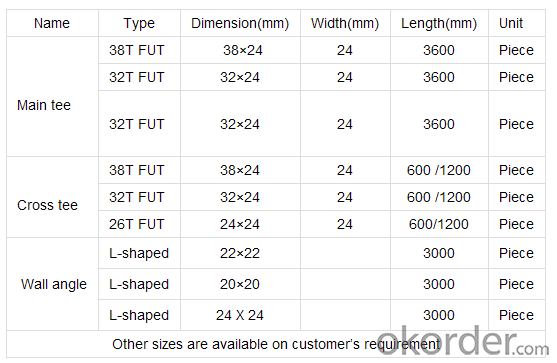

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized s

teel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic

cold roll forming and punching machineries guarantee the high precision.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

- Q: Gypsum board wall with a square with the number of light steel keel

- Gypsum board a 17.6 yuan (Taishan 0.95cm), 6 yuan per square, double-sided 12 yuan.

- Q: What is light steel keel structure

- Is the house inside the angle and I-beam, etc., located in the house walls and the beam position.

- Q: Light steel keel top ten are what

- Thickness, zinc content,

- Q: Has anyone ever designed a grid on their ceiling using say 1x3's stained or painted along sheetrock seams?

- My parents kitchen ceiling had 1x3's along the seams of the plywood. Since it was origonally a woodshed, it looked ok, but I think that type of a grid on sheetrock will look tacky. Some type of moulding might work though.

- Q: Its a Burlington coat factory store that has hanging ceiling lights and lights in a grid that need to be dusted and cleaned using a lifter and a scaffold.

- I charge $40 an hour plus equipment and materials. An estimate may come in on the high side of $3000.00 .

- Q: It is done before the floor tiles, or in the shop after the tiles to do it?

- Light steel keel partition in the shop before, after all is possible, paving the brick can be done in the tiles above, to the keel with the glue and tiles can be a solid paste the normal construction.

- Q: That is, light steel keel in the remaining after the use of the remaining material, waste recycling station after the recovery, what manufacturers to buy to do what? What is the value of use? What is the main use of light steel keel what ingredients? Hope master Xiangjie, thank you! Correct it, is the remaining corner of the remaining material, not "zoom" more than Kazakhstan, playing the wrong word, so as not to affect your answer to consider more questions

- Are generally pulled back to steel, and do more hot-rolled steel

- Q: Can you put recessed lights in a drop ceiling ?

- Absolutely! I assume that you are referring to an acoustical grid/tile ceiling. Most recessed can lights come with adjustable mounting arms that can either be nailed between joists, or in your case snapped over the grid main runners. Make sure that you follow the minimum safe clearances for your particular light. By that I mean make sure that you don't install your light too close to combustible materials. This should be labeled on the light itself at a minimum. If in doubt consult an electrician. Good luck!

- Q: I would like to hang curtains from the ceiling to function like a room divider. But I can't make any holes in the ceiling, so does anyone know how I could do this? Or any alternatives to using some fabric as a room dividerThanks in advanced

- diy decorating small dorm room

- Q: Light steel keel wall hidden acceptance of what is the hidden content? (Not a ceiling)

- 1, whether the work of the wall itself in place. 2, pipe installation within the wall is in line with specifications. 3, whether the sound insulation placed in line with the requirements.

Send your message to us

Wave Ceiling Grid - Steel Profile Ceiling Suspension Main Channel and Furring Channel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords