Good Quality Ferro-Manganese for Sale Chinese Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good Quality Ferro-Manganese for Sale Chinese Supplier

Usage of Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

Introduction:

It used the high quality anthracite as raw materials through high temperature calcined at over 2000 by the DC electric calciner with results in eliminating the moisture and volatile matter from anthracite efficiently, improving the density and the electric conductivity and strengthening the mechanical strength and anti-oxidation. It has good characteristics with low ash, low resistvity, low sulphur, high carbon and high density. It is the best material for high quality carbon products.

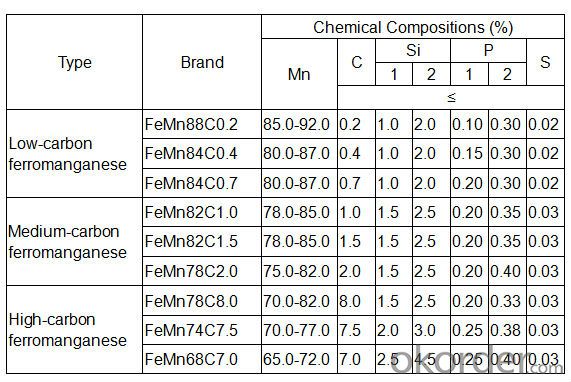

Specification of Ferro manganese

The specification and size can be made as your demand.

PICTURES:

- Q: The difference between carbide knife and white steel knife

- 3, hardness is not the same: cemented carbide hardness, especially at high temperature hardness, but high-speed steel toughness better4, can withstand the cutting speed is not the same: due to the red hard high, can withstand higher cutting speed, and high-speed steel is now not high speed

- Q: CNC alloy milling cutter how to produce?What is the cutting edge of the machine tool?What is the surface coating?What is the cost of plating?Prawns talk about it in detail, I do alloy accessories, I would like to learn some processing methods ~ ~!

- The price varies from a few thousand dollars to a few days depending on the size of the blade and the specificity.Surface coating is usually coated with titanium (such as titanium nitride, etc.)Large manufacturers such as diamond coating equipment general equipment in the tens of millions of yuan in cost is quite high, in Jiangsu there is a foreign company specialized in coating equipment sold to undertake external coating business, the coating cost with you a coated blade is related to the price from a few dollars to tens of dollars / piece / slice.

- Q: What are the grinding carbide wheels?

- Diamond grinding wheel, carborundum wheel. Only welded blades use carborundum wheels, and generally fine grinding blades use diamond grinding wheels.

- Q: Carbide die how to calculate weight, that is to say, its kg weight

- The density of tungsten, cobalt and titanium carbide is 9.7~13.2, and the higher the content of titanium carbide, the lower the density.

- Q: How to distinguish the authenticity of Zhuzhou diamond brand cemented carbide blade?

- In fact, now only look at the packaging has been unable to identify, because now the copycat alloy packaging has really not with what two things, want to know after the authenticity can be used, you can try to buy a small amount of alloy, the quality of clearance to buy a lot, you can go to the station to find the Alibaba China @ Rui Sen # trade. Easy% Co., reputation has been good, but sales of hard alloy Zhuzhou diamond factory, there are quality problems can return shipping.

- Q: What kinds of carbides are there? How should we choose in production?

- Basically divided into four major categories: YG, YW, YS, YT.YG is cast iron, nonferrous metal, base alloy steel.YW is made of stainless steel and base alloy steel.YS is the finishing of high strength steel, steel and cast steel.YT is the rough processing of steel and cast steel.

- Q: 5 meters long hard alloy bars, where are they sold?

- Because of being restricted by the conditions of equipment for the production of hard alloy long alloy strip production generally more difficult, even if the production price is not expensive, you can consider the method of sectional concrete can look at Zhuzhou with a hard alloy.

- Q: Is the hard alloy the same as the cemented carbide?

- Is essentially the same, are two kinds of powder alloy materials, but the composition is different, its processing performance depends on the alloy material of concrete, in my experience, super hard alloy toughness than hard alloy with high hardness, but lower than the hard alloy, don't be misled by the literal meaning, the word super tool hard alloy generally refers to add the other ingredients of high speed steel the hardness wear resistance than ordinary high speed steel (of course not hard alloy) without losing the advantages of high speed steel toughness.

- Q: What about cemented carbide produced in Zhuzhou? What brand is good?

- Diamond brand still has a certain position, the 1 floor said that the fine carbide sales company, I pass there every day, but also put Alibaba lights in there

- Q: Import all carbide drill bit, mainly those brands

- Good (maford), Kenna, Thomas, di tex, Sandvik, guhring general in the domestic production, the performance of discount.Now on the market is generally a bit alloy steel material whole bit, although the materials are the same, but due to the processing technology, various brands of product quality disparity. Imported and domestic alloy drills are also very different.Imported alloy bit usually adopts VHM micro grain hard alloy (ISO K40), the type of ultrafine particles (0.6 m) in the application of high performance drill and ordinary milling machine, the hardness and toughness of the ideal together.Take high quality alloy bit surface coating, such as chromium aluminum nitride (AlCrN) coating, the coating layer of coating, the thickness of 4 m, the micro hardness is up to 3200HV, the friction coefficient of 0.35, thermal stability up to 1100 degrees celsius. After coating, the drill color is bluish gray.After coating, the alloy drill can process low alloy steel and high strength steel. High steel can reach 54HRC.

Send your message to us

Good Quality Ferro-Manganese for Sale Chinese Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches