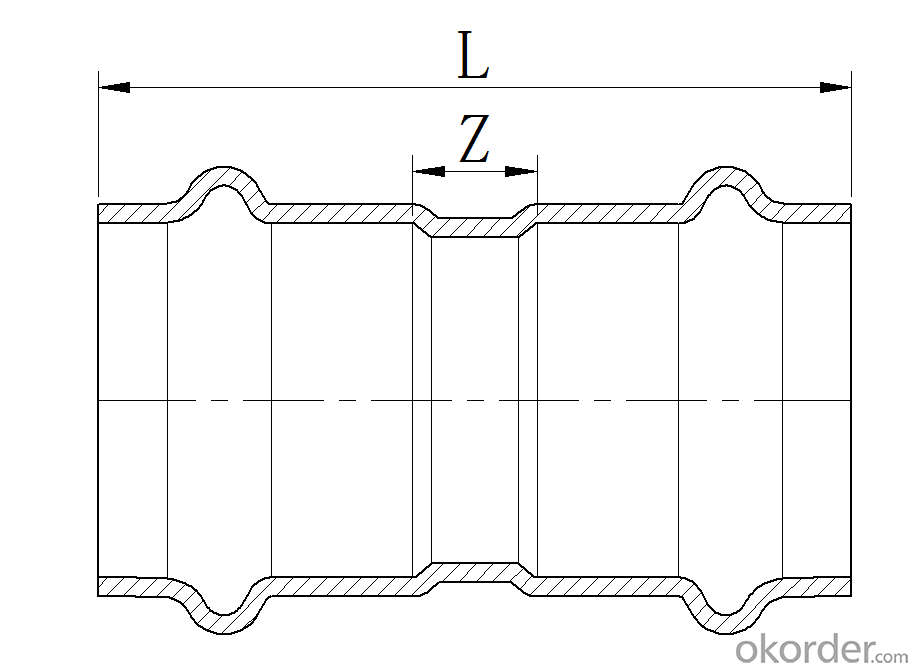

Stainless Steel Sanitary Fitting Coupling 76.1mm V Profile 304

- Loading Port:

- Huangpu

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

WELCOME to visit our stainless steel pipeline products here(^_^)

Press fitting system joins pipe without welding or bolting. The components fit by crimping through the use of a special pressing tool. An O-ring that is inserted in the fitting ends of the pipe ensures a leak-proof connection. Press fitting system is the trend of pipeline industry. It is widely used in cold and hot water supply, heating supply, fire protection, medicinal gas, industrial petroleum pipeline system etc.

For the size, now we have 3 series:

1. Out diameters: 16.0, 20.0, 25.4, 32.0, 40.0, 50.8, 63.5, 76.1, 88.9, 108.0 (GB/T 19228.2-2011)

2. Out diameters: 15.88, 22.22, 28.58, 34.0, 42.7, 48.6, 76.1, 88.9, 101.6 (JIS G3448-1980)

3. Out diameters: 15, 18, 22, 28, 35, 42, 54, 76.1, 88.9, 108 (EN 10312:2002)

Technical information:

-- Material: Stainless steel 304 and 316L available.

-- Max working pressure 1.6MPa (equal to 232 psi), testing water pressure: 2.5MPa (equal to 362.5psi).

-- Working temperature from -20 to 110 degree centigrade (with Chlorinated butyl rubber O ring),

-- Suit medium: Cold water, hot water, compressed air, gas, oil etc

The product features as below:

1, thin wall stainless steel pipe could last for 70 years, it is the same life time with normal buildings.

2, no smell, no rusty.

3, recycle material

4, avoid welding, avoid fire dangerous.

Contact us for more details!

- Q: i think i may be pregnant..if my boss fires me or lays me off after he finds out can i get him in any trouble? what if he waits till after matertinity leave

- a constant beeping sound like eggggg eggggggg!!! GOOD LUCK!!!

- Q: How many people dress thier dogs up? Why do you do it? What do you dress them up in?Do you do it for fun or for safetey and warmth?Why do you do it?Do you think its cool or cute?and also do you dress up only special breeds of dogs?DO you think its good for the dogs?Why do people do it?And last but not least how many people dress thier dogs up if so what kind of dog and what kinda of clothes do you put on them? And why?

- The two bolts that look alike go through the two holes after the bracket is placed on the frame. The swivel headed bolt is used to secure the lock once you place it in the mount. Tighten the bolt with the swivel parallel to the bolt until there is no play in the bolt and then fold the swivel until it is at a 45 degree angle. It will tighten up and add pressure in order to clamp on the lock and keep it from popping out of the mount if you hit a bump. Good luck! Eric

- Q: I am the most expensive in town, but it's also true that I offer cageless boarding, an over 400 square feet play room, free 2 walks a day and am a dog trainer/behavior consultant that is pet first aid certified. I also only accept 2-3 dogs so they can get the attention they deserve. Have toys, swimming pool for dogs, and offer 24/7 supervision. Just checking on thoughts for my pricing, thanks!

- The models used to predict head loss have no physical basis, should you be in the turbulent flow regime. They are curve-fitting to standardized experimental results of controlled experiments. Many flow conditions of turbulence are difficult to predict.

- Q: my microlab m-666 (2:1) has a great ammount of trible out put. my brother has a speaker of ALTEC LANSING ACS45.1, it gives a heavenly BASS output(this speaker is celibrating its 15 year birthday!!!!!) but the bad newz is my microlab has a disgusting bass out put. expert sez that my trible is WAY to0 much. so balencing the trible might do it!! but it has no trible EQULIZR!!!!but, if i make my writing paper into an elephant trunk and insert it to the SUBWOOFER output, then it sounds ALTEC lansing. but still, the out put is not enuff!! still it doesn't make an earth quake to our house. if ne 1 undrstand my prob, plz HELP me( amplifire won't help)and dont b funny, this is serious, this is my first speaker!

- Each situation is unique and if one is faced with an employment termination situation, it is best to contact a qualified lawyer/counsel. Generally speaking under at will employment contracts, an employee can be fired for any or no reason. However, depending on the state / federal jurisdiction and / or other conditions, it may be unlawful to discriminate based on factors such as: Race, Color, Religion, National origin, Age (40 and over), Sex, Sexual orientation, Gender identity, Disability status, Veteran status, and/or Genetic Information. You will notice that the condition of being a smoke or non-smoker is not listed as a factor. So a smoker can expect little legal protection for just being a smoker! People with STD or infection may fall under disability and therefore may have legal protection.

- Q: what is elastomer?what is resin?

- The most dangerous part of a storm is the wind. Second is flooding if it rains enough for it to occur. Relax and enjoy nature's light show. The odds of being struck by lightning are very low. The purpose of the lightning rod is not to avoid or prevent lightning but to attract it. The idea is to control where the lightning goes rather than having it strike somewhere random. There is a slight danger of injury if you're in contact with appliances when the lightning strikes nearby such as upon power lines. Just avoid such contact during the storm.

- Q: What are the differences between hydraulic couplings and fittings and elbows?

- 1. The joint is a bridge between the hydraulic pipe joint and the equipment. The elbow is to change the direction of pipe fittings, their division of labor is not the same.2 、 hydraulic pipe joint hydraulic system, connect between the high-pressure oil pipe and the high-pressure tubing parts. Divided into: hydraulic hose, high pressure ball valves, quick couplings, odd intention ferrule type pipe joint, welded pipe joints, high-pressure hose, transition pipe joint, sleeve type pipe joint, three way pipe joint, non-standard pipe joint, flared type tube fittings, pipe joint, rotary angle tube fittings, quick connector, stainless steel pipe fittings, copper fittings.

- Q: Can someone translate this to english (from korean)?

- Burst implies a domestic water pipe, hot or cold, so the answer will be based on that implication. Determine the size of the pipe. Likely it will be either 1/2 or 3/4, likely copper. Determine the extent of the burst. If from a freeze, likely it will be a split along the length of the pipe, anything from a few inches to (rarely) over a foot. Go to your local big-box store and purchase a length of PEX of the appropriate size that is at least six inches longer than the damaged area. PEX usually comes in short pre-cut lengths or in a 100' or 200' roll. A pre-cut length will do it in most case. Purchase two Shark-Bite couplings to match. If you do not have a pipe-cutter, for what you will save from calling a plumber, you can afford to buy one, and a good one at that. The PEX can be cut with a sharp kitchen knife. Cut out the bad section + a little bit from each end - 3 or so. Cut the PEX to match the gap, less about 1/2 on either side. Install the fittings - left end fitting to copper; PEX; right end fitting to PEX; fitting to copper. Be sure to bottom the fittings as you go. Less than $40 including a Ridgid pipe cutter. Less than $20 otherwise. It is not rocket science, all you need is patience and a little bit of hand-strength. Ask the person in the store to show you how to use the cutter, and even how to use the fittings. Once you learn, you will be prepared for the next time. NOTE: If you use a hack-saw to cut the pipe ILO a tubing cutter, be sure to cut slowly and not force the pipe out-of-round. Cut all the way through - don't be tempted to break off the last bit. Clean the rough edges with a file and get the marl (cutting waste) out as best you can. In either case, when you turn the water back on, run a hose or tub fixture for at least a minute to get any displaced particles out. Good luck with it.

- Q: I heard once it was 68% or something.

- Contact a lawyer anyway and ask for advice on what to do and after that the court house should be able to appoint you a lawyer but that might just be if you are arrested another thing u can do is to report it to your company director of HR (human resources) good luck

- Q: Think of how much air the drivers can get if they hit a speed bump at 200MPH. It would be a challenge for the driver to make all of the yellow lights.

- If you have a pipe cutter, you can remove the section, that is, if you can live without that half-inch. If you're replacing it with another compression fitting, you would do well to place it on a section of the pipe that isn't marred up or corroded. Personally, I can't stand the compression fittings. I'd rather sweat the pipe and fixtures in place. You might consider that. It's well worth it, if you do minor plumbing like this, to spent the few bucks and get a pipe cutter, it gives a smooth cut and can fit in some really tight places.

- Q: Will the alarm still go off

- 7018 isn't well suited for vertical-down root passes, due to it's heavy, sluggish, fast-freezing slag. The thick heavy slag tend to cause inclusions when trying to fill an open root gap on pipe. It's traditional to use 601/6011 for the root pass, because it performs far better for open roots, 7018 is used for the filler passes. It's also traditional to use TIG for the root which generally produces far better root quality than stick welding. the root pass is critical because the greatest stress is on the inside of the pipe. If welding is absolutely your only option the best quality will be had by TIG welding the root, instead of 6010/6011. I would strongly recommed TIG roots. It is quite difficult to get a consistent root pass on small pipes. With pipe welding quality prep work and accurate fit-up are extremely important. Furthermore for small pipes, using screw-on fittings will likely save you labor in the long run. Not to mention being probably the more reliable option. Using a pipe vice and a pipe threading tool takes less time and skill than properly done fitting and welding. You might also consider brazing with slip-on joints. Brazing is faster, easier, and generally less prone to leaks than welding.

Send your message to us

Stainless Steel Sanitary Fitting Coupling 76.1mm V Profile 304

- Loading Port:

- Huangpu

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords