Best Ballasted Solar Mounting System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

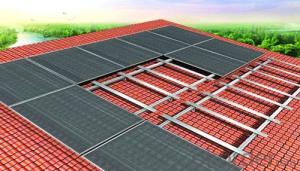

Ballasted Solar Mounting System

Ballasted mounting System is a highly engineered solution that secures the array without damaging the flat roof. It is compatible with the usual framed photovoltaic modules and typically does not require roof penetrations. Made from lightweight and strong aluminum construction, the solar ballasted solution will arrive pre-assembly and pre-cut to prevent corrosion and save your labor cost and installation time.

Features:

Install site :Flat Roof

Tilt Angle :5deg, 10deg, 15deg, 20deg,

Module Orientation: Landscape

Building Height:<20 m

Max Wind Speed:<60m/s

Snow Load:<1.4KN/m2

Distributed weight: 10~25 kg/m2

Standard :AS/NZS 1170 and other international Standard

Material :High Class Aluminum alloy Al6005-T5& Stainless steel fasten

Color: Natural

Warranty:Ten years warranty and twenty years service life.

Benefits:

Easy to install. The pre-assembly support bracket can be connected easily with the rail to mount the framed solar panels. No prior training or staging is required but a detailed installation instruction. Ease of installation means lower project cost.

Offer unmatched durability: with all structural components comprised of high class stainless steel and anodized aluminum alloy, it is designed for twenty years service life and backed by ten years warranty.

Stand up to extreme weather. The grace solar ballasted mounting system is designed to stand up to the extreme weather complied with the AS/NZ 1170 and other international structure load standard by the skilled engineer. The main support components also have been test to guaranty its structure and load-carrying capacity.

Provide broad installation flexibility. These systems accommodate most commercially available framed solar panels and diverse roof types, and they can scale easily from small to large, multi-megawatt installations.

- Q:What is the support frame at the bottom of the car?

- It is a spring spring pin to the front end of the leaf spring and the front of the steel plate spring front bracket connected together, the front end of the ear hole to reduce the wear and tear with a bushing.

- Q:Are there any specific requirements for installing a solar mounting system on a sloped concrete roof?

- Yes, there are specific requirements for installing a solar mounting system on a sloped concrete roof. Some of the key requirements include ensuring that the roof is structurally sound and capable of supporting the added weight of the solar panels and mounting system. Additionally, the angle of the slope should be considered to optimize the solar panel's exposure to sunlight. Proper waterproofing and sealing measures must also be taken to prevent any leaks or damage to the roof. It is recommended to consult with a professional installer or engineer to ensure that all necessary requirements are met for a safe and effective installation.

- Q:Can a solar mounting system be used on thatched roofs?

- Yes, a solar mounting system can be used on thatched roofs with the proper installation techniques and precautions. It is important to ensure that the system is securely anchored to the underlying structure and that the thatched roof is not compromised in the process. Working with experienced professionals who are familiar with both solar installations and thatched roofs is recommended for a safe and effective integration.

- Q:Can a solar mounting system be installed on a rooftop with a BUR roof?

- Yes, a solar mounting system can be installed on a rooftop with a Built-Up Roof (BUR). BUR roofs are commonly used in commercial buildings and provide a suitable surface for solar panel installation. However, it is important to consult with a professional to ensure proper installation techniques and potential modifications required for the BUR roof system.

- Q:Are there specific requirements for the roof to install a solar mounting system?

- Yes, there are specific requirements for installing a solar mounting system on a roof. The most important requirement is that the roof should be structurally sound and capable of supporting the weight of the solar panels. Additionally, the roof should have enough unshaded space to accommodate the panels and receive adequate sunlight. The orientation and angle of the roof may also affect the efficiency of the solar system. It is recommended to consult with a professional solar installer to assess the specific requirements for your roof.

- Q:Are there any specific requirements for installing solar mounting systems in high-altitude areas?

- Yes, there are specific requirements for installing solar mounting systems in high-altitude areas. The main consideration is the impact of low atmospheric pressure and extreme weather conditions often experienced at higher altitudes. These factors can affect the structural integrity and performance of the mounting systems. Therefore, solar mounting systems designed for high-altitude areas should be able to withstand lower air pressure, strong winds, heavy snow loads, and temperature fluctuations. Additionally, proper grounding and lightning protection measures should be implemented to ensure the safety of the system and nearby structures.

- Q:Can a solar mounting system be installed on a theater or performing arts venue?

- Yes, a solar mounting system can be installed on a theater or performing arts venue. The mounting system can be designed to accommodate the specific requirements and structural considerations of the venue, such as the roof type and load-bearing capacity. Installing solar panels on a theater or performing arts venue can be a sustainable and cost-effective way to generate renewable energy and reduce the venue's carbon footprint.

- Q:Are there any specific requirements for telecommunications or remote monitoring system integration when using a solar mounting system?

- Yes, there may be specific requirements for telecommunications or remote monitoring system integration when using a solar mounting system. These requirements can vary depending on the specific project and its goals. However, some common requirements may include the need for reliable internet connectivity, data communication protocols, and compatibility with the solar mounting system's hardware and software. It is important to consult with experts or manufacturers to ensure proper integration of telecommunications or remote monitoring systems with the solar mounting system.

- Q:How does a solar mounting system affect the roof's acoustics?

- A solar mounting system generally has minimal impact on the roof's acoustics. While the installation of such a system may involve drilling or fastening components to the roof, these activities typically do not significantly alter the acoustics of the roof. However, it is important to ensure that the installation is done properly to avoid any potential vibrations or noise caused by loose or improperly secured components.

- Q:Can a solar mounting system be installed on a casino or gaming facility?

- Yes, a solar mounting system can be installed on a casino or gaming facility. In fact, many casinos and gaming facilities are increasingly adopting solar energy systems to reduce their carbon footprint and save on electricity costs. The large roof spaces available on these buildings make them ideal for installing solar panels, which can generate clean and renewable energy to power the facility. Additionally, the installation of a solar mounting system can also serve as a visible symbol of the facility's commitment to sustainability and environmental responsibility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Ballasted Solar Mounting System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords