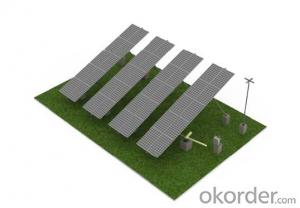

S Rack HCPV Dual-Axis Tracking System Solar Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction:

HCPV dual-axis tracking system is high-tech petented product.

The tracker bracket adopt hot-dipped galvanizde high-quality structual steel Q235B,system stability is very high and maintenance cost is very low,working time more than 25years.

adopt pillar type structure,the bearing is free of oil and windproof.

the two axis both using slewing drive.

frame stucture with 5 supporting points.

power generating can increased more then 40%.

Features:

1. The system, which uses an isosceles triangle bracket as bracket structure and maintenance-free, wind and sand-proof high polymer material bearing moving parts and unique linkage structure, features reliable system stability, low cost and low failure rates.

2. Compared with traditional fixed-bracket its annual energy output can be increased up to approximately 20 percent - 30 percent.

3. With exactly the same or even lower cost as fixed-bracket the system is the optimal choice for the establishment of large and medium-sized high-efficiency solar power stations.

Specification:

• Installed capacity | • 2KW—20KW |

• control method | • light control • time control • light/time control |

• Tracking accuracy | • ≤0.1° |

• Track elevation | • 0—75° |

• Tracking azimuth | • 245° |

• The safe operation of wind speed • | • 75km/h |

• Maximum wind resistance | • 150km/h |

• Drive type | • Rotary gear drive |

• Driving motor power | • DC24V/30W—100W |

• Structural materials | • Q235 Hot dip galvanized steel |

• Protection grade • | • I P 6 5 |

• Service / warranty • | • 25Y/2Y |

• Working environment temperature | • -35℃—65℃ |

• Net area | • 10㎡—120㎡ |

•The weight of the system | • 500kg—3000kg |

FAQ:

1. How long will my inquiry get response?

Your inquiry related to our products or prices will be replied within 24 hours.

2. Can I get professional service and suggestion?

Well-trained and experienced staffs to answer all your questions in fluent English.

3. Do you accept OEM or customized design?

OEM & ODM, any your customized lightings we can help you to design and put into product.

4. What if I need specific design?

Distributorship are offered for your unique design and some our current models.

- Q: How does the orientation of a solar mounting system affect its performance?

- The orientation of a solar mounting system significantly affects its performance. The system should be ideally positioned to maximize sunlight exposure throughout the day. The angle and direction of the system can determine the amount of solar energy captured, thus impacting the overall efficiency and output of the solar panels. Proper orientation ensures that the panels receive maximum sunlight, leading to higher energy production and improved overall performance of the solar mounting system.

- Q: Can a solar mounting system be installed on a ground platform or foundation?

- Yes, a solar mounting system can be installed on a ground platform or foundation. Ground-mounted solar systems are commonly used in situations where roof space is limited or unsuitable for installation. The mounting system is securely anchored to the ground, providing a stable foundation for the solar panels.

- Q: Can a solar mounting system be used on thatched roofs?

- No, a solar mounting system cannot be used on thatched roofs due to the flammable nature of thatched materials.

- Q: Can a solar mounting system be installed on a residential development or community?

- Yes, a solar mounting system can be installed on a residential development or community. In fact, it is becoming increasingly common for homeowners and communities to adopt solar energy as a sustainable and cost-effective solution for their energy needs. By installing solar panels on rooftops or in communal spaces, residential developments and communities can generate clean and renewable electricity, reduce their carbon footprint, and potentially save on energy costs in the long run.

- Q: Can a solar mounting system be used in areas with seismic activity?

- Yes, a solar mounting system can be used in areas with seismic activity. However, it is important to ensure that the mounting system is designed and engineered to withstand seismic forces. Special considerations such as appropriate anchoring techniques, structural reinforcements, and flexible connections may be required to ensure the system's stability and prevent damage during seismic events.

- Q: Can a solar mounting system be installed on a pergola or shade structure?

- Yes, a solar mounting system can be installed on a pergola or shade structure. These structures provide an ideal platform for mounting solar panels as they offer sufficient space and support. Additionally, the pergola or shade structure can provide shade to the panels, which can improve their efficiency by preventing overheating.

- Q: Can a solar mounting system be used in areas with solar incentives for wineries?

- Yes, a solar mounting system can be used in areas with solar incentives for wineries. These mounting systems allow wineries to install solar panels on their rooftops or open land, taking advantage of the available incentives and harnessing solar energy to meet their power needs. The solar incentives help reduce the upfront costs of installing the system and provide financial benefits, making it an attractive option for wineries looking to go solar.

- Q: Can a solar mounting system be installed on a military or defense facility?

- Yes, a solar mounting system can be installed on a military or defense facility. In fact, many military and defense facilities worldwide have already embraced solar energy as a part of their sustainability initiatives. Installing solar panels on these facilities not only helps reduce their carbon footprint and energy costs but also ensures a more reliable and independent source of power in case of emergencies or disruptions to the grid.

- Q: Can a solar mounting system be installed on a transportation or logistics hub?

- Yes, a solar mounting system can be installed on a transportation or logistics hub. These hubs often have large rooftops or open spaces that can be utilized for solar panel installation. By harnessing solar energy, these hubs can reduce their reliance on traditional power sources and lower their carbon footprint. Additionally, the excess energy generated can be stored or sold back to the grid, providing economic benefits.

- Q: Are there any specific requirements for installing a solar mounting system on a tile roof?

- Yes, there are specific requirements for installing a solar mounting system on a tile roof. These requirements typically include ensuring that the roof tiles are in good condition and can support the weight of the solar panels, as well as proper waterproofing and flashing techniques to prevent any leaks. It is also important to use appropriate mounting brackets and hardware designed specifically for tile roofs to ensure a secure and durable installation.

Send your message to us

S Rack HCPV Dual-Axis Tracking System Solar Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords