High Carbon Ferro Chrome Factory Supply with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Carbon Ferro Chrome Factory Supply with Best Price

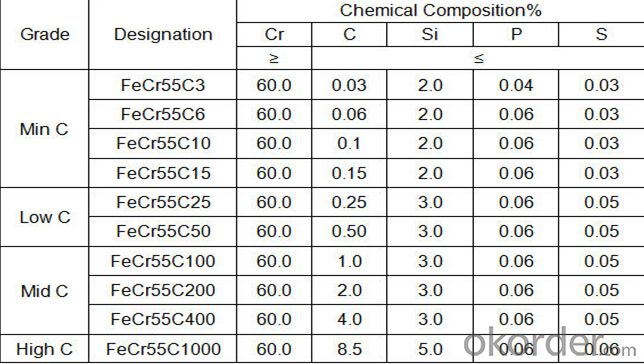

Specification of Ferro Chrome:

Pictures of Ferro Chrome:

Product Description

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: hard alloy ball tooth, sand making machine, high quality and inexpensive alloy (*^__^*)I am now in great demand of cemented carbide rods, hard alloy blade, hard alloy ball tooth, sand making machine alloy strip, the old customers are not do, now I want to find a long-term cooperation partners, we have not recommended ~ ~ ~ thank you pull

- Hello, I'm from Zhuzhou CREE cemented carbide Co., Ltd.We are specializing in the production of various specifications of hard alloy, Zhuzhou cemented carbide, Zhuzhou hard alloy, sand making machine alloy strip, hard alloy ball tooth, carbide blade, hard alloy bars, welding blade, milling cutter, long and thin; manufacturers selling cheaper price; all kinds of hard alloy, Zhuzhou cemented carbide, Zhuzhou hard alloy sand making machine alloy, hard alloy ball tooth, carbide blade, hard alloy bars, welding blade, milling cutter, long and thin, everything, quality assurance; welcome you to come to the consultation, to serve you is our honor.

- Q: Carbide blade domestic that tricky point?

- China's carbide cutting tools must be the best cemented carbide in Zhuzhou.

- Q: Carbide yk20? What do you mean?

- Cemented carbides YK20, Y represent alloy categories - tungsten cobalt, K20 represents cobalt contentDensity g/cm3:14.30-14.60;The hardness of HRA is more than or equal to 86.5;The shear strength is greater than or equal to N/mm2:2350,Performance and usage: with high toughness and wear resistance, suitable for embedding percussive rotary drilling bit, drilling in hard and tight hard rock.

- Q: What brand of carbide is used in woodworking tools?

- The quality alloy YG6X/YG6A is suitable for the processing of chilled cast iron, alloy cast iron, heat-resisting steel and alloy steel. It is also suitable for the fine machining of precision cast iron and the manufacture of wear-resistant parts. Hard alloy YG8N: is suitable for fine cast iron, ductile iron, white iron and non-ferrous metal finishing.

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- Faster, two RPM 1 mm, too fast, with G96 RPM feed 0.2 below

- Q: How many models are there? 10Because we want to purchase carbide milling cutters, we would like to know the classification methods and the characteristics of various types of carbide at home.Some people say that Zhuzhou is best, Nanchang, Fujian, Longyan in turn. But there are many factories in a region. How can you say which is good and that is not good?Do you have a YL model?

- Overall, Zhuzhou cemented carbide works, Shanghai alloy materials factory, Zigong cemented carbide plant, new carbide knives are good. But the single pair of milling cutters is not clear! There is no YL!

- Q: What are the meanings of cemented carbide codes, such as YW, YS30, YN10?Which company made its own brand? What is the composition?

- YW refers to the national standard brand. YS30 and YN10 are made by the company themselves. The brand is made up of the largest cemented carbide producer in China, Zhuzhou 601 (Zhuzhou cemented carbide group).

- Q: Classification of Cemented Carbides

- Cemented carbides are classified into tungsten, cobalt, tungsten, titanium, tungsten, titanium, tantalum and cobalt. Tungsten cobalt carbide knife with: YG6, YG8, YG8N and so on, such carbide cutting tools for processing non-ferrous metals, stainless steel, cast iron and other materials;Tungsten carbide hard alloy knife has: YT5, YT15, etc., this kind of carbide cutting tools for processing steel and other tough materials;Tungsten, titanium, tantalum, cobalt carbide knife with: YW1, YW2, YS25, WS30, etc., this kind of carbide cutting tools for processing heat-resistant steel, high manganese steel, stainless steel and other difficult materials.

- Q: Dalian enterprises now need 16.3 and 19.3 mm in diameter, the whole cold hard alloy bit, where can I find buyers? Leave a contact

- I know Zhuzhou Hua tungsten seems to have what you need. I suggest you go to see their company

- Q: Model of grinding carbide wheel sheet

- I. model:Generally, diamond grinding wheels are used for grinding carbide, and diamond grinding wheels are usually divided into diamond size. Model 400 is fine.Two. Brief introduction of grinding wheel:Also called consolidation abrasives, grinding wheels are bonded by the bond of ordinary Abrasives into a certain shape (most round, central through hole), and has a certain strength of the consolidation of abrasives. It is generally made up of abrasives, binders and pores. These three parts are often called the three elements of the bonded abrasives. In accordance with the different classification of binders, there are common ceramic (bond) grinding wheel, resin (bond) grinding wheel, rubber (bond) grinding wheel. The grinding wheel is one of the largest amount of abrasives, widely used, when using high-speed rotation can be cylindrical, metal or nonmetal workpiece inner circle, plane and various surface of rough grinding, semi fine grinding and fine grinding and notching and cutting etc..

Send your message to us

High Carbon Ferro Chrome Factory Supply with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords