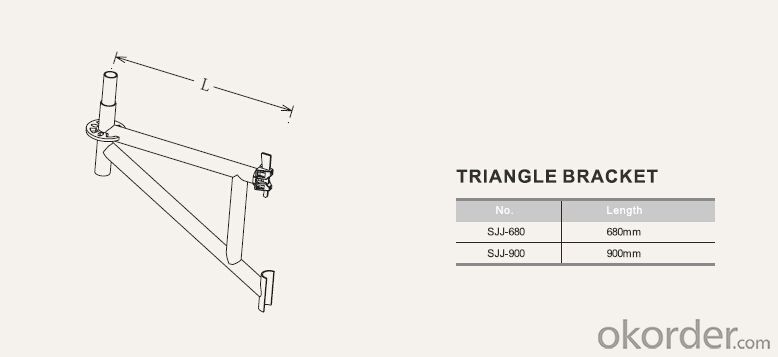

Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

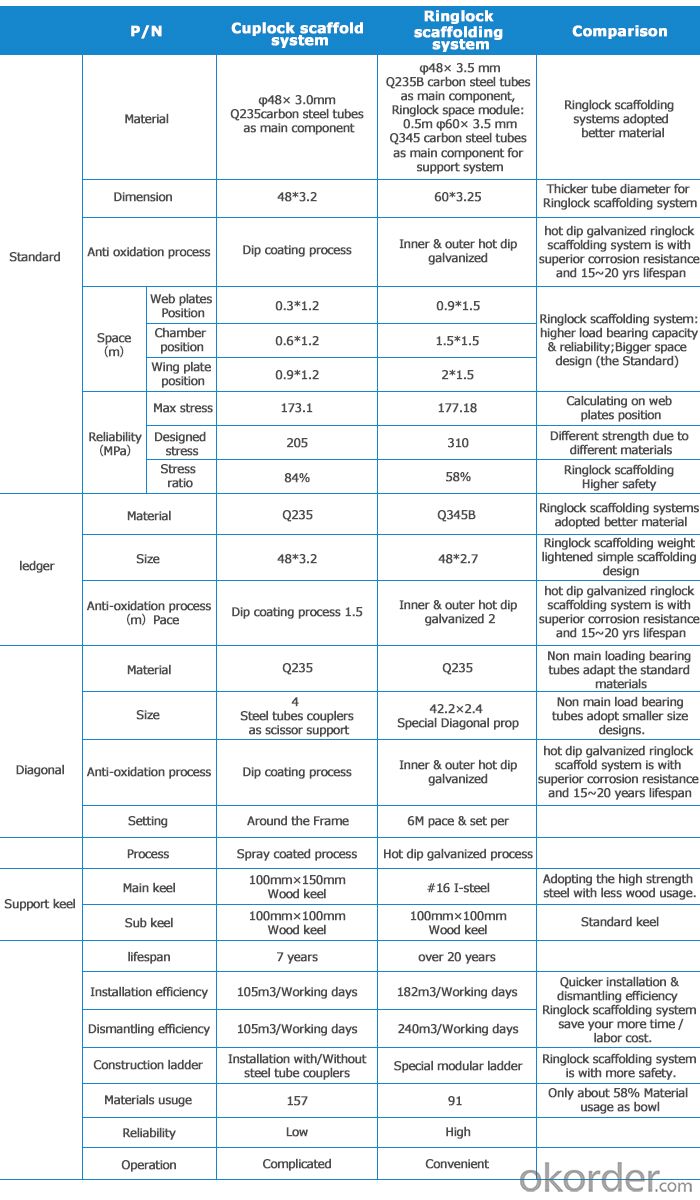

Quick Details of Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm

Material :Q235 carbon steel

Surface treatment :Hot dip galvanized

Length :600MM/900MM

Thickness :2.4MM/2.5MM/2.75MM/3.0MM/3.25MM

Descriptions of Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm

The ringlock Scaffolding and ringlock support system are popularly used in building construction, outside form, cast - in - situ beam, formworks support, canopy frame, bridge & tunnel, stage construction applications and welcomed by building construction companies, construction & decoration companies, leasing companies, media & advertising companies and other users。

Our patented Ringlock Scaffolding and Ringlock support system with surface galvanizing process provided the buyers with higher safety & benefits. Annual output: 7000 tons.

The strong ringlock scaffold system is with 2~3 times installation & dismantling efficiency higher than the cuplock scaffolding system, but only with half steel usage and 75% investment cost.

Our low cost & high benefits Ringlock Scaffolding System with hot dip galvanized surface treatment are easy to installation & disassembly.

Our Ringlock Scaffolding and Ringlock support system with 200 KN high loading bearing capacity are buyers’ safe & professional choice.

Patented R&D and production single personal installation with a hammer only. Greatly saved the steel usages compared to steel tube with couplers.

Details of Tri-angle Brackets

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Cantilever scaffold technical disclosure

- The surface of the steel pipe shall be straight and smooth, and shall not be used for cracks, scarring, delamination, dislocation, hard bending, burrs, indentation and deep drawing.

- Q: Key points for safety of portal scaffolding

- 2, take off the scaffolding workers must wear a helmet, wearing a seat belt, wear non slip shoes.3, the construction load should meet the design requirements, shall not overload; shall not be stacked on the scaffolding template, steel and other objects. Prohibited in the scaffolding on the pull cable wind rope or fixed, erection of concrete pump, pump and lifting equipment etc..

- Q: Want to rent the scaffolding in the county, you need to cast how much money

- A portal scaffolding about 200, a steel springboard around 50,

- Q: How to maintain the scaffold after use

- Where the bending, deformation of the rod should be straightened, damaged components should be repaired before they can be stored in storage, or should be changed.

- Q: scaffolding piercing.. do they hurt? and how much are they in england? thanks x?

- Yes they hurt but like all piercings if you look after them then it wont hurt for long. If you don't like pain don't get them. I can't tell you what they cost in England as you posted your question in the Australia section.

- Q: Electric basket accessories are generic

- Electric basket full name is called electric gondola, the construction of electric basket is mainly suitable for high-rise buildings on the electric power from the electric hoist special basket, basket accessories have what those:

- Q: What are the common rules for calculating the amount of scaffolding works

- The independent brick (stone column) less than 3.60M in height, scaffold to construct the core column multiplied by the circumference of high calculation, the implementation of masonry scaffolding in the shelf; column 3.60M with column wise, the structure of the circumference of the core column height calculated by multiplying plus 3.60M, the implementation of masonry scaffolding outside the shelf (single row). Where masonry height exceeds 1.5m of the masonry are required to calculate the scaffolding.

- Q: What is the service life of the mobile scaffolding accessories?

- In actual use, there are a lot of mobile scaffolding accessories because of deformation, and other reasons, resulting in a lot of scaffolding accessories are not easy to use, or even eliminated. Therefore, the overall life of about 5 years. Therefore, the use of mobile scaffolding accessories should pay attention to the maintenance, so that its useful life to get more, the value of the use of more perfect.

- Q: So im a guyAnd I might get oneAnyone had one before/got one?Any advice?How much do they normaly cost?if you answer this i will love you forever :)

- My industrial was the biggest nightmare piercing I've ever had. I just retired it a few weeks or so ago after waiting for it to heal for 13 months. They usually take between 6 and 12 months to heal. It never healed completely. I got keloids on the inside and outside of both holes and they looked absolutely terrible. I was actually embarrassed when people asked to see my piercing. I couldn't sleep or use the phone or use headphones on that side of my head. Changing the jewelry to titanium only made it worse (and titanium usually does wonders in my piercings). It was the most finicky and miserable piercing I have ever had. Mine was not done with one needle. That is an improper piercing technique. The second hole does hurt like heck, though. Also, don't over-clean it. Twice a day is sufficient. Sea salt soaks are amazing, too!

- Q: Fastener type steel pipe scaffold composed of which components?

- 3.2 fasteners3.2.1 fasteners shall be made of malleable cast iron or cast steel, the quality and performance shall be in accordance with the current national standardRegulation of GB15831 for pipe scaffold fastener. Fasteners made of other materials shall be tested and verifiedQuality meets the requirements of this standard before use.3.2.2 fasteners in bolt tightening torque to 65N * m, shall not be damaged.

Send your message to us

Ringlock System Tri-angle Bracket with Rosete 48*3.2*900mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords