High Carbon Ferro Chrome by Leading Supplie CNBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Carbon Ferro Chrome by Leading Supplie CNBM

Pictures

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Specifications

High Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

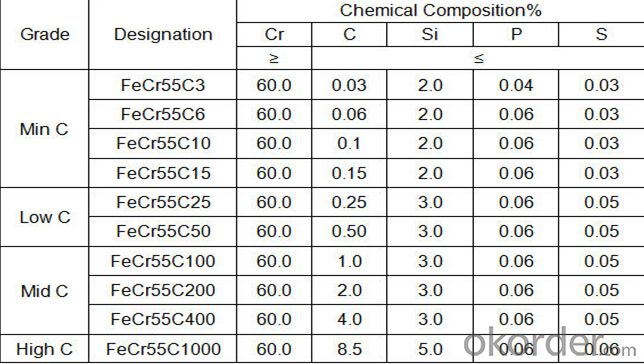

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: Does the hard alloy belong to the composite material?

- It's a composite material made up of dock, titanium and cobalt.

- Q: How to detect carbide material is raw material or recycled material, what is the difference?

- The original material has uniform particle size and stable performance. High priceGenerally, the size of recycled materials is poor, and the finished products are not stable. The price is relatively cheapIn general, carbide factories have specialized testing equipment

- Q: What kind of material is the alloy drill bit?

- Alloy bit generally refers to the hard alloy bit, divided into integral, welded, indexable inserts and replaceable type.The main components of cemented carbide are tungsten carbide, cobalt, etc., the hardness is relatively high, generally above HRC90 degrees, and it is suitable for batch processing and hard processing!

- Q: What is the specific gravity of cemented carbide?

- Similar to mercury. Tungsten cobalt carbide 14.4~15.3 density, tungsten, cobalt, titanium carbide 9.7~13.2 density, can float in the mercury is a steel knife, sink into the mercury is a cast iron knife

- Q: Big brother on the 1 floor is exaggerating. It's impossible at all

- The shrinkage coefficient must be taken into account, but the technical requirement is quite high and the molding is difficultIn the processing of hard alloy threads, if high precision, small hole, can be used in EDM processing, now EDM with C axis, don't work fixture, the thread can play any pitch, as long as the processing thread electrode is.

- Q: Hello I remember carbide knives have several classifications As if it were not the same as it is now, can you tell me the same and different models as before? What material can they make?

- I remember Zhuzhou Hua tungsten. They have a full range of them. You can go to their Baidu company

- Q: Material properties of Cemented Carbides

- Metal carbides, especially B, B, IV V VI B metal carbide melting point is above 3273K, the TAC hafnium carbide, respectively 4160K and 4150K, is the highest point currently know material. Most of the carbide hardness large, their microhardness is higher than 1800kg mm2 (micro hardness is hardness says one way for hard alloy and hard compound, microhardness 1800kg mm2 is equivalent to a diamond a Mohs hardness of 9). Many carbides are difficult to break down at high temperatures, and their antioxidant power is stronger than their constituent metals. Titanium carbide has the best thermal stability in all carbides, and is a very important metal type carbide. However, in an oxidizing atmosphere, all carbides are readily oxidized at high temperatures, which can be said to be a major weakness of carbides. In addition to carbon atoms, nitrogen atoms and boron atoms can also enter the voids of the metal lattices and form interstitial solid solutions. They are similar to the gap carbide in that they can conduct electricity, heat conduction, high melting point, high hardness and great brittleness at the same time. The matrix of cemented carbide consists of two parts: one is a hardening phase, and the other is a bonding metal. Is the hardening phase transition metal carbides in the periodic table of elements, such as tungsten carbide, titanium carbide, tantalum carbide, their hardness is very high, the melting point of 2000 DEG C, and some even more than 4000 DEG C.

- Q: What is the hardness of the carbide thread?

- The hardness of cemented carbide tools is generally between 89~92.8, such as the hardness of YG8 is HRA89, the hardness of YT30 is 92.8, and the hardness of YT15 is 91.

- Q: What are the carbide inserts on the turning tool welded to the handle?

- Burn copper on the knife rest.Pour the borax onto it.Put the alloy blade on it.Borax fell on the alloy blade top with flame cutting money.Be careful not to use the high pressure oxygen valve. Wait until the copper water flows out evenly and cools naturally.

- Q: Where can I use cemented carbide?

- The main application of carbide cutting tools, cutting tools and metal processing in geological drilling, drill and tool in shield construction. Manufacturing cutting tools, cutting tools, cobalt and wear-resistant parts, widely used in military, aerospace, aviation, machinery processing, metallurgy, oil drilling, mining tools, electronic communications, construction and other fields.

Send your message to us

High Carbon Ferro Chrome by Leading Supplie CNBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches