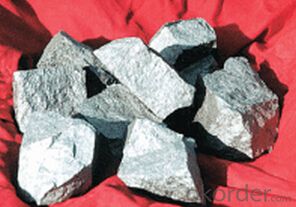

RE FeSi For Casting Manufactural

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1 Type: 15#

2Size: 48mesh 200mesh 48D 270D 0-3mm

3We can do CIQ & SGS quality certification according to customer requirement

Applications

1 Milled Ferro Silicon 15# is a magnetic ferro silicon produced in electric arc furnaces and subsequently milled to size ranges required. In addition, Milled Ferro Silicon contains aluminum and titanium which enhances its resistance to corrosion.

2 Milled Ferro Silicon 15# is used in slurry density applications for heavy media separation and sink-float processes. Powdered Ferro Silicon is an accepted medium for the gravity separation of minerals, aggregates and metals with a specific gravity of approximately 2.0 to 4.0.

3 Milled Ferro Silicon 15# is used extensively in the dense media separation process in both the metal recycling and mining sectors.

Chemical Content

FE | Si | Ti | Al |

70-85% | 12-18% | 0-8% | 0-3% |

Data Sheet

Product Designation(mesh) | +48 | +65 | +100 | +150 | +200 | +325 | -325 | ||

Particle Size(micron) | Percentage by mass | ||||||||

48MESH | 0-6 | 0-8 | 6-14 | 14-22 | 17-25 | 22-30 | 14-22 | ||

65MESH | 0-4 | 0-6 | 3-11 | 11-19 | 15-23 | 25-33 | 23-31 | ||

100MESH | 0-2 | 0-4 | 0-6 | 80-90 | 0 | 0 | 0 | ||

200MESH | 0 | 0-2 | 0-2 | 0-4 | 4-12 | 30-80 | 0 | ||

48D | 0 | 0-2 | 1-9 | 10-18 | 14-22 | 27-35 | 27-35 | ||

65D | 0 | 0 | 0-2 | 0-6 | 4-15 | 29-33 | 47-55 | ||

100D | 0 | 0 | 0-2 | 0-3 | 0-7 | 25-33 | 61-69 | ||

150D | 0 | 0 | 0-1 | 0-1 | 0-4 | 16-24 | 73-81 | ||

270D | 0 | 0 | 0 | 0-1 | 0-3 | 5-13 | 85-93 | ||

0-3MM | -- | -- | -- | -- | -- | -- | -- | ||

- Q: Carbide according to the structure of the words, what can be divided into?

- Cemented carbides are classified into coarse particles, cemented carbides, medium grained cemented carbides, fine grain cemented carbides, fine grain cemented carbides, ultrafine particles cemented carbide, nano particle cemented carbide. Specific, you can refer to Zhuzhou Jing Jing official website

- Q: What are the well-known brands of cemented carbide materials at home and abroad?

- Domestic mainly Zhuzhou, the other side, the 601 factory is the best made in Zhuzhou. That is, the Taiwan side of the spring insurance is equal to the domestic better, and even better point is the German Lu Sheng Fort I know these, ha ha!

- Q: Why is carbide cutting tools less standard than high speed steel cutting tools?

- Because the hard alloy material rigidity is better, the brittleness is bigger, the toughness is relatively bad, namely is easier than the high speed steel cutting tool to break off, after grinding blunt, the force is more complex. Greater resistance. Do you want your expensive tool to break?.

- Q: Explain from the materialGeneral modelIf you buy itWhat parameters are provided?

- Tungsten is on the hard alloy with tungsten carbide as the main (academic called tungsten based alloys), we called the daily hard alloy is usually tungsten based alloys, namely tungsten steel.

- Q: What are the advantages of carbide V-CUT knives and diamond V-CUT knives?

- Precision machining, high finish, sharp blade, machining V groove surface smoothness, no burr burr, greatly improve product quality.Polycrystalline diamond V-CUT knife is now used more and more, and its advantages are: hardness is higher than hard alloy, longer service life, especially in the CNC V-CUT Slitter, the use of good results.

- Q: I would like to use carbide cutting tools, car work, ordinary A3 steel or 45 steel, lathe speed to play more appropriate, the workpiece surface quality is better?

- My car operation for more than 8 years, according to your car parts, actually hit 600 on the coarse, fine car or 1600 rpm, finish good, cutting speed is not too fast, the general lathe is mid-range open 6 can, keep your car parts after.

- Q: What kind of industry can use carbide?

- Coal, steel rolling, non-ferrous metal rolling, mechanical processing.

- Q: How are cemented carbides separated from the cutting tools?

- Brazing heating to melt after the pain, you can take off!

- Q: What are the types and types of carbide inserts?

- There are too many blades, just a few examples of YG3 (used in cast iron, non-ferrous metals and alloys, precision cars or semi fine cars)YT14 (for carbon and alloy steel, semi fine and precision cars)YW1 (applicable to heat resistant steel, high Menggang, stainless steel processing, can also be used for general materials)

- Q: What does "YC20.1 carbide" brand mean?

- PriceFor example, the ordinary 20 party 90 degrees welding tool used A320 blade, the price of 11 yuan, non tax written price /20120716 Edition

Send your message to us

RE FeSi For Casting Manufactural

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords