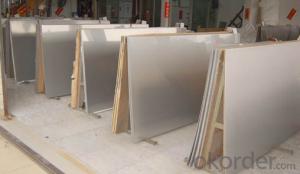

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: What is lined with stainless steel?

- Stainless steel lining is a method of trenchless repair of underground pipes.

- Q: What is the maximum length of stainless steel pipes available?

- The maximum length of stainless steel pipes available varies depending on the manufacturer and specific product. However, commonly, stainless steel pipes can be found in lengths ranging from 20 feet to 40 feet.

- Q: What is the difference between inside diameter and outside diameter in stainless steel pipes?

- The inside diameter refers to the measurement of the inner space or bore of a stainless steel pipe, while the outside diameter refers to the measurement of the outer circumference or width of the pipe. Essentially, the inside diameter determines the flow capacity of the pipe, while the outside diameter determines the overall size and strength of the pipe.

- Q: Can stainless steel pipes be used for wastewater treatment plants?

- Certainly! Wastewater treatment plants can utilize stainless steel pipes. Stainless steel, being remarkably durable and resistant to corrosion, proves to be an excellent selection for use in challenging settings like wastewater treatment plants. Its corrosion resistance aids in averting leaks and reducing the need for maintenance, thereby guaranteeing extended pipe longevity. Moreover, stainless steel pipes are sanitary and effortless to clean, a critical aspect in wastewater treatment plants where cleanliness and sanitation are paramount. All in all, stainless steel pipes offer a dependable and effective means of transporting wastewater within treatment plants.

- Q: What is the maximum temperature stainless steel pipes can handle?

- The specific grade of stainless steel being utilized determines the maximum temperature that can be endured by stainless steel pipes. Generally, stainless steel possesses a reputation for its exceptional resistance to high temperatures and can maintain its structural integrity within a temperature range of -150°C (-238°F) to 1100°C (2012°F). Yet, the precise maximum temperature differs depending on variables including the grade of stainless steel, the intended use, and the length of time exposed to elevated temperatures. To ascertain the maximum temperature limit for a specific stainless steel pipe, it is crucial to refer to the manufacturer's specifications and guidelines.

- Q: What is the maximum temperature that stainless steel pipes can withstand?

- The grade of stainless steel used determines the maximum temperature that stainless steel pipes can tolerate. Typically, stainless steel pipes have the capability to withstand elevated temperatures between 1200 and 1600 degrees Fahrenheit (650 to 870 degrees Celsius). Nevertheless, it is crucial to acknowledge that extended exposure to these extreme temperatures can weaken the stainless steel, potentially leading to deformation or failure. To determine the maximum temperature limits for a specific grade of stainless steel pipe in a particular application, it is always advisable to refer to the manufacturer's guidelines or consult with a materials engineer.

- Q: Where is the difference between seamless steel pipe and welded pipe?

- The steel tube is a hollow steel strip, used as pipe conveying fluid, such as oil, gas, water, gas, steam, in addition, the bending and torsional strength of the same, the weight is light, so it is widely used in the manufacture of machinery parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: What is the difference between 446 and 316 stainless steel pipes?

- The chemical composition and intended use distinguish 446 stainless steel pipes from 316 stainless steel pipes. 446 stainless steel, a heat-resistant alloy, is ferritic and contains chromium, molybdenum, and small amounts of silicon and carbon. This composition grants 446 stainless steel exceptional oxidation resistance at high temperatures, making it suitable for the automotive, power generation, and thermal processing industries. It can withstand temperatures up to 1500°C (2730°F) and displays good corrosion resistance in specific environments. Conversely, 316 stainless steel is an austenitic, corrosion-resistant alloy containing chromium, nickel, and molybdenum. Due to its superior corrosion resistance and ability to endure harsh conditions, it finds wide application in industries such as food processing, pharmaceuticals, marine applications, and chemical processing. Additionally, 316 stainless steel offers good resistance to pitting and crevice corrosion, making it appropriate for chloride-containing environments. In terms of mechanical properties, 446 stainless steel generally exhibits lower tensile strength and hardness compared to 316 stainless steel. However, it compensates for this by providing better high-temperature oxidation resistance. Conversely, 316 stainless steel possesses higher tensile strength and hardness, resulting in superior overall mechanical properties. In conclusion, while both 446 and 316 stainless steel pipes offer corrosion resistance, their chemical composition and specific application areas are the key distinguishing factors. 446 stainless steel is primarily suitable for high-temperature environments, whereas 316 stainless steel is more versatile and extensively employed in various industries due to its superior corrosion resistance properties.

- Q: Do stainless steel pipes require insulation?

- Stainless steel pipes generally do not require insulation, as they have a high resistance to corrosion and can withstand high temperatures. However, there are certain situations where insulation may be necessary. For instance, when transporting fluids at extremely low temperatures, insulation helps to prevent heat transfer and maintain the temperature of the fluid. Additionally, in environments where condensation may occur, insulation can prevent moisture from forming on the pipes and causing potential damage. Overall, the need for insulation in stainless steel pipes depends on the specific application and the conditions in which they are used.

- Q: Are stainless steel pipes resistant to acidic solutions?

- Generally, stainless steel pipes exhibit resistance to acidic solutions due to the high chromium content. This chromium forms a protective layer that shields the metal from corrosion, preventing any harm caused by the acid. Nevertheless, the level of resistance can differ among various grades of stainless steel. Certain grades offer greater acid resistance compared to others. To determine the most appropriate grade for a specific application involving acidic solutions, consulting the manufacturer or a corrosion specialist is essential.

Send your message to us

Stainless Steel 304 sheet with competitive pricing and top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords