Low Carbon -Ferro-Manganese CO2 Chinese Cargo

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Carbon -Ferro-Manganese CO2 Chinese Cargo

Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

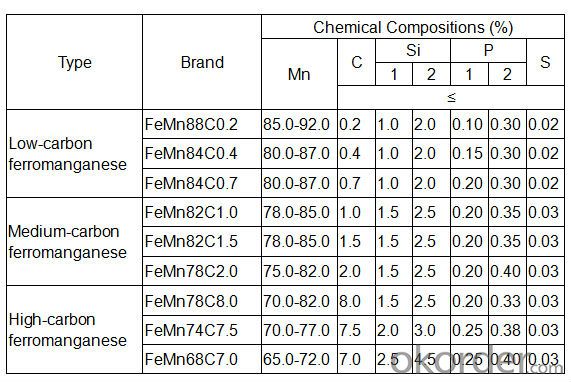

The specification and size:

Can be made as your demand.

Usage:

Metallurgy

PICTURES:

- Q: Where can I buy more than 94 hardness carbide cutter head, welding, the best address in detail, thank you!

- It's no problem to weld cemented carbide. Please call me when you need it

- Q: Carbide yk20? What do you mean?

- Cemented carbides YK20, Y represent alloy categories - tungsten cobalt, K20 represents cobalt contentDensity g/cm3:14.30-14.60;The hardness of HRA is more than or equal to 86.5;The shear strength is greater than or equal to N/mm2:2350,Performance and usage: with high toughness and wear resistance, suitable for embedding percussive rotary drilling bit, drilling in hard and tight hard rock.

- Q: I would like to solder a carbide tool now, what materials do you need to ask for specific methods?

- Just give you a guide to carbide cutting tools, and you'll see

- Q: Dalian enterprises now need 16.3 and 19.3 mm in diameter, the whole cold hard alloy bit, where can I find buyers? Leave a contact

- I know Zhuzhou Hua tungsten seems to have what you need. I suggest you go to see their company

- Q: We'll drill on the stainless steel column. Which bit is better?

- If it's cylindrical carbide, it's better to be on the drill bit or as a guide

- Q: What are the advantages of carbide V-CUT knives and diamond V-CUT knives?

- Hard alloy cutter V-CUT V-CUT also known as tungsten steel knife, V-CUT knife is a highly cost-effective high quality, the overall use of hard alloy is refined, the hard alloy is a kind of tungsten cobalt powder by formula + mixture by pressing sintering of cemented carbide wafer using high quality carbide hard alloy, and then by the advanced precision grinding machining the tool made.Diamond cutting tools are relatively hard and have a hardness of 8000HV.

- Q: The milling of hard cutting workpiece hard alloy cutter knife edge collapse and Countermeasures of reason

- Hard to turn materials require different speeds and special turning tools. There is a reasonable amount of feed. Ordinary alloy knives are very easy to break

- Q: What are the types of cemented carbides?

- Hello, the carbide tools are divided into the following categories:1, the whole hard alloy tools, including drill, milling cutter, reamer, boring, milling, ball milling, milling cutter, taper cutter, plug gauge, round bar and step drill.2 、 insert alloy cutting tools, including reamer, spiral end milling cutter, drill expanding cutter, automobile hub knife, three face edge, T type milling cutter and various forming knives.

- Q: belong to raw material? After buying instockroom directly under the workshop to account for 5The company is small, no warehouse, do not fill in a single storage, the parts purchased directly to use, how to do?It's so complicated. Is there a simple way to do it?

- Carbide grinding head, drill bit, tap, is a tool of low value, easy to wear goods.Welding wire, flux, welding rod and protective welding gas belong to raw material

- Q: Hard alloy and cast iron join together, use temperature 150 degrees, what glue is better to use?

- Why use glue only? Recommend the use of welding, as welding tool is not the same as you can.

Send your message to us

Low Carbon -Ferro-Manganese CO2 Chinese Cargo

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords