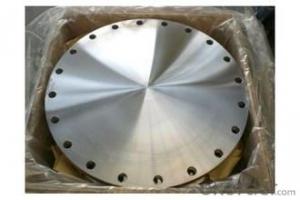

STAIN STEEL PIPE FORGED FLANGES A105 ANSI B16.5 best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package Of Stainless Steel Butt-Welded Fitting:

PACKED IN PLYWOOD CASES OR PALLETS

Painting Of Stainless Steel Butt-Welded Fitting:

ANTI-RUST OIL

Marking Of Stainless Steel Butt-Welded Fitting:

REFER TO MARKING DOCUMENT or AS PER CUSTOMER REQUEST

Shipping Marks Of Stainless Steel Butt-Welded Fitting:

EACH WOODEN BOX TWO PLASTIC SHIPPING MARKS

Specification Of Stainless Steel Butt-Welded Fitting:

Stainless Steel 90Deg LR Elbow, Tee, Reducer and Cap

Size : 1/2"-48"

Wall Thickness.: SCH10-SCH160, SGP , XS, XXS, DIN ,STD

| Name | Stainless Steel Butt-Welded Fitting |

| Size | 1/2" - 48" |

| ANGLE | 45D 90 D 180D |

| Wall thickness | Sch5-Sch160 XXS,STD,XS, SGP |

| Standard | ASME B16.9, GOST 17375-2001, DIN2605 and JIS B2311, EN10253-1 etc. |

| We can also produce according to drawing and standards provided by customers. | |

| Material | 304, 304L, 316, 316L, 304/304L, 316/316L, EN1.4301, EN1.4404 etc. |

| Packaging | Wooden Cases, wooden pallet , or carton box , or nylog bag and then in wooden cases |

| Surface Treatment | Anti-rust Oil |

| Delivery Time | 20-30 days, after received advance payment. |

| Quality | 100% Heat Treatment, No Welding repair |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2000 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| 5. we have export right , offering FOB , CNF CIF price |

STANDARD & MATERIAL GRADE

STANDARD Of Carbon Steel Butt-Welded Fitting

| Standard | Wall Thickness | Type | |

| American Standard | ASME B16.9 | S5S ~ XXS | 45D, 90D, 180D ELBOW, TEE, REDUCER, CAP, STUB END |

| ASME B16.11 | |||

| ASME B16.28 | 90D SR ELBOW | ||

| Japanese Standard | JIS B2311 | SGP ~ LG |

MATERIAL Of Stainless Steel Flange

| Stainless Steel | ||

| Material Standard | Material Grade | |

| ASTM | ASTM A182 | F304 / F304 L |

| ASTM A182 | F316/ F316L | |

| ASTM A182 | F310, F321 | |

| ASTM A182 | F321 | |

| DIN EN | DIN EN 10222-5 | EN 1.4301 |

| DIN EN 10222-5 | EN 1.4404 | |

| JIS | JIS G3214 | SUS F304 |

| JIS G3214 | SUS F304L | |

| JIS G3214 | SUS F316 | |

| JIS G3214 | SUS F316L | |

- Q: How can the immersed pipe pile put steel cage into the steel pipe? Which expert to answer?

- The pile reinforcement cage construction characteristics: in general application of the reinforcement cage can be used when not required manual assembling reinforcement cage, such as deep or large pile diameter should be used for solid and solid mechanism of reinforcement cage better (by reinforcing cage seam welder production) to meet Zhuang Jishi high technology requirements, enhance the stability of pile foundation.

- Q: How are steel pipes used in the manufacturing sector?

- Steel pipes are widely used in the manufacturing sector for various purposes such as transporting fluids, gases, and solid materials, as well as providing structural support in buildings and machinery. They are commonly used in industries like oil and gas, construction, automotive, and manufacturing plants for their durability, strength, and resistance to corrosion. Steel pipes enable efficient and reliable transportation of materials, facilitating the manufacturing process and ensuring the smooth operation of industrial systems.

- Q: How to descaling galvanized steel pipe?

- If the substrate is rusty, rust removal can be removed by acid leaching. If the coating is rusted, it can also be dipped in acid, but this will also remove the coating and make the base material more susceptible to rust, preferably by re plating and passivation

- Q: What are the environmental impacts of steel pipe production?

- The environmental impacts of steel pipe production include the extraction of raw materials (iron ore, coal, and limestone) which leads to habitat destruction and soil erosion. The manufacturing process requires significant energy, contributing to greenhouse gas emissions and air pollution. Additionally, the production generates waste materials, such as slag and by-products, that can contaminate water sources if not properly managed. Finally, the transportation of steel pipes adds to carbon emissions and can disrupt ecosystems if not done sustainably.

- Q: What are the different types of steel pipe flanges?

- There are several different types of steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, lap joint flanges, and orifice flanges. Each type has its own unique design and purpose, catering to specific applications and requirements in various industries.

- Q: What is the outer diameter of the steel tube?

- The outer diameter refers to the maximum diameter including the thickness of the steel tube, the inner diameter is the length of the hollow part inside, and the outer diameter minus the inside diameter is the thickness of the steel pipe

- Q: What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- The difference between hot rolled seamless steel tube and cold rolled seamless steel tube:1) cold-rolled seamless tubes tend to be of small diameter, and hot-rolled seamless tubes are often of large diameter.2) the accuracy of cold-rolled seamless steel tube is higher than that of hot-rolled seamless steel tube, and the price is higher than that of hot-rolled seamless steel tube.

- Q: What do you mean by "SC" in welded pipe SC200? What's the diameter of 200?

- 200 refers to the diameter of the pipe. Personally, you should be an electrical professional, but the electrical specialty rarely uses the 200 pipe diameter unless it is used when the buried cable passes the road;

- Q: What is the maximum temperature that steel pipes can handle?

- The maximum temperature that steel pipes can handle varies depending on the specific grade and type of steel used. However, in general, steel pipes can withstand high temperatures ranging from 750 to 1200 degrees Celsius (1382 to 2192 degrees Fahrenheit).

- Q: How are steel pipes connected in pipeline construction?

- Steel pipes are connected in pipeline construction through various methods such as welding, threading, and flanging. Welding involves joining the pipes using heat and fusion, creating a strong and durable connection. Threading involves screwing two pipes together using threads on the ends of the pipes. Flanging involves connecting the pipes by bolting together flanges on the ends of each pipe. These connection methods ensure a secure and leak-proof pipeline system.

Send your message to us

STAIN STEEL PIPE FORGED FLANGES A105 ANSI B16.5 best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords