Chinese High Quality High Carbon Ferro Chrome with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chinese High Quality High Carbon Ferro Chrome with Best Price

Pictures:

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

Specifications

High Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

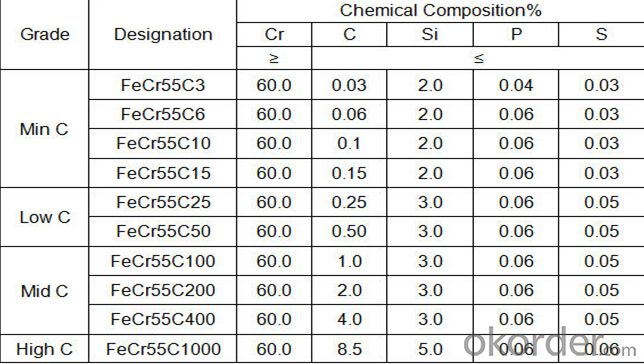

Content information

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q:Method for assembling hard alloy cold heading die

- If it is made of hard alloy cold die core and the steel bushing assembly, depends on the heat treatment hardness you cold die steel sleeve to be, if not steel heat treatment, direct heat bushing, the amount of interference for hard alloy core diameter of about 0.6%, if the steel heat treatment to HRC40 about the amount of interference for hard alloy core diameter about 0.3%.

- Q:What does "YC20.1 carbide" brand mean?

- PriceFor example, the ordinary 20 party 90 degrees welding tool used A320 blade, the price of 11 yuan, non tax written price /20120716 Edition

- Q:Is the hard alloy the same as the cemented carbide?

- The CBN price is a little high. If you can't accept it, you can consider using the ceramic cutter to test the PCBN (CBN) blade. Ceramic blades can not work (he is brittle, easy to crack), super hard tool sales

- Q:How are cemented carbides separated from the cutting tools?

- Brazing heating to melt after the pain, you can take off!

- Q:How are cemented carbides sintered?

- Raw materials according to the provisions of the proportion of added alcohol or other medium in the wet ball mill in wet grinding, making them fully mixing, crushing, drying, sieving after adding wax or gel forming agent of a class, and then drying and sieving to prepare a mixture. Then, when the mixture is granulated and pressed and heated to a point near the bonding metal (1300~1500 DEG C), the eutectic alloy is formed by the hardening and bonding of the metal.

- Q:How are hard alloy fittings machined and polished?

- Cutting tools or ceramic cutting tools for cubic boron nitride material, cobalt alloy cutting tools, etc.,Diamond grinding materials for polishing.

- Q:What are the cemented carbides?

- For example, YT15, which represents average TiC=15%, is tungsten carbide cobalt carbide with the remainder of tungsten carbide and cobalt content.Tungsten, titanium, tantalum (niobium) carbidesTIC cutterIs the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.The grade by "YW" ("hard", "million" Pinyin prefix) and sequence number, such as YW1.

- Q:What is the base material of carbide saw blade?

- Carbide saw blades include the kinds of alloy cutters, matrix materials, diameter, tooth number, thickness, tooth shape, angle, aperture and so on. These parameters determine the machining ability and cutting performance of saw blades. In selecting the saw blade, it is necessary to select the saw blade according to the kind, thickness, sawing speed, cutting direction, feeding speed and width of saw.

- Q:What material is that ultrafine cemented carbide?

- You mean the ultra-fine grain cemented carbide, generally we have 0.6 alloy grain size is fine, which belongs to the tungsten carbide base hard alloy, ordinary tungsten carbide base hard alloy strength and hardness are higher than the same cobalt content. The process is mainly mixing, wetting, drying, forming, sintering, finishing, such as sand blasting, CVD/PVD coating, heat treatment, etc.

- Q:CNC alloy milling cutter how to produce?What is the cutting edge of the machine tool?What is the surface coating?What is the cost of plating?Prawns talk about it in detail, I do alloy accessories, I would like to learn some processing methods ~ ~!

- The price varies from a few thousand dollars to a few days depending on the size of the blade and the specificity.Surface coating is usually coated with titanium (such as titanium nitride, etc.)Large manufacturers such as diamond coating equipment general equipment in the tens of millions of yuan in cost is quite high, in Jiangsu there is a foreign company specialized in coating equipment sold to undertake external coating business, the coating cost with you a coated blade is related to the price from a few dollars to tens of dollars / piece / slice.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chinese High Quality High Carbon Ferro Chrome with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products