Medium Carbon -Ferro-Manganese C1.5 CNBM Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Medium Carbon -Ferro-Manganese C1.5 CNBM Supplier

Usage of Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

Introduction of Ferro manganese

Silicon Manganese is produced depending on the resources available, either from silicious manganese ores or from manganese rich slags that are a by-product of Ferro Manganese production. It is used in its own right as an additive in the steel industry as a deoxidant or utilized in the production of other manganese alloys.

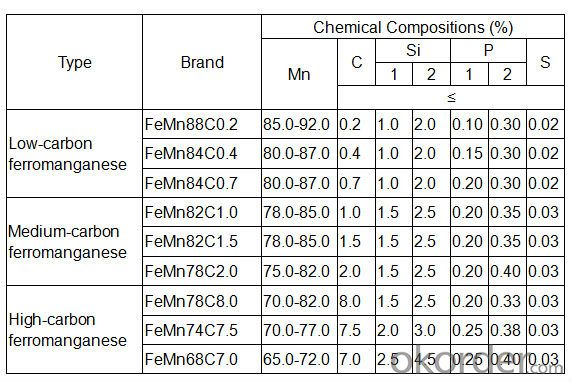

Specification of Ferro manganese

The specification and size can be made as your demand.

Pictures of Ferro manganese

- Q: In addition, the same furnace products out, the standard sample bar is qualified, no hole, but YT14 blade has more holes, why is that ah?

- YT14 alloy you said, if the above holes can start from the following aspects, 1, raw materials, dirty and high oxygen content, impurity content, sintering, 2.If the hole shape of the dirty and dirty, you can see some holes around a circle with cobalt layer, small holes are filled with cobalt, cobalt pool formation, if not pressure, hole like narrow shape.

- Q: Now on the market scrap carbide blade (YG8 milling cutter) how much is one kilogram?

- Now on the market scrap carbide blade about 100 yuan / kg, depending on the alloy composition, trading area and fixed.Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.

- Q: What's the use of recycling cemented carbide?

- Refined tungsten, northern recovery mostly shipped to Hebei, Xingtai.

- Q: Hello I remember carbide knives have several classifications As if it were not the same as it is now, can you tell me the same and different models as before? What material can they make?

- I remember Zhuzhou Hua tungsten. They have a full range of them. You can go to their Baidu company

- Q: One kind of steel is called T10, and another is carbon steel. What kind of hardness and strength do they have?

- Carbon steel is also divided into many kinds, the higher the carbon content, the greater the hardnessAlloy steel is also very many kinds of ah, what tungsten carbon alloy, chromium, manganese, molybdenum and so on a lot?It seems that Chinese steel is not of high qualityTechnology is not in place

- Q: Can ceramic tools process cemented carbides?

- No, ceramic cutters are usually used to process cast iron (high speed machining) and high hardness steel (Cui Huogang).Generally, the hardness of ceramic tools reaches HRA91-95, while the hard alloy can reach HRA93.The main components of ceramic tool materials are Al2O3 with high hardness and melting point. Si3N4 and other oxides and nitrides, and then added a small amount of metal carbide, oxide or pure metal additives, formed by pressing, sintering, and then a tool material. Its hardness can reach HRA91 ~ 95, and the hardness of HRA80 can still be kept at the cutting temperature of 1200 DEG C. In addition, the chemical inertia is large, the friction coefficient is small, and the wear resistance is good, and the service life of the processed steel pieces is 10~12 times of that of the hard alloy.Its major disadvantages are brittleness, low bending strength and low impact toughness. Therefore, it is mainly used for semi finishing and finishing, high hardness, high strength steel and chilled cast iron and other materials. Commonly used ceramic cutting tools are alumina ceramics, composite alumina ceramics and composite silica ceramics.Taiwan is hard gold metal carbide with high heat resistance and high wear resistance (WC tungsten carbide, titanium carbide, tantalum niobium carbide TiC TaC, NbC etc.) and metal binder (cobalt, nickel and molybdenum) powder metallurgy products under high temperature sintering. The hardness of HRA8 9 ~ 93, 850 ~ 1000 DEG C high temperature resistant, has good abrasion resistance, allowing the use of the cutting speed can reach 100 ~ 300m / min, can be a variety of materials including machining hardened steel, therefore it is widely available.

- Q: Material properties of Cemented Carbides

- Hard alloy with high hardness of refractory metal carbides (WC, TiC) micron powder as the main ingredient, with cobalt or nickel (Co) (Ni), molybdenum (Mo) as the binder, powder metallurgy products in vacuum furnace or hydrogen reduction sintering furnace. IV, B, V, B, VI, B group of metal carbides, nitrides, boride, etc., because of hardness and melting point is particularly high, collectively referred to as cemented carbide. The structure, characteristics and application of hard gold content are described with carbide as the key point. IV, B, V, B, VI, B group metals and carbon formed in the metal type carbide, because the carbon atom radius is small, can be filled in the gaps of the metal lattice, and retain the original lattice form of metal, forming interstitial solid solution. Under appropriate conditions, such solid solution can continue to dissolve its constituent elements until it reaches saturation. Therefore, their composition can change in a certain range (such as the composition of titanium carbide in TiC0.5 ~ TiC changes), chemical formula does not conform to the rules of valence. When the dissolved carbon content exceeds a certain limit (such as titanium carbide in Ti: C=1: 1), the lattice type will be changed, the original metal lattice metal lattice into another form, then the interstitial solid solution called interstitial compounds.

- Q: What kind of cemented carbide is used for processing HRC40 degrees stainless steel?

- It is recommended to choose YS8 welding tool. Very good processing quality can be obtained.

- Q: My uncle is a hard alloy round bar. Can you tell me where to use an alloy round bar?

- I have some hard alloy round bars (tungsten steel) and high speed steel round rods (all used for cutting tools). Now I want wire cutting, laser, diamond, wire cutting

- Q: What are hard alloys? Which ones are they? How often are they chosen?

- Cemented carbide is a hard particle of refractory metals (tungsten, tantalum, titanium, molybdenum, etc.) that is mixed with one or more iron elements (cobalt, nickel, or iron), pressed and molded, and then sintered. Types and properties of cemented carbides: (1) classification and grade of cemented carbides. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide (WC) and binder cobalt (Co). The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average amount of cobalt. For example, YG8 is a tungsten cobalt carbide that represents an average WCo = 8% and the remainder is tungsten carbide. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide, titanium carbide (TiC) and cobalt. The grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide. For example, YT15 represents an average WTi = 15%, while the others are tungsten titanium cobalt carbide with tungsten carbide and cobalt content. The tungsten titanium tantalum (NB) hard alloy is the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.

Send your message to us

Medium Carbon -Ferro-Manganese C1.5 CNBM Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords