Adjustable Solar Mounting System - Solar Hook PV Solar Roof Hook Roof Tile Hook

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

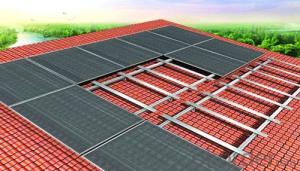

Solar Hook PV solar Roof Hook roof tile hook

Specifications

Solar Power SystemSolar Roof Mount High Rise Flashing Hook

ISO 9001,AS/NZS 1170&TUV certified

Easy installation,warranty 10

Material | Aluminum AL6005-T5 |

Standard | AS/NZS 1170, TUV |

Install Site | roof |

Install Angle | 0-60 degree |

Max Building Height | 20 m |

Wind load | 130mph(60m/s) |

Snow Load | 30psf(1.4kN/m2) |

Anticorrosive | Anodized or hot galvanized |

Color | Natural or Customized |

Warranty | 10 years |

Duration | More than 20 years |

Do not use paint or petroleujm based products on rubber collars

including high rise bar , high rise flashing and L feet kit

Flexibility: roof mount, pole mount, ground mount, ballasted mount, etc both for on grid and off-grid systems, for framed and frameless panels

Easy Installation: All kits are highly assembled in factory. The tilt in module can be located in any location of rails.

MOQ: Sample orders are allowed

Delivery Time: 3-15 days when orders are confirmed

You are welcome to send us an inquiry for more information. Our products can meet requirement of any install solutions. Customized designs are accepted.

- Q: Can a solar mounting system be installed on a rooftop with a barrel roof?

- Yes, a solar mounting system can be installed on a rooftop with a barrel roof. However, it may require custom mounting solutions to accommodate the curved shape of the roof.

- Q: What materials are used in solar mounting systems?

- The materials used in solar mounting systems can vary, but common ones include aluminum, steel, and stainless steel. These materials are chosen for their durability, strength, and resistance to corrosion, ensuring the stability and longevity of the solar panel installation.

- Q: Can a solar mounting system be used in areas with solar incentives for warehouses?

- Yes, a solar mounting system can be used in areas with solar incentives for warehouses. These incentives encourage the adoption of renewable energy sources, such as solar power, and provide financial benefits to businesses that install solar systems. Therefore, installing a solar mounting system in warehouses with solar incentives can help businesses take advantage of these incentives and reduce their electricity costs while promoting sustainability.

- Q: Can a solar mounting system be installed on a data center or IT facility?

- Yes, a solar mounting system can be installed on a data center or IT facility. Solar panels can be mounted on the roof or ground of the facility to harness solar energy and offset the electricity consumption. This can help reduce the facility's carbon footprint and lower energy costs. However, it is important to consider factors such as structural integrity, orientation, and shading to ensure optimal performance of the solar system.

- Q: Can solar mounting systems be installed on buildings with limited roof load capacity?

- Yes, solar mounting systems can be installed on buildings with limited roof load capacity. There are various lightweight and low-profile options available in the market that are specifically designed for such buildings. These mounting systems distribute the weight of the solar panels evenly, minimizing the stress on the roof structure. Prior to installation, it is recommended to consult with a professional engineer or solar installer to assess the roof's load capacity and determine the best mounting system suitable for the specific building.

- Q: Can a solar mounting system be installed on a rooftop with a flat metal roof?

- Yes, a solar mounting system can be installed on a rooftop with a flat metal roof. The specific type of mounting system will depend on the characteristics of the roof, such as its load-bearing capacity and the angle of inclination desired for optimal solar energy production. However, with the proper design and installation techniques, solar panels can be securely mounted on a flat metal roof, allowing for the generation of solar power.

- Q: Can a solar mounting system be used with solar concentrators?

- Yes, a solar mounting system can be used with solar concentrators. Solar concentrators are designed to focus sunlight onto a smaller area, increasing the intensity of the light. These concentrators can be mounted on a solar mounting system, allowing for optimal positioning and tracking of the concentrators to maximize energy output.

- Q: How do you secure a solar mounting system to a roof?

- A solar mounting system can be secured to a roof using various methods, typically dependent on the type of roof and the specific mounting system being used. Common approaches include using roof anchors, flashing, and fasteners to secure the mounting rails or brackets directly to the roof structure. Additionally, ballast or weight can be used to secure the mounting system on flat roofs, while standing seam clamps are commonly employed for metal roofs. It is crucial to follow manufacturer guidelines and consult with professionals to ensure proper installation and secure attachment that does not compromise the integrity of the roof.

- Q: Can a solar mounting system be used in areas with solar incentives for breweries?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for breweries. These mounting systems provide the necessary infrastructure for installing solar panels on rooftops or open grounds, allowing breweries to take advantage of the incentives offered for adopting solar energy. By utilizing a solar mounting system, breweries can not only generate clean and renewable energy but also potentially reduce their energy costs and contribute to a more sustainable future.

- Q: Can a solar mounting system be used for both grid-tied and off-grid systems?

- Yes, a solar mounting system can be used for both grid-tied and off-grid systems. The mounting system itself is independent of the system's connection to the grid. It is designed to securely hold the solar panels in place, regardless of whether the system is connected to the grid or not.

Send your message to us

Adjustable Solar Mounting System - Solar Hook PV Solar Roof Hook Roof Tile Hook

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords