Stainless Steel Fermenter With CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

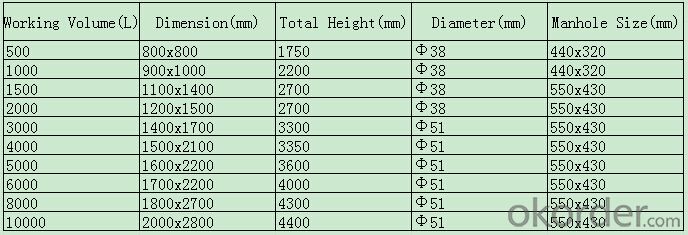

Specifications

Technical Data:

- Q: I have a Weil McLain 568 boiler. I need to locate the terminal block in order to connect the C wire for a new wifi thermostat. I don't know how to locate the terminal block. Any suggestions?

- the okorder /... your search box is your friend and these simple few words brought this up ++ weil mc lain 568 boiler schematic ++ change the words and get instant and multiple helpful sites for your projects ....

- Q: Plz explain the difference and applications for both boiler.If any pictures available means kindly send .in

- There are fire tube boilers where the products of combustion travel through the tubes to heat the water. These are sometime called Scotch marine boiler. There are tube type boilers where the water is in the tubes but the tubes are connected at top and bottom by drums. The bottom drum is called the mud drum and the top is the steam drum where the water level in the boiler is maintained and the steam is separated from the water. The coil type boiler is a special version of the water tube boiler in that the tubes are formed in a spiral. The links below will give some additional information.

- Q: What is the kiln? How is it different from the boiler?

- The history of thousands of years of human ceramics burning, has accumulated a wealth of kiln style and experience.

- Q: i repaired a broken heating water pipe. how do i bleed my oil fired system it is base board heat

- You should have a small valve at each radiator location. Depending upon your valve you will need a small key designed to fit the part you turn. Follow the system in order of the radiators and open each valve one at a time. You will usually get a hissing sound as the air escapes...you may also hear gurgling of water at this time. When you get a steady stream of water only, then you can close the valve and move on to the next radiator. When you complete the cycle, you can try to bleed the highest radiator again. I take a small cup with me to catch the water, as I usually get about that much after three radiators. Another thing you will need to do is make sure your expansion tank is not waterlogged. If this is an old system, it will be in the highest point of the system. There should be two valves to drain the tank. First close the valve that is connected to the loop of hot water pipe. Then, open up the drain valve to the tank. Depending upon how much water is in the tank, it may take a while to drain it. When water has stoppedd flowing from the tank, reverse the process by closing the drain line, and then re-opening the valve that is connected to the loop. You will hear water rush into the tank, that is ok. when this is completed you should then go around and bleed each radiator. Sometime, as you bleed the radiator, the pressure drops in the system, and you will get nothing coming out of the radiator...try again later when the pressure is again up to operating pressure. When the boiler has been on for a while, you will probably get best results on bleeding. We replaced are boiler two years ago, so the expansion tank is at the boiler location, plus we installed an in line bleeder at the boiler. We rarely bleed the system anymore.

- Q: I have just been quoted ?3096 for a new greenstar camray 12/18 utility boiler to be installed,along with a new central heating programmer,a remote room stat and a magnaclean water filter.also the fire valve is being relocated outside.This is the complete price including VAT is this too much? it seems quite high to me! Thanks in advance

- Firstly don't go near worcester oil boilers. I have heard of problems with them. The parts excluding any copper piping and I have just quoted for a typical through the wall balance flue comes in at ?1500. That means ?1500 profit. Nice work if you can get it. Probably take only 2 days to install. You might want to consider Air Source heat pump. Will be as cheap to run as a natural gas condensing boiler. ?1200 off OKorder for a 12kw one should do you should last 10-15 years and need no servicing. No oil tank or deliveries to worry about.

- Q: In the morning, it takes my gas steam boiler sometime to reach the desired thermostat temp. i.e. it goes down to 60 degrees at 11pm and it turns back on at 7am to 68 degrees. Today it's 34 degrees out and it's been recycling when the pressure gauge in PSI reaches about 2.5lbs. it shuts down for about 5 minutes and when the pressure drops to about 1lb it kicks back on. So right now it's 8:45am and after being on since 7am the temp in the house is only 66degrees. The house is a dutch colonial 3 floors and a basement..about 1800sq. feet. it's getting there but Its cold out and my house is pretty air tight..new windows etc insulation is good. There is the limit control that is set to .1......(cut in cut out)....can I raise that so that the unit will shut down at a higher PSI..like 5 instead od 2.5?

- Any Component Of Your MotherBoard Has A Failure In It, Go To Your Nearest Computer Shop

- Q: Would you recommend me replacing my baxi back boiler with a combi ? I am having no problems with it but it is about 30 years old and I am about to start decorating so thought this my be a good time to get the job done . If so what type of combi boiler should I go for ? Is it a valiant ?????

- The water pressure wil be the same as your hot and cold water is now. But if the shower head is higher than the top of the boiler, you could lose pressure on you hot water to the mixer valve.

- Q: This isn't an Engineering Question per say, but you mechanical engineers might be able to help me with this. If there is any Power Engineers out there, this is right down your alley.I would like to know if im correct in comparing Show Assembled Boilers vs. Packaged Boilers.I know there is more to the actual boilers then this, plus advantages and disadvantages, but i just want to know the actual difference between the terms.Packaged Boiler - Pre-designed, pre-built packaged boiler that is built at a shop and transported as 1 unit.Shop Assembled Boiler - Main difference is that These boilers are built to exact customer specifications as opposed to the customer picking out a pre-designed packaged boiler?Is this correct?

- Pretty much the size of it.

- Q: I got a letter in the mail (and so did my 4 other roommates) stating that we owe our landlord about $10,000 because she believes the boiler broke because of our negligent behavior. The boiler cracked and broke after 3 years and she is saying it is because we turned the heat off for days at a time or turned the heat at or above 80 degrees f. This is not true, nor does she have any proof that we did that. Even if she did, there is nothing in the lease about what temperature the house must be kept at. Where should we go from here? My roommate's father is a lawyer and is currently writing a letter back but will we have to go to court etc?Thank you for your time

- Ignore the letters. Your landlord is totally responsible for the boiler. The landlord is obviously a creep. Sometimes you get one who expects you to pay for every repair maintenance job but the legal responsibility is on the landord. If he takes you to court, he will lose. His argument is ridiculous.He placed your safety and well-being in jeopardy by not maintaining the property. Stick that one to him. PS: Boilers don't break this way, it is RIDICULOUS! Thumb me down all you want, but I am right.

- Q: banking a boiler;putting it on natural draught;steaming a boiler

- There is a control panel with every boiler which regulates the amount of fuel (which means regulating the steam), air blower, etc. Also there are mountings and valves and pressure indicators. Its easy.

Send your message to us

Stainless Steel Fermenter With CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords