low Carbon -Ferro-Manganese C0.4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

The specification and size can be made as your demand.

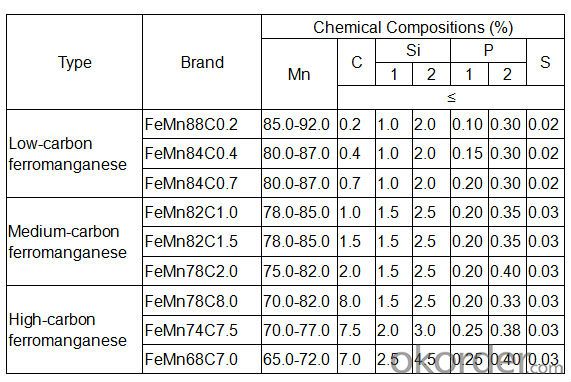

PICTURE

- Q: What is the resistivity of the yg13 cemented carbide?

- Two, production processProportioning, mixing, crushing, drying, fully add sifted molding agent, then drying and sieving to prepare a mixture, pressing, mixing and granulating (Germany imported vacuum pressure sintering furnace), low pressure sintering and sintering the blank test after (nondestructive ultrasonic inspection), blank size accuracy test.

- Q: Chengdu which has carbide scrap acquisition point?

- What alloy do you have? A lot of home cash recycling, big price worries, good faith cooperation! This site in Jinniu District this way

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- You should be a 8 mm tungsten steel milling cutter, the speed should be controlled below 2200 to 3000, because the speed and your cutting are related to the amount of advice:

- Q: How many models are there? 10Because we want to purchase carbide milling cutters, we would like to know the classification methods and the characteristics of various types of carbide at home.Some people say that Zhuzhou is best, Nanchang, Fujian, Longyan in turn. But there are many factories in a region. How can you say which is good and that is not good?Do you have a YL model?

- Overall, Zhuzhou cemented carbide works, Shanghai alloy materials factory, Zigong cemented carbide plant, new carbide knives are good. But the single pair of milling cutters is not clear! There is no YL!

- Q: High end markets for cemented carbides

- Chinese tool enterprises through continuous learning and strategic planning, has occupied half of the country, but in the market, enterprises in the development process and highlights several fatal problems, such as inadequate attention, improper handling, all these will seriously affect the development of enterprises.At this stage, carbide cutting tools in developed countries have accounted for the dominant position of the tool type, the proportion of up to 70%.

- Q: It is hard alloy steel

- Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q: The welding welding hard alloy cutter, should use what type of flame why

- With the fire on it. Put the knife and put some red hot and then put up with borax alloy outer flame burning red and then placed in a good point copper alloy and borax on the use of knife gap flow with upper and lower outer flame burnt gap can be

- Q: The difference between cemented carbide and tungsten.

- Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q: YW2 carbide blade type

- YW2 general cylindrical turning tool head type: A325 20pcsCemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q: Where can I use cemented carbide?

- Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Can be used to make drilling tools, mining tools, drilling tools, measurement tools, wear parts, metal grinder, cylinder liner, precision bearings, nozzle, metal mold (such as wire drawing dies, molds, mold, nut bolt fasteners and various molds, carbide goodnature can gradually replace the steel mold before).Carbide mainly YT, YN, YW and YG series, according to the different properties applied to different fields.

Send your message to us

low Carbon -Ferro-Manganese C0.4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords