Sandwichpanel Prefabricated House | Camp House Sandwichpanele

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Eps Sandwich Panel Water Proof Sandwich Panel

Light weight

High intensity Sound proof Easy installation

Eps Sandwich Panel Water Proof Sandwich Panel

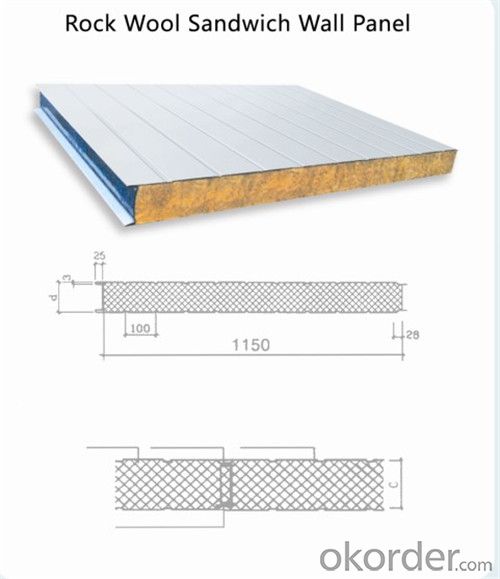

The usual sandwich panels include rock wool Sandwich panel, EPS sandwich panels, PU Sandwich Panel, glass fiber sandwich pannels. The up & down surface of this panel is Galvanized & Prepainted steel sheets, core material is rock rood, EPS, PU, and glass fiber. It is formed by heating, foaming & laminating. It is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Specifications

(1)Core Material: Rock Wool, EPS, PU; Surface Materials: Galvanized Steel sheets or Prepainted Steel sheets.

(2)Wall Thickness: 40, 50, 60, 80,100,120,150,180,200,250mm

(3)Max. Width: 1200mm

(4)Length: according to client's demands, engineering requirements and shipment conditions

(5) Application: for ceiling & wall, partition wall

(6) Widely used in common steel structure and storey adding projects,e.g. adding storey to small steel structure industrid factory building worehouse,suburbon temporary office,residentid quarters,school,hospital,etc.

Characteristics

1) With a light weight, a giraffe fitting and random incise characteristic, the fitting is much simpler, and it can advance the benefit and save the time limit for a project

2) Color coated sandwich panel's surface material and heat preservation material are non-burn or hard-burn materials, entirely satisfy the fireproofing criterion request

3) Manifold disquisition and oversea used approving more than 40 years. By especial coated dispose, the color coated steel panel's guaranty is 10-15 years, and the panel's life express 35 years by painting the antisepsis material after each 10 years

4) Pressing steel panel with the clear line, and many colors for choice, and suit with any different building style materials, achieving the satisfying effects.

5) In common use heat preservation materials are rock-wool, polystyrene,

polyurethane, all with lower thermal conductivity and favorable heat preservation and heat insulation effects

6) Sound insulation intension can be 40-50dB, it is the most effective sound insulation material

7) Pressing steel panel can be arbitrariness incise, it can satisty the especially design demands

8) Use the high strength steel panel for the base metal (contradict open and pull intension 5,600kg/cm2), adding the most advanced design and roll pressing moulding, it gets the best structure character

9) Improves speediness and springiness designs according to clients' requirements.

- Q: What are the considerations for designing steel structures in areas with high seismic hazard?

- When designing steel structures in areas with high seismic hazard, there are several considerations that need to be taken into account to ensure the safety and stability of the building. These considerations include: 1. Seismic design codes and regulations: It is crucial to comply with the local seismic design codes and regulations established by the governing bodies. These codes provide guidelines for designing structures that can withstand the expected level of seismic activity in the area. 2. Site-specific seismic hazard assessment: Conducting a thorough site-specific seismic hazard assessment is essential. This assessment includes studying the local geological and tectonic conditions, determining the maximum expected earthquake magnitude, estimating ground motion parameters, and identifying site-specific hazards such as liquefaction or landslides. 3. Structural analysis and design: The design of steel structures should consider the dynamic behavior of the building during an earthquake. Structural analysis techniques, such as modal analysis and response spectrum analysis, are utilized to evaluate the response of the structure under seismic forces and determine the appropriate design criteria. 4. Ductility and energy dissipation: Steel structures should be designed to exhibit ductile behavior during an earthquake. Ductility allows the structure to absorb and dissipate seismic energy, preventing sudden failure and reducing the potential for collapse. This can be achieved through the use of special steel moment-resisting frames or steel bracing systems. 5. Connections and detailing: Proper connection design and detailing are crucial for ensuring the integrity of the structure during an earthquake. Connections should be designed to accommodate the expected displacements and deformations of the structure while maintaining their strength and integrity. Special attention should be given to beam-column connections and the anchorage of the structure to its foundation. 6. Geotechnical considerations: The interaction between the structure and the underlying soil plays a significant role in seismic design. Geotechnical investigations should be carried out to assess the soil conditions and determine the appropriate foundation design, taking into account factors like soil liquefaction, soil amplification, and potential slope instability. 7. Quality control and construction practices: Proper quality control measures and construction practices are vital to ensure the integrity of the steel structure. Regular inspections, material testing, and adherence to construction standards are essential to guarantee that the structure is built according to the approved design. In conclusion, designing steel structures in areas with high seismic hazard requires a comprehensive understanding of the local seismic conditions, compliance with seismic design codes, and the implementation of appropriate structural analysis, connection design, and construction practices. By considering these factors, engineers can create robust and resilient steel structures capable of withstanding the potential seismic forces.

- Q: Can steel structures be designed with water storage tanks?

- Yes, steel structures can be designed to incorporate water storage tanks. Steel is a versatile and strong material that can provide the necessary support and durability for water storage tanks, making it a suitable choice for such structures.

- Q: How are steel structures resistant to fire?

- Steel structures are resistant to fire due to the unique properties of steel as a construction material. Firstly, steel has a high melting point, typically around 1370 degrees Celsius. This means that it can withstand extremely high temperatures without losing its structural integrity, unlike other materials such as wood or concrete. Additionally, steel does not burn or contribute to the spread of fire. While other materials may ignite and fuel the fire, steel remains unaffected and does not release any harmful gases or smoke. This characteristic helps prevent the fire from spreading to other areas of the building and allows for easier evacuation of occupants. Furthermore, steel structures are often designed with fire protection measures in place. These can include fire-resistant coatings or fireproofing materials applied to the steel members. These coatings can provide an additional layer of protection, delaying the steel's exposure to high temperatures and allowing more time for evacuation or firefighting efforts. Lastly, steel's strength and durability allow it to maintain its load-bearing capacity even in the event of a fire. This means that the structure can withstand the additional weight and stress caused by firefighters and equipment during fire suppression activities. Overall, the combination of steel's high melting point, non-combustible nature, fire protection measures, and structural strength make steel structures highly resistant to fire, ensuring the safety of occupants and minimizing damage to the building.

- Q: How are steel reinforcement bars manufactured?

- Steel reinforcement bars, also known as rebars, are manufactured through a process called hot rolling. It involves heating billets, which are semi-finished steel products, to a high temperature and then passing them through a series of rolling mills. These rolling mills shape and compress the heated billets into the desired size and shape of rebars. The resulting rebars are then cooled and cut to the required lengths before being bundled and shipped to construction sites for reinforcement purposes.

- Q: How do steel structures provide flexibility for future modifications or expansions?

- Steel structures provide flexibility for future modifications or expansions due to their inherent strength and durability. Steel can easily be modified or expanded by simply adding or removing sections, making it easier and more cost-effective compared to other construction materials like concrete or wood. Additionally, steel structures can support heavy loads, allowing for the addition of extra floors or extensions without compromising the overall integrity of the building. The versatility and adaptability of steel make it an ideal choice for future modifications or expansions in various construction projects.

- Q: What are the considerations for designing steel storage tanks?

- When designing steel storage tanks, several important considerations need to be taken into account. These include the intended use and contents of the tank, such as whether it will store liquids or gases, as well as the required capacity and dimensions. Additionally, factors like the environmental conditions, such as seismic activity or wind loads, must be considered to ensure the tank's structural integrity. Other considerations include the selection of suitable materials, corrosion protection measures, and compliance with relevant industry standards and regulations.

- Q: How do steel structures handle soil settlement and subsidence?

- Steel structures are designed to handle soil settlement and subsidence by providing a rigid and stable framework. The use of steel allows for flexibility and resilience, allowing the structure to adjust and distribute the load evenly, minimizing the impact of settlement and subsidence on the overall integrity of the building. Additionally, proper foundation design and construction techniques, such as deep pilings or reinforced concrete footings, are employed to mitigate any potential issues and ensure the stability of the steel structure.

- Q: What are the design considerations for steel airports?

- Some of the key design considerations for steel airports include the structural integrity and strength of the steel framework, the ability to withstand extreme weather conditions, the incorporation of efficient and flexible space planning, the integration of sustainable and energy-efficient systems, and the aesthetic appeal of the airport design. Additionally, factors such as ease of construction, durability, and cost-effectiveness also play a crucial role in the design considerations for steel airports.

- Q: What are the considerations when designing steel structures for power generation plants?

- When designing steel structures for power generation plants, several crucial considerations must be taken into account. Firstly, the structural integrity and safety of the steel framework must be prioritized to withstand the heavy loads and dynamic forces generated by the equipment and machinery. Additionally, the design should account for the specific requirements of power generation plants, such as accommodating large equipment, ensuring proper ventilation, and providing access for maintenance and inspections. The steel structure should also be designed to withstand corrosion and other environmental factors, as power plants often operate in harsh conditions. Finally, cost-effectiveness and efficiency should be considered, aiming to optimize the use of steel and reduce construction and maintenance costs while maintaining high-quality standards.

- Q: How are steel structures designed to accommodate for differential settlement?

- Steel structures are designed to accommodate for differential settlement by using flexible connections and adjustable supports. These design features allow the steel components to move independently and adjust their positions, reducing the impact of differential settlement on the overall structure. Additionally, engineers may also incorporate additional measures such as flexible joints or expansion joints to further mitigate the effects of differential settlement on steel structures.

Send your message to us

Sandwichpanel Prefabricated House | Camp House Sandwichpanele

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords