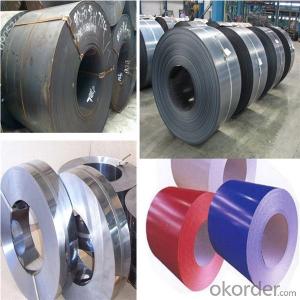

Stainless Steel Coil 201, 202,301, 304, 316,304L,316L,309,410,430

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 300 Series | Standard: | JIS,AISI,GB | Length: | as customers' requested |

| Thickness: | 0.1-120mm | Width: | 1000-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | 309S | Type: | Coil |

| Application: | petroleum refining | Certification: | SGS, ISO | Color: | natural color |

| Packing: | Standard export seaworthy packing or according to your requirements | Available Finish: | 2B/BA/8K/No.4/SB/HL | Edge: | slit edge and mill edge |

| Features: | accurate dimensions | Manufacture technology: | cold drawn,pickling, hot rolled and cold rolled | Quality: | high quality 201, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

| Stock: | Always in stock | Item: | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as customer's requirement ASTM 309S Stainless Steel Coil |

| Delivery Detail: | In 15 days |

Specifications

201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil

Width:1000-2000mm

Thickness: 0.1-120mm

Quality:High quality

Product Description

ASTM 309S Stainless Steel Coil

Thickness:0.1-120mm

Width:1000-2000mm

Length: As required

Typical physical properties for stainless steel coil

Grade | Chemical composition | ||||||

C | Si | Mn | P | S | Ni | Cr | |

% | % | % | % | % | % | % | |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.030 | 12.00-15.00 | 22.00-24.00 |

Item | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201, 202,301, 304,316,304L,316L,309,410,430 |

Surface | NO.1,2B, mirror finish,4K,8K,Hairline finish |

Thickness | 0.1-120mm |

Width | 1000-2000mm |

Price term | FOB,CFR,CIF,CNF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

- Q: What are the different coil cutting methods used for steel coils?

- There are several different coil cutting methods used for steel coils, including slitting, shearing, and laser cutting. Slitting involves using circular blades to cut the coil into narrower strips. Shearing involves using straight blades to cut the coil into desired lengths or shapes. Laser cutting, on the other hand, uses a high-powered laser beam to precisely cut the steel coil into specific shapes or patterns. Each method offers its own advantages and is chosen based on the desired outcome and requirements of the steel coil cutting process.

- Q: I have a Nike SQ Sumo 21 degree and it is a steel shaft. I hit the ball very high with this club and I lose distance. I don't hit any of my other clubs high it's just this one. Is it because of the steel shaft or is it the club? Help please.

- if you are a good player they say steel shaft is better. more consistent. I prefer graphite its lighter and I can flip my wrists easier.

- Q: Why is steel so important? How does it help us in everyday life?

- steel comes from iron. Iron is a natural resource and is abundent in nature. so being able to turn it into steel means it can be used for alllll sorts of things! from buildings, cars, piping and tubes, to washing machines, appliances and many other things. its used in our everyday life and is a great, strong material.

- Q: What are the common international standards for steel coils?

- The common international standards for steel coils include ASTM A36/A36M, ASTM A572/A572M, ASTM A283/A283M, ASTM A516/A516M, and EN 10025-2. These standards specify the requirements for the chemical composition, mechanical properties, and dimensions of steel coils used in various industries worldwide.

- Q: How do steel coils perform in high-pressure applications?

- Steel coils perform well in high-pressure applications due to their inherent strength and durability. The high tensile strength of steel allows it to withstand the intense pressure without deformation or failure. Additionally, steel coils can be manufactured to precise specifications, ensuring they can handle the specific pressure requirements of the application. Overall, steel coils are a reliable and efficient choice for high-pressure applications.

- Q: What are the different surface finishes available for steel coils?

- Some of the different surface finishes available for steel coils include hot-dip galvanized, galvannealed, electro-galvanized, and plain.

- Q: Moravia’s coal and steel industries face challenges because they _____. a.do not run efficientlyb.have run out of resourcesc.have a declining work forced.have not privatized

- As someone who have lived in northern Moravia at industrial steel and coal city of Ostrava, the closest point is b), but it is questionable. I am not sure how to compare efficiency of largest steel mill in Czech Republic in comparison to China which is the biggest exporter, but Czech steel factories were modernized and run more efficient that 25-35 years ago, and been privatized and owned by Mittal. The workforce had been shrinking, so not exactly sure what that c is pointing to (aging of workforce, size of it, or quality). Northern Moravia is a part of larger coal basin that extend to Poland with large coal deposits. This was foundation for the steel industry in the 1800's together with large ore deposits that was mined in proximity of the Beskidy mountains less than 25 miles from Ostrava. The iron ore mines had been depleted for several decades, and since the late 70's when communists run the country, they were already importing Soviet iron ore. Coal mining within city of Ostrava cased to exist in the 1990's due environmental issues, and also cost. The mines were getting deeper and more costly to operate and there is no more mining within Ostrava. Couple mines are still in operation in Karvina county which is next to Ostrava. Currently the coal deposits south of the city were not opened due environmental issue which would mean destruction of third largest mountain range in the country. Therefore, my conclusion is is b, as the ore and coal resources been shrinking. The biggest challenge not mentioned here is of course competition from Russia, Ukraine, and China, which can produce steel much cheaper.

- Q: What are the factors that affect the quality of steel coils?

- There are several factors that can affect the quality of steel coils. Some of the key factors include the selection and quality of raw materials used, the manufacturing processes employed, the level of expertise and skill of the workforce, the adherence to strict quality control measures, and the overall condition and maintenance of the equipment used in the production process. Additionally, external factors such as environmental conditions and transportation methods can also impact the quality of steel coils.

- Q: how do i quinch steel? i heard instead of water oil will actually make it harder... wat ways are best for wat steels? and how do i tell wat kind of steel i have?... i will be doin this with my poket knife..

- boy what a though question ! let me explain. when you rapidly cool a steel from high temperatures(depending on steel type) with water or oil or other means , it is called quenching. it depends on the steel type to say if it is better to quench it with oil or water but basically in water you will have a harder steel rather than oil. for some steels if you do this you will ruin it's properties ! you can't totally tell what kind of steel do you have until you get it analyzed with Quantometer analyzer with a pocket knife it is more like an estimation and it can't be trust able generally if you can scratch the steel with your knife it means it is not a hard steel and it might not be expensive. I hope that helps but for more information i need to know more !

- Q: I want a stainless steel refrigerator that doesn't leave fingerprints and I'm looking on Lowe's website but they have too many choices and i don't have a clue what they are. The have stainless, stainless look, stainless steel, monochromatic satina, and monochromatic stainless steel. Can anyone tell me what the heck those mean? lol

- Stainless Look vs Stainless in refrigerators usually refers to true Stainless Steel versus Satina. There's pluses and minuses both ways actually. With true Stainless, you have the exact match to the rest of the kitchen (because Satina is only used on refrigeration), but it is more prone to fingerprints, and is not magnetic. The Satina finish has a good look when not directly near a Stainless appliance, and does not show fingerprints and will accept magnets, but is not an exact match to stainless. My usual recommendation is that if you have a kitchen full of Stainless products, stick with the true Stainless Steel. If the refrigerator is more isolated, or is the only thing you want to have a Stainless look, you may want to consider Satina. If you put a lot of magnets on the refrigerator, I'd also recommend to go Satina. And since you don't want fingerprints, the Satina steel might come to your liking.

Send your message to us

Stainless Steel Coil 201, 202,301, 304, 316,304L,316L,309,410,430

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords