Stainless steel 316 polished round bar H11 tolerance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

2.5-500

Length:

6000

Net Weight:

1-5T

Stainless steel bars,profiles,beams

Product Information:

1) Product feature:

| 1. Product: | Stainless steel 316 polished round bar, 316 stainless steel bright round bar |

| 2. Steel type: | AISI 316 |

| 3. Standard: | ASTM A276, ASTM A484 |

| 4. Diameter: | From Ø1/4'' to Ø16'' ( Diameter: 6mm~400mm ) |

| Such as Ø1'', Ø2'', Ø2.5'', Ø3'', Ø3.5'', Ø4'', Ø4.5'', Ø4.5'', Ø5'',Ø6'', Ø7'', Ø8'' | |

| 5. Length: | 1~ 8meters |

| * Bright: peeled & polished, CNC machined, centreless grinding | |

| 6. Surface: | * Black |

| 7. Diameter tolerance: | H9, H11, H13, K9, K11, K13 etc…as per clients’ request |

| 8. Length tolerance: | 0/+50mm |

| 9. Finishing: | Solution treated |

| 10. Feature of 316L: | Addition of Molybdenum prevents specific forms of corrosion. Also known as "marine grade" |

| 11. Mechanical property: | T.S.: ≥515Mpa, Y.S.: ≥205Mpa, EL: ≥40%, Ruduction of area: ≥50% |

| 12. Application: | Shipbuilding industry, marine shaft, propeller shaft, transmission shaft |

| bolt & nuts, machine-made industry, food industry, paper mill equipment. | |

| 13. Delivery time | Generally within 15~20 days upon receipt the PO, as per the q’ty. |

| 14. Certificate: | ISO, BV, TUV, SGS, mill test certificate |

| 15. Package: | Good quality & fumigated wooden box, which can better protect the bars. ( See pictures below ) |

| 16. Experience:: | * Specialized in producing SS 316L round bar for propeller shaft purpose; |

| * Have a close connection with overseas shipyards , such as Indonesia, Thailand, Philippines, | |

| Singapore, Brazil, Canada etc., so have much experience in this field. |

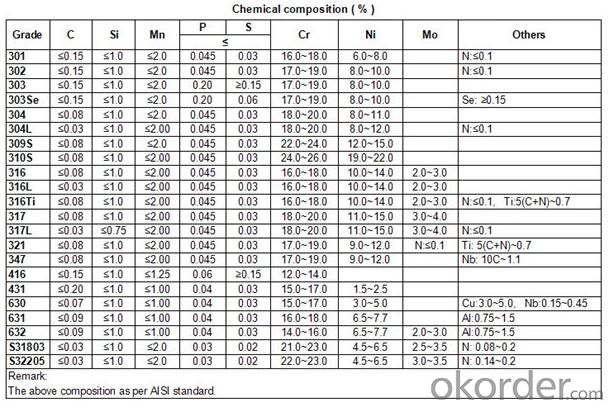

2) Chemical composition:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| 316 | ASTM A276 | ≤0.08 | ≤1.0 | ≤2.00 | ≤0.045 | ≤0.03 | 16.0~18.0 | 10.0~14.0 | 2.0~3.0 |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: What's the price of 202 stainless steel round bar?

- In practical application, the steel which is often corroded by weak corrosive medium is called stainless steel, and the steel which is resistant to chemical medium is called acid resisting steel. Because of the difference in chemical composition between the two, the former is not necessarily resistant to chemical medium corrosion, while the latter is generally stainless. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel

- Q: Can stainless steel bars be used in cryogenic storage tanks?

- Yes, stainless steel bars can be used in cryogenic storage tanks. Stainless steel is known for its excellent resistance to low temperatures and is commonly used in cryogenic applications. It can withstand the extreme cold temperatures required for cryogenic storage without losing its structural integrity or deteriorating. Stainless steel bars are often used in the construction of cryogenic storage tanks due to their high strength, corrosion resistance, and ability to maintain their mechanical properties at low temperatures. Additionally, stainless steel has a low thermal conductivity, which helps to minimize heat transfer between the stored contents and the external environment. This makes stainless steel bars a suitable and reliable choice for use in cryogenic storage tanks.

- Q: Do stainless steel bars have good resistance to scaling?

- Stainless steel bars possess excellent resistance to scaling, as they do not form oxide layers on their surface when exposed to high temperatures. This resistance is attributed to the presence of a minimum of 10.5% chromium in stainless steel, which creates a protective layer of chromium oxide. This layer serves as a barrier, effectively preventing any further oxidation or scaling. Furthermore, stainless steel bars can be alloyed with other elements like nickel and molybdenum, further boosting their resistance to scaling in high-temperature settings. As a result, stainless steel bars are extensively utilized in critical applications that demand exceptional scaling resistance, such as high-temperature environments, furnaces, and heat exchangers.

- Q: What are the applications of round stainless steel bars?

- Round stainless steel bars have a wide range of applications across various industries. Some of the key applications include: 1. Construction: Round stainless steel bars are commonly used in construction projects for structural support, reinforcement, and fabrication of structures like bridges, buildings, and highways. The high strength and corrosion resistance of stainless steel make it an ideal choice for these applications. 2. Manufacturing: Stainless steel bars are extensively used in manufacturing processes such as machining, forging, and welding. They are used to create various components, fittings, and equipment in industries like automotive, aerospace, and machinery. 3. Food and Beverage Industry: Stainless steel bars are widely used in the food and beverage industry due to their hygienic and non-reactive properties. They are used to create equipment like tanks, pipes, and fittings for storing, processing, and transporting food and beverages. 4. Marine and Offshore Industry: Due to its corrosion resistance, stainless steel bars are extensively used in the marine and offshore industry. They are used in the construction of ships, oil platforms, and offshore structures, where they are exposed to harsh environmental conditions. 5. Medical and Pharmaceutical Industry: Stainless steel bars find applications in the medical and pharmaceutical industry due to their biocompatibility and resistance to corrosion. They are used to manufacture surgical instruments, medical devices, and equipment like implants and prosthetics. 6. Architecture and Design: Stainless steel bars are widely used in architectural and design applications for their aesthetic appeal and durability. They can be found in the form of handrails, balustrades, decorative elements, and furniture. 7. Energy and Power Generation: Stainless steel bars find applications in the energy and power generation industry, particularly in the construction of power plants, turbines, and heat exchangers. Their resistance to high temperatures and corrosion makes them suitable for these applications. Overall, the applications of round stainless steel bars are diverse and varied, thanks to their strength, corrosion resistance, and versatility.

- Q: Are stainless steel bars suitable for the production of turbine rotors?

- Indeed, turbine rotors can be effectively produced using stainless steel bars. Stainless steel boasts remarkable properties, including outstanding strength, corrosion resistance, and heat resistance, rendering it a perfect selection for demanding purposes like turbine rotors. The utilization of stainless steel bars guarantees the essential strength and stability necessary to endure the rigorous rotational velocities and severe operating circumstances endured by turbine rotors. Moreover, stainless steel's ability to resist corrosion ensures the rotor's longevity and reliability throughout its lifespan. Consequently, stainless steel bars emerge as a dependable and appropriate material for the production of turbine rotors.

- Q: How do stainless steel bars perform in cryogenic environments?

- Stainless steel bars exhibit excellent performance in cryogenic environments. Due to their inherent properties, stainless steel bars can withstand extremely low temperatures without losing their structural integrity or mechanical properties. One of the key factors contributing to their success in cryogenic environments is their low thermal conductivity, which helps in minimizing heat transfer and maintaining the desired temperature. Additionally, stainless steel bars possess high corrosion resistance, even in the presence of cryogenic fluids such as liquid nitrogen or helium, which are commonly used in cryogenic applications. This corrosion resistance ensures the longevity and reliability of stainless steel bars in such environments. Furthermore, stainless steel bars offer good strength and toughness, which makes them suitable for use in cryogenic equipment and components that are subjected to high mechanical stresses. Overall, stainless steel bars are highly preferred in cryogenic applications due to their exceptional performance, durability, and resistance to low temperatures and corrosive conditions.

- Q: How are stainless steel bars used in the aerospace industry?

- Stainless steel bars are extensively used in the aerospace industry for various applications such as manufacturing aircraft components, structural supports, and fasteners. These bars possess exceptional strength, corrosion resistance, and heat resistance properties, making them ideal for constructing critical parts that require high durability and reliability. They are commonly used in the fabrication of landing gear, engine mounts, exhaust systems, and structural frameworks. Additionally, stainless steel bars are also utilized in aerospace tooling and machining processes to ensure precision and accuracy during manufacturing.

- Q: What is the difference between centerless ground and peeled stainless steel bars?

- The main difference between centerless ground and peeled stainless steel bars lies in the manufacturing process. Centerless ground bars are produced by grinding the surface of the stainless steel bar to achieve precise dimensions and a smooth finish. This process removes any imperfections and ensures tight tolerances. On the other hand, peeled stainless steel bars are created by removing the outer layer of the stainless steel bar through a peeling process. This results in a smooth, clean surface while retaining the original size of the bar. Overall, centerless ground bars are more suitable for applications that require precise dimensions, while peeled bars are preferred when a smooth surface finish is the main requirement.

- Q: Can stainless steel bars be used in construction projects?

- Yes, stainless steel bars can be used in construction projects. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it a suitable material for various applications in construction, including reinforcement, structural support, and architectural detailing.

- Q: What are the differences between 304 and 316 stainless steel bars?

- 304 and 316 stainless steel bars are both widely used in various industries, but they have distinct differences that make them suitable for specific applications. Firstly, the primary difference between 304 and 316 stainless steel bars lies in their composition. 304 stainless steel is composed of 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. This additional molybdenum in 316 stainless steel provides increased resistance to corrosion and pitting compared to 304 stainless steel. Secondly, due to its higher molybdenum content, 316 stainless steel bars have superior overall corrosion resistance, making them ideal for use in marine environments or applications where exposure to chloride solutions or corrosive chemicals is common. On the other hand, while 304 stainless steel bars offer good corrosion resistance, they may not be as resistant as 316 stainless steel in certain aggressive or high-chloride environments. Thirdly, the difference in composition affects the mechanical properties of the two stainless steel grades. 316 stainless steel bars have higher tensile strength and yield strength compared to 304 stainless steel bars. This makes 316 stainless steel bars more suitable for applications that require greater strength and durability, such as structural components or heavy-duty equipment. Lastly, the cost difference between 304 and 316 stainless steel bars should also be considered. Due to its higher molybdenum content and improved corrosion resistance, 316 stainless steel bars are generally more expensive than 304 stainless steel bars. Therefore, the choice between the two grades will also depend on the budget and specific requirements of the project or application. In summary, the key differences between 304 and 316 stainless steel bars lie in their composition, corrosion resistance, mechanical properties, and cost. Understanding these differences is crucial in selecting the appropriate stainless steel grade for a particular application, ensuring optimal performance and longevity.

Send your message to us

Stainless steel 316 polished round bar H11 tolerance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords