201 Stainless Steel Round Bar Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product name: 201 stainless steel round bar

Name | 201 stainless steel round bar |

Standard | AISI, ASTM, JIS,GB,EN,DIN |

Grade | 201/304/316/304L/316L |

Technology | Hot Drawn and Cold Drawn |

Form | Round/Square/Hexagonal Bar |

Diameter | 0.3 mm – 100mm |

| Length | Customized |

The sizes or thickness of stainless steel Bar can be customized. Our customer service staffs are available 7/24. | |

Chemical Composition (%)< stainless steel bar >

Type | C | Si | Mn | P | S | Ni | Cr | Mo |

201 | ≤0.15 | ≤0.75 | 5.5-7.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 13.5-15.0 | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | ≤0.06 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | |

304 | ≤0.08 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 18.0-20.0 | |

304L | ≤0.03 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 8.0~11.0 | 18.0-20.0 | |

316 | ≤0.08 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.0-3.0 |

316L | ≤0.03 | ≤0.75 | ≤2 | ≤0.045 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.0-3.0 |

Advantages of 201 stainless steel polished round bar

A : Elegance Surface and Diversity Usage

B : Corrosion Resistance and Longer Srevice Life

C :Heat Resistance

D: High Strength

F :High Strength of Oxidation Resistance

G: High Plasticity

H: Easy Surface Treatment

I : Hygiene and High Degree of Finish

J: Excellent Welding Performance

Our experience in developing and pioneering specialized stainless steel fabrications for our customers has made us solidly proficient at prototyping and design.

Because we specialize in multiple industries and reap manufacturing expertise,

we will be able to make your custom parts in the most cost-efficient manner.

Additionally, we have launched our own product line.

We are always open to new challenges and we are constantly working to increase our stainless steel fabricating skills and thereby reduce your costs as well as ours.

Stainless steel manufacturing is an art and a science;

it's a science because we relentlessly seek efficiency

It's an art because we expect and respect your particular needs.

Call us!

We want for your inquiry.

Technological Process of 201 stainless steel polished round bar

Quality Speaks Volumes

Boro has developed and produced premium stainless steel fabrications for over five hundred manufacturing, military, and general industrial companies.

We've run thousands of jobs and thousands of part designs.

We have outstanding deliverability and are ISO BV SGS registered .

So you know you're getting a quality product.

Our experience with reducing costs for our customers through long-run jobs is proven and reliable.

With many long term customers, our stainless steel fabrication services

are low cost and high quality in this present world marketplace.

Boro pursues improvement in every department. Roughly one tenth of company revenue is spent on new technology, renovations, improvements, & strategic market preparation.

Our entire business model (prospect to job close) has been completely value streamed and most of our workflow is strictly managed & controlled.

We maintain records and backups of all pertinent job data.

Company Information

China National Building Materials Group Corporation (CNBM) was established in 1984 with approval of the State Council, and then became a Central Enterprise under direct supervision of State-owned Assets Supervision and Administration Commission of the State Council in 2003. It is in charge of the administrative affairs in China building materials industry. By the end of 2013, CNBM’s total assets exceeded RMB 360 billion, with over 130,000 employees, and 20 companies under direct management with 100% share control or majority control, among which 6 were listed companies, including 2 oversea listed. On July 7th, 2014, CNBM with revenue USD 41028 million, was ranked 267th on the ”World Top 500 Enterprises” by Fortune Magazine.

PACK & DELIVERY

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

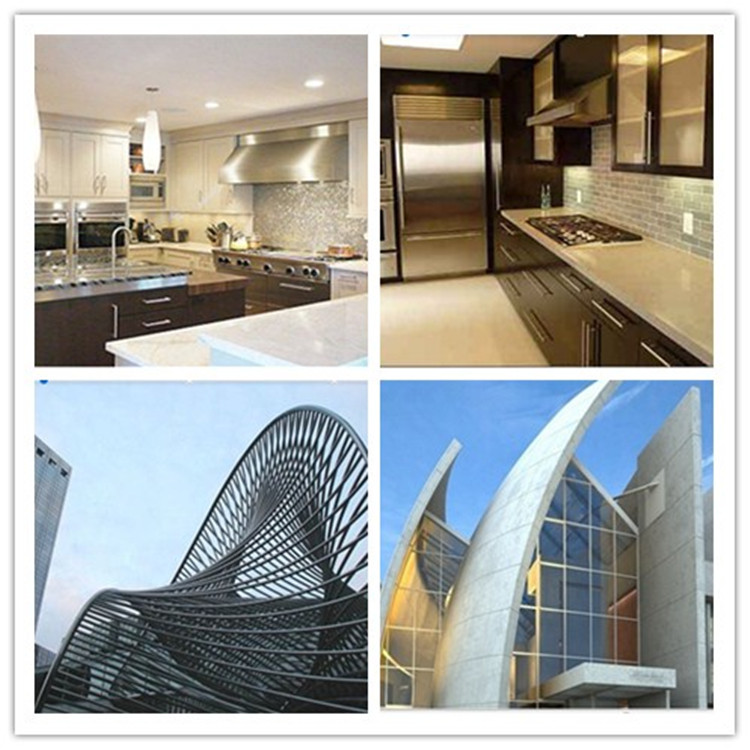

Application

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

- Q: What are the standards for stainless steel bars?

- The standards for stainless steel bars are set by various organizations and bodies, such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO). These standards define the chemical composition, mechanical properties, dimensions, tolerances, and other requirements that stainless steel bars should adhere to in order to ensure their quality, performance, and compatibility in different applications.

- Q: What are the different types of stainless steel bars used in oil refineries?

- There are several types of stainless steel bars that are commonly used in oil refineries due to their high resistance to corrosion and strength properties. These types can be categorized based on their composition and characteristics. 1. Austenitic Stainless Steel Bars: This type of stainless steel is the most commonly used in oil refineries. It contains high levels of nickel and chromium, providing excellent resistance to corrosion, even in acidic environments. Austenitic stainless steel bars are also known for their high strength and toughness, making them suitable for various applications in oil refineries. 2. Duplex Stainless Steel Bars: Duplex stainless steel bars are a combination of austenitic and ferritic stainless steels. They offer a unique combination of high strength and excellent corrosion resistance, particularly against chloride-induced stress corrosion cracking. Duplex stainless steel bars are commonly used in oil refineries where resistance to both corrosion and mechanical stress is required. 3. Martensitic Stainless Steel Bars: Martensitic stainless steel bars are known for their high strength and hardness. They contain higher levels of carbon compared to other stainless steel types, which provides increased strength but reduces their corrosion resistance. Martensitic stainless steel bars are often used in oil refineries for applications that require high strength and wear resistance, such as pumps and valves. 4. Precipitation-Hardening Stainless Steel Bars: Precipitation-hardening stainless steel bars are heat-treated to achieve a combination of high strength and corrosion resistance. They contain alloying elements such as copper, aluminum, or titanium, which form precipitates during heat treatment, strengthening the material. These bars are commonly used in critical components of oil refineries that require both strength and resistance to corrosion. 5. Ferritic Stainless Steel Bars: Ferritic stainless steel bars have a high chromium content, providing good resistance to corrosion and oxidation. They have lower carbon content compared to austenitic stainless steels, which results in lower strength but improved ductility. Ferritic stainless steel bars are often used in oil refineries for applications that require corrosion resistance in mildly acidic or chloride-containing environments. It is important to select the appropriate type of stainless steel bar based on the specific requirements and operating conditions of the oil refinery to ensure optimal performance and longevity of the equipment.

- Q: Are stainless steel bars suitable for food storage containers?

- Yes, stainless steel bars are suitable for food storage containers. Stainless steel is a highly durable and corrosion-resistant material that is commonly used in the food industry. It is non-reactive, meaning it does not leach any harmful chemicals into the stored food, ensuring the safety and quality of the contents. Stainless steel bars are also easy to clean and maintain, making them ideal for food storage containers. Additionally, stainless steel has excellent temperature retention properties, allowing it to keep food hot or cold for extended periods. Overall, stainless steel bars are a reliable and hygienic choice for food storage containers.

- Q: Can stainless steel bars be used in the renewable energy industry?

- Yes, stainless steel bars can be used in the renewable energy industry. Stainless steel is known for its excellent corrosion resistance, strength, and durability, making it a suitable material for various applications in renewable energy projects. One common use of stainless steel bars in the renewable energy industry is in the construction of wind turbine towers. Wind turbines are subjected to harsh environmental conditions, including high winds, saltwater exposure, and temperature fluctuations. Stainless steel bars, due to their corrosion resistance, can withstand these conditions and provide structural integrity to the tower. Stainless steel bars are also used in solar energy systems. They can be used to fabricate support structures for solar panels, ensuring stability and longevity. Additionally, stainless steel bars are used in the manufacturing of solar water heaters, which require materials that can withstand high temperatures and resist corrosion. Moreover, stainless steel bars are used in hydroelectric power plants. They are used in the construction of penstocks, which are large pipes that carry water from a dam to the turbines. Stainless steel's resistance to corrosion and high strength make it an ideal choice for such applications, as it ensures the longevity and reliability of the hydroelectric system. In conclusion, stainless steel bars are widely used in the renewable energy industry due to their corrosion resistance, strength, and durability. Whether it's in wind turbines, solar energy systems, or hydroelectric power plants, stainless steel bars play a crucial role in ensuring the efficiency and longevity of renewable energy projects.

- Q: What is the corrosion resistance of stainless steel bars in alkaline environments?

- In alkaline environments, stainless steel bars excel in resisting corrosion due to their inherent composition. The chromium content in stainless steel creates a protective oxide layer called chromium oxide, acting as a shield against alkaline substances and reducing the risk of corrosion. Moreover, the corrosion resistance of stainless steel in alkaline environments is further enhanced by the inclusion of other alloying elements like nickel and molybdenum. These elements contribute to the formation of a stronger and more durable oxide layer, offering enhanced protection against corrosion. Alkaline environments, which have a high pH level, encompass various applications such as water treatment plants, chemical processing facilities, and concrete structures. Stainless steel bars are commonly utilized in these settings due to their ability to withstand the corrosive nature of alkaline substances. It is crucial to consider that the corrosion resistance of stainless steel may vary depending on the specific grade and surface condition of the bars. Therefore, selecting the appropriate stainless steel grade and ensuring a proper surface finish are essential factors in guaranteeing optimal corrosion resistance in alkaline environments. In summary, stainless steel bars demonstrate outstanding corrosion resistance in alkaline environments. The passive oxide layer formed on the surface of stainless steel, along with the presence of alloying elements, offers effective protection against corrosion in applications where exposure to alkaline substances is a concern.

- Q: What are the different types of stainless steel bar finishes for improved cleanability?

- To improve cleanability, there are various types of finishes available for stainless steel bars. These finishes aim to make the bar surface smoother and more resistant to staining and dirt buildup. One popular finish is the brushed finish, also known as a satin finish. It involves using abrasive materials to create a uniform, brushed pattern on the bar surface. This not only enhances the visual appeal of the bar but also helps conceal any scratches or imperfections that may occur over time. The brushed finish is relatively easy to clean and maintain, making it a preferred choice for applications where cleanliness is crucial. Another type of finish is the mirror finish, achieved by polishing the bar surface to a high shine. This finish is exceptionally smooth and reflective, making it effortless to clean and giving the bar a sleek and modern appearance. However, the mirror finish is more susceptible to scratching and may require more frequent maintenance to retain its pristine look. A third option is the bead blasted finish, achieved by blasting small glass beads at high pressure onto the bar surface. This creates a textured, matte finish that resists fingerprints and is easy to clean. The bead blasted finish is commonly used in applications that desire an industrial or rugged look, as it effectively conceals any surface imperfections. Additionally, there are specialized finishes available for specific applications. For instance, electropolished finishes are utilized in industries like pharmaceuticals and food processing, where an exceptionally smooth and clean surface is necessary to prevent contamination. These finishes are achieved by immersing the stainless steel bar in an electrolyte solution and applying an electric current, resulting in the removal of surface imperfections and the creation of a highly polished finish. Ultimately, the choice of stainless steel bar finish depends on the specific requirements of the application, as well as factors like aesthetics and ease of maintenance. By selecting the appropriate finish, it is possible to enhance the cleanability of stainless steel bars and ensure they remain in optimal condition for extended periods of time.

- Q: What's the difference between stainless steel wire and stainless steel bar?

- The biggest difference between stainless steel wire and stainless steel bar is that one is coil and the other is straight bar.

- Q: Can stainless steel bars be used in chemical storage applications?

- Indeed, chemical storage applications can utilize stainless steel bars. Renowned for their exceptional corrosion resistance and durability, stainless steel bars are widely favored for the storage of diverse chemicals. They exhibit resistance to a broad spectrum of chemicals, encompassing acids, alkalis, and solvents, thereby rendering them suitable for the storage of corrosive compounds. Furthermore, stainless steel bars are easily cleaned and maintained, a pivotal aspect in chemical storage applications to prevent contamination. Moreover, stainless steel possesses commendable strength and temperature resistance, guaranteeing the structural integrity of the storage system. In summary, stainless steel bars represent a dependable and secure choice for chemical storage applications.

- Q: Can stainless steel bars be used in the chemical industry?

- Stainless steel bars are indeed applicable in the chemical industry. This particular material is widely favored in this field because of its ability to resist corrosion and its impressive strength. Thanks to these features, stainless steel is able to withstand the harshest chemicals, acids, and alkalis, which allows for its use in tasks involving corrosive substances. Moreover, stainless steel bars are employed in the construction of chemical processing equipment, including tanks, pipes, valves, and fittings. They are also utilized for the storage and transportation of chemicals, as they provide a sturdy and dependable solution. Furthermore, stainless steel bars can endure high temperatures, making them a fitting choice for applications involving heat or thermal cycling. All in all, stainless steel bars are a versatile and practical option for the chemical industry, owing to their remarkable resistance to corrosion and durability.

- Q: Are stainless steel bars suitable for the medical industry?

- Yes, stainless steel bars are suitable for the medical industry. Stainless steel is known for its durability, corrosion resistance, and ability to withstand high temperatures, making it ideal for medical equipment, surgical instruments, and implants. It is also easy to clean and sterilize, making it a hygienic choice for healthcare environments.

Send your message to us

201 Stainless Steel Round Bar Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords