Ceiling Channel Suspension System Main Channel and Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Suspension System) Description

Main data

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

3.For ceiling and wall partition

4.Thichness:0.3mm-0.8mm

5.Length:3mm in common size

6.Color:Silver white

7.Shap:U and C shap

8.Used with paper faced gypsum board or other products

2,Main Features of the (Suspension System)

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

Advantages and Features:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

3,(Suspension System) Images

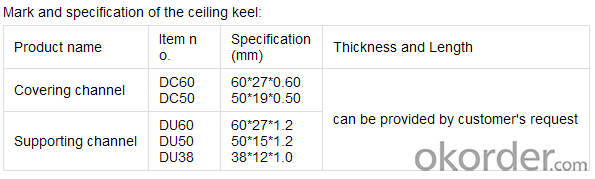

4,(Suspension System) Specification

5,FAQ of (Suspension System)

Other companies claim their tiles/panels are washable (only temporarily) and some even claim to be waterproof, but only our tiles can be washed over and over, even a million times, and never be damaged. They are completely waterproof, will never grow mold and will never sag, bow, or bend due to humidity. They have a Class A flame spread and smoke developed index that's approved for all commercial kitchens and dining areas and can be used in any standard grid for drop ceilings. They are very decorative (not industrial looking) and are perfect for not only kitchens but offices, warehouses, food processing plants, clean rooms, bottling plants, and gymnasiums. Too numerous to name them all, so basically anywhere there is a drop ceiling our tiles will work great.

- Q: What are the consequences of installing a hanging cabinet on gypsum board wall?

- You say the situation gave me the feeling you installed the location is not gypsum board wall, may be light brick. Can drill with the impact of drilling and the installation of the expansion of the bolt, not gypsum board wall can do - where the gypsum board wall can withstand the impact of the impact of drilling? Chopsticks can be used to drill the gypsum board wall, how could the expansion bolts? Or is the gypsum board wall inside filled with light brick, otherwise it is impossible to do so. In addition, if the impact of the drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon play Wear, but it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play the wood slag to - this can be seen. Based on the above analysis, I think your cabinet can be fixed, but only four screws are too little. As to how much weight? This is difficult to determine. But generally placed some clothes or slightly heavier things, should be no problem.

- Q: Light steel keel wall waterproof

- Used to resist external UV radiation, natural aging and chemical corrosion, effectively extend the coating use

- Q: Is it possible to use a hollow brick or a 95 brick?

- With hollow bricks, because it is relatively light, will not cause the floor cracking. In fact, there are many other wall materials, including light steel keel gypsum board, steel mesh, etc., both light, but also save the space as usual when you decorate the brick wall should be used 1/2 brick wall, if the hollow brick Do, the wall width of the brush with 120 thick, the main advantage is the weight of light is generally 95 brick wall 2/3, will not bring too much burden on the structure of the house itself, noise effects can be, because the hollow brick inside Hole in the arrangements on the noise function to consider, relatively speaking, 95 brick wall thickness and hollow brick is the same, heavy weight, sound insulation effect than the hollow brick to slightly better. But I suggest that the main building brick wall, then the best use of steam concrete blocks, to achieve the best results!

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- With light brick wall, there are 1.5 and 1.2 the price is about 60 it

- Q: Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Are generally used to deal with the patch to prevent brushing latex paint. But if your partition wall area is relatively large, it is recommended that you do not specifically and do not do with other walls, leaving 3-5mm edge, or posted a long time can not guarantee no cracking.

- Q: Can the gypsum board be painted on the wall

- Direct big screw can be because the back of the painting has a rope directly linked to such a simple question without the whole too much trouble

- Q: How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

- Q: 9 + 9 double gypsum board is what it means

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates. Gypsum board gypsum board (divided into ordinary gypsum board (commonly used), fiber gypsum board, gypsum decorative plate "interpretation") it to gypsum as the main material, adding fiber, adhesive, modifier, Dry from. With fire, noise, heat, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction.

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- First cut off, after the cut off does not matter. Fixed the problem to your decoration workers. No headache. The First cut off, after the ceiling so that when the ceiling of the wall at the top of the site good handling. Cut off the height of more than 3 meters a few centimeters on it.

- Q: Light steel keel partitions and finished partitions

- Light steel: the frame and the outer panel should be in the construction site processing, but also brush at least 2 times the putty +2 paint. Finished partition: mainly in the factory processing, in the field just assembled only.

Send your message to us

Ceiling Channel Suspension System Main Channel and Furring Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords