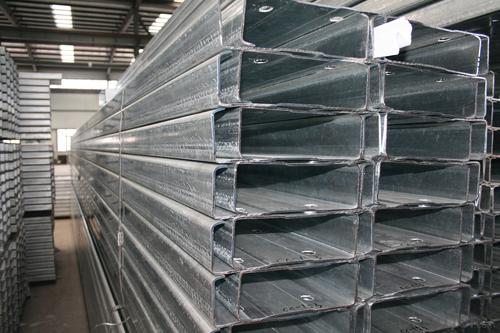

Schuco Solar Mounting Systems for Photovoltaic After Leaching Zinc C Steel Stents

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Photovoltaic after Leaching Zinc C Steel Stents at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Photovoltaic after Leaching Zinc C Steel Stents are ideal for structural applications and are widely used in teel structure building of purlin, wall beam, also can combine into a lightweight roof, bracket and other construction. In addition, can also be used for mechanical column, beam of light manufacturing and arm, etc.

Product Advantages:

OKorder's Photovoltaic after Leaching Zinc C Steel Stents are very accord with roofing purline, metope purlin, the mechanical characteristics, make the mechanical performance of steel use light points. A variety of accessories can be connected into different combinations, appearance beautiful, use steel purlin, can reduce the roof weight, decrease engineering steel, therefore is called economic efficient steel, is instead of Angle steel, channel steel, steel pipes and other new building materials of the traditional steel purlin.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

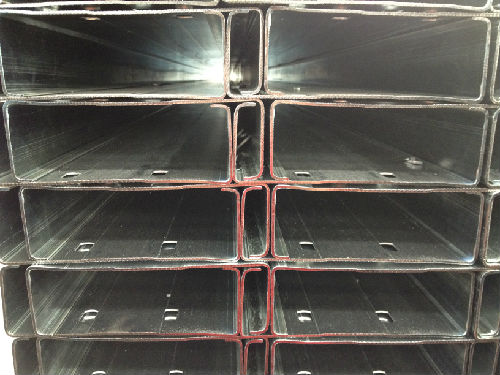

Product Specifications:

Manufacture: cold bending

Grade: Q195 Q215 Q235 Q235B Q345B

Certificates: ISO, SGS, BV, CIQ

Rolling width of 60-400 mm,

Thickness 1.5-4.5 mm

Length: 6m – 12m, as per customer request

Standard: ISO9001:2000

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 30-45days.

Images:

- Q: How does a solar mounting system affect the building's structural integrity?

- A solar mounting system typically has minimal impact on a building's structural integrity. The system is designed to distribute the weight of solar panels evenly across the roof, minimizing stress on the structure. Additionally, modern mounting systems are engineered to be lightweight and non-penetrating, reducing the risk of any significant damage. However, it is important to ensure that the mounting system is installed properly and in accordance with relevant building codes to maintain the structural integrity of the building.

- Q: Can a solar mounting system be installed on an energy-efficient building or Passive House?

- Yes, a solar mounting system can be installed on an energy-efficient building or Passive House. In fact, integrating solar panels into such structures can further enhance their sustainability and reduce their reliance on external energy sources. The design and installation of the mounting system would need to be carefully planned to ensure compatibility and maintain the building's energy efficiency standards.

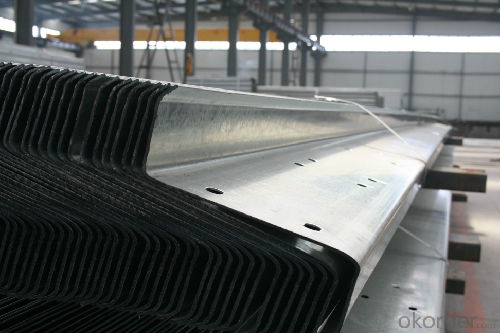

- Q: What are the benefits of finished stents?

- U finished stent relative to the traditional angle steel channel welding stent in addition to the advantages of beautiful, fast installation, but also in its surface without the need for rust paint, galvanized in advance to do so to extend its useful life, maintenance-free.

- Q: What are the benefits of using a solar mounting system?

- The benefits of using a solar mounting system include increased efficiency in harnessing solar energy, improved safety and durability of solar panels, flexibility in installation options, and potential cost savings in the long run due to reduced maintenance and increased energy production.

- Q: Can a solar mounting system be used in areas with limited access to solar industry events?

- Yes, a solar mounting system can be used in areas with limited access to solar industry events. The availability of solar industry events may provide valuable networking and educational opportunities, but it is not a prerequisite for using a solar mounting system. Solar mounting systems can be designed, installed, and maintained by qualified professionals who are knowledgeable about the technology and best practices, regardless of the proximity to industry events. Additionally, there are numerous online resources, training programs, and industry publications that can help individuals in areas with limited access to stay informed and up to date with the latest advancements in the solar industry.

- Q: Can a solar mounting system be installed on a rooftop with a gravel roof?

- Yes, a solar mounting system can be installed on a rooftop with a gravel roof. However, additional precautions and considerations may be necessary, such as ensuring proper waterproofing and stability of the mounting system. Consultation with a professional installer is recommended to ensure the feasibility and safety of the installation.

- Q: Are there any specific requirements for installing solar mounting systems in snowy or icy regions?

- Yes, there are specific requirements for installing solar mounting systems in snowy or icy regions. These requirements typically include using specialized snow or ice guards to prevent snow accumulation on the solar panels, ensuring a steeper tilt angle to allow snow to slide off more easily, and using strong and durable mounting systems that can withstand heavy snow loads. Additionally, regular maintenance and clearing of snow or ice from the panels may be necessary to optimize energy production.

- Q: How to build an effective teaching stent

- analysis of teaching problems and needs, design solutions to teaching problems and strategies to implement the design, evaluation, and constantly improve the design of a systematic process.

- Q: Can a solar mounting system be used on sloped roofs?

- Yes, a solar mounting system can be used on sloped roofs. In fact, many solar installations are done on sloped roofs as it allows for better sunlight exposure and maximizes the energy production of the solar panels. However, the mounting system needs to be specifically designed and installed to accommodate the slope of the roof and ensure the panels are securely and correctly positioned.

- Q: Which type of solar mounting system is best for residential installations?

- The best type of solar mounting system for residential installations is typically the rooftop mounting system. It is the most common and cost-effective option as it utilizes the existing structure of the roof to support the solar panels. This system is easy to install, requires less space, and provides optimal sun exposure for maximum energy generation.

Send your message to us

Schuco Solar Mounting Systems for Photovoltaic After Leaching Zinc C Steel Stents

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords