Stainless Steel Filter Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

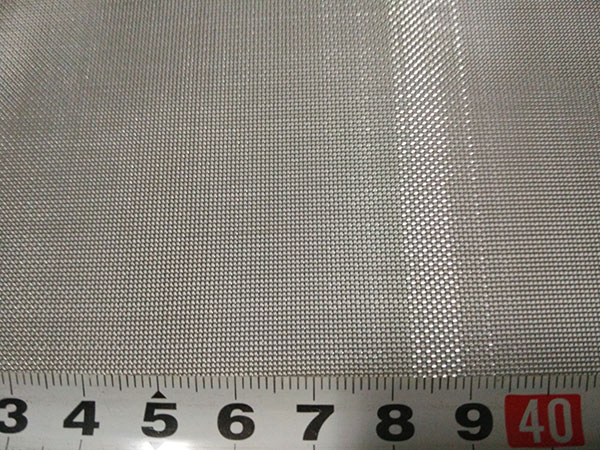

40 Mesh Stainless Steel Wire Mesh

Material: 304 stainless steel wire

Wire Diameter: 0.15 mm

Mesh: 40 mesh

Width: 1m

Length: 30 m/Roll

Popular Specifications Of Stainless Steel Wire Mesh

| stainless steel wire specification(Plain weave) | |||

| mesh | wire dia(mm) | Opening(mm) | Material(Alsl) |

| 7 | 1 | 2.63 | 304 or 316 |

| 10 | 0.6 | 0.94 | 304 or 316 |

| 12 | 0.5 | 1.62 | 304 or 316 |

| 16 | 0.4 | 1.09 | 304 or 316 |

| 16 | 0.35 | 1.24 | 304 or 316 |

| 18 | 0.35 | 1.06 | 304 or 316 |

| 20 | 0.4 | 0.87 | 304 or 316 |

| 24 | 0.26 | 0.8 | 304 or 316 |

| 30 | 0.3 | 0.55 | 304 or 316 |

| 35 | 0.17 | 0.56 | 304 or 316 |

| 40 | 0.23 | 0.4 | 304 or 316 |

| 50 | 0.2 | 0.31 | 304 or 316 |

| 60 | 0.15 | 0.27 | 304 or 316 |

| 70 | 0.12 | 0.24 | 304 or 316 |

- Q: Is steel wire mesh resistant to pests?

- Steel wire mesh is indeed resistant to pests. Due to its tightly woven structure, pests like insects or rodents find it challenging to penetrate through. Consequently, it serves as a highly effective obstacle against unwelcome intruders in diverse scenarios. It proves valuable in safeguarding gardens from pests, ensuring the protection of vents and windows from insects, and preventing the entry of small animals into properties. Moreover, steel wire mesh exhibits remarkable durability and can endure various environmental conditions, thus providing a lasting solution for pest control.

- Q: How does steel wire mesh differ from other types of wire mesh?

- The primary distinction between steel wire mesh and other wire mesh types lies in its composition and unique qualities. Unlike aluminum or copper wire mesh, steel wire mesh is crafted from steel, an alloy of iron and carbon. This grants it exceptional strength and durability in comparison to alternative wire mesh options. Steel wire mesh is renowned for its remarkable tensile strength, enabling it to withstand substantial loads and resist deformation when subjected to pressure. Additionally, it exhibits exceptional resistance to corrosion, rendering it suitable for outdoor applications that frequently encounter moisture or chemicals. Moreover, steel wire mesh possesses excellent heat resistance, making it well-suited for use in high-temperature environments. Another noteworthy difference pertains to the array of weaves accessible in steel wire mesh. The most prevalent weaves include plain weave, twill weave, and Dutch weave. These distinct weaves offer varying levels of permeability, strength, and filtration capabilities, enabling steel wire mesh to be employed in a wide array of applications such as filtration, reinforcement, containment, and security. Additionally, steel wire mesh is readily available in diverse wire diameters and mesh sizes, providing versatility to accommodate specific application requirements. It can be effortlessly tailored to suit precise needs, whether it entails heavy-duty industrial utilization or more delicate purposes such as sieving or decorative applications. In conclusion, steel wire mesh distinguishes itself from other wire mesh variants due to its superior strength, durability, corrosion resistance, heat resistance, and versatility in terms of weave patterns, wire diameters, and mesh sizes. These exceptional attributes render it an ideal choice for a broad spectrum of industrial, commercial, and residential applications.

- Q: Is steel wire mesh suitable for poultry farming?

- Indeed, poultry farming finds steel wire mesh to be a fitting option. This material proves itself as both durable and robust, effectively ensuring the containment and protection of poultry. It establishes a secure perimeter, preventing the fowl from either escaping or falling prey to predators. Furthermore, steel wire mesh allows for the necessary ventilation and airflow within the poultry enclosure, thereby maintaining a healthy environment for the birds. Moreover, its easy maintenance and cleaning characteristics make it a practical choice for poultry farming. In summary, steel wire mesh emerges as a dependable and efficient choice when it comes to constructing safe and secure enclosures for poultry farming.

- Q: How is steel wire mesh used in reinforcement of pharmaceutical and healthcare facilities?

- Steel wire mesh is commonly used in the reinforcement of pharmaceutical and healthcare facilities to provide structural support and enhance the safety and durability of the building. It is used in various applications such as reinforcing concrete floors, walls, and ceilings, as well as in the construction of storage areas, laboratories, and cleanrooms. The steel wire mesh helps to prevent the formation of cracks, increase load-bearing capacity, and ensure the overall integrity of the facility, thus ensuring a safe environment for pharmaceutical and healthcare operations.

- Q: How is steel wire mesh used in security systems?

- Due to its durability and strength, steel wire mesh is commonly used in security systems. It is frequently employed to construct fences, barriers, and enclosures that provide a high level of security. The tightly woven mesh design acts as a physical deterrent, making it challenging for intruders to penetrate or climb over. In security systems, steel wire mesh is typically installed in sensitive areas like airports, government buildings, prisons, and industrial facilities. It can secure perimeters, windows, doors, and even rooftops. The mesh can be customized to meet specific requirements, allowing for flexibility in design and installation. Steel wire mesh also offers excellent visibility, enabling security personnel to effectively monitor their surroundings. It does not obstruct views or compromise natural lighting, ensuring a clear line of sight. Additionally, the mesh can be integrated with other security components such as surveillance cameras, motion sensors, and alarms to create a comprehensive security system. One of the main advantages of steel wire mesh in security systems is its resistance to cutting and tampering. The strong and rigid nature of the steel wires makes it extremely difficult to manipulate or break through, effectively deterring forced entry or vandalism. Furthermore, steel wire mesh is highly resistant to corrosion and weathering, making it suitable for both indoor and outdoor security applications. It can withstand harsh environmental conditions, including extreme temperatures, heavy rain, and UV exposure, without deteriorating or losing its effectiveness. In conclusion, steel wire mesh is a versatile and reliable component in security systems. Its strength, durability, visibility, and resistance to tampering make it an ideal choice for enhancing security and protecting valuable assets.

- Q: Can steel wire mesh be used for window and door screens?

- Yes, steel wire mesh can be used for window and door screens. It is a durable and strong material that provides protection against insects and other unwanted elements while allowing airflow and visibility.

- Q: Is steel wire mesh resistant to static electricity?

- Yes, steel wire mesh is generally resistant to static electricity due to its conductive properties.

- Q: What are the different mesh shapes available for steel wire mesh?

- Steel wire mesh comes in a variety of shapes, each designed to meet different application requirements. Some of the most common mesh shapes available for steel wire mesh include: 1. Square Mesh: This is the most basic and widely used shape. The wires are arranged in a square pattern, with equal spacing between each wire. Square mesh is versatile and can be used for various applications ranging from filtration to reinforcement. 2. Rectangular Mesh: Similar to square mesh, rectangular mesh has wires arranged in a rectangular pattern. This shape is often used in applications where a specific width or aspect ratio is required. 3. Hexagonal Mesh: Also known as hex mesh or chicken wire, this shape features wires woven in a hexagonal pattern. Hexagonal mesh is commonly used for fencing, poultry enclosures, and erosion control due to its flexibility and easy installation. 4. Diamond Mesh: Diamond mesh is created by weaving wires in a diamond-shaped pattern. It is often used in security applications, such as window or door screens, as well as in construction and industrial settings for reinforcement or as a barrier for small objects. 5. Welded Mesh: As the name suggests, welded mesh is made by welding intersecting wires together at their junctions. This results in a strong and durable mesh that is commonly used in construction, industrial, and agricultural applications. 6. Expanded Mesh: Expanded mesh is created by cutting and stretching a sheet of metal, resulting in a mesh with diamond-shaped openings. This shape provides excellent strength and rigidity, making it suitable for walkways, platforms, and fencing. 7. Twilled Mesh: Twilled mesh is characterized by wires that are woven in a twill pattern, creating a diagonal appearance. This mesh shape is often used in filtration applications, as it provides a higher level of filtration efficiency compared to square or rectangular mesh. These are just a few examples of the different mesh shapes available for steel wire mesh. The selection of a specific shape depends on the intended application, desired strength, flexibility, and other requirements.

- Q: Is steel wire mesh suitable for waste management applications?

- Steel wire mesh proves to be a suitable option for waste management purposes. Its suitability is rooted in a range of advantages it offers. Firstly, steel wire mesh is exceptionally durable and can endure heavy loads and harsh surroundings. This quality makes it ideal for waste management applications, as it may come into contact with different waste materials and potentially corrosive substances. Additionally, steel wire mesh is resistant to breakage and does not degrade easily, ensuring a long lifespan even in high-stress scenarios. Secondly, the versatility of steel wire mesh allows for customization to meet specific waste management requirements. It can be shaped and sized as needed, enabling the construction of waste bins, containers, and enclosures that can accommodate a variety of waste materials. The mesh design also promotes easy visibility and airflow, which are essential for waste management processes like sorting and composting. Moreover, steel wire mesh is easy to clean and maintain, ensuring hygiene in waste management operations. A simple hosing down or pressure washing can eliminate any dirt or residue, minimizing the risk of contamination or unpleasant odors. Furthermore, steel wire mesh is cost-effective. Compared to alternatives such as solid metal or plastic, it is relatively inexpensive. This affordability makes it a practical choice for waste management facilities that require a large quantity of waste bins or enclosures. In summary, the durability, versatility, cleanliness, and cost-effectiveness of steel wire mesh make it a fitting material for waste management applications. It can endure challenging environments, accommodate diverse waste materials, and offer an efficient and hygienic solution for waste containment and handling.

- Q: How is steel wire mesh used in reinforcement of beams?

- To improve the strength and durability of beams, steel wire mesh is commonly utilized for reinforcement. This mesh consists of interconnected steel wires that form a grid-like pattern, which is then embedded within the concrete of the beam. This reinforcement technique, known as wire mesh reinforcement, aids in distributing the load evenly across the beam, thereby reducing the risk of cracking and failure when subjected to heavy loads. The steel wire mesh functions as reinforcement by offering additional tensile strength to the beam. While concrete is strong under compression, it is relatively weak in tension. By introducing the wire mesh, the tensile forces are transferred to the mesh, enabling the concrete to primarily withstand compressive forces. This combination of materials produces a reinforced beam that possesses the capacity to withstand both compression and tension forces, significantly increasing its ability to bear loads. During the construction process, the steel wire mesh is typically strategically positioned within the cross-section of the beam. It is crucial to ensure that the mesh remains at an optimal depth within the concrete to effectively reinforce the beam. This is often accomplished by utilizing supports or chairs to secure the mesh in place during concrete pouring and initial curing stages. In addition to providing strength, steel wire mesh also assists in controlling cracking caused by temperature changes or shrinkage in the concrete. By distributing forces more uniformly, the mesh acts as a barrier, preventing cracks from spreading and reducing their size and extent. This is particularly critical in beams, as cracks have the potential to compromise the structural integrity of the beam and result in failure. In conclusion, steel wire mesh plays a crucial role in enhancing the strength and durability of beams. By offering additional tensile strength, it enables the concrete to resist tension forces and prevents cracking, ultimately ensuring the beam's ability to bear heavy loads and maintain its structural integrity over an extended period.

Send your message to us

Stainless Steel Filter Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords