QB Series Peripheral Pumps with Brass Impeller

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application of QB Series Peripheral Pumps:

1> Clean Water without abrasive particles, non-aggressive liquid.

2> Domestic use.

3> In particular for delivering water in combination with small pressure sets and for irrigation.

4> Installed in enclosed places, or at least protected against inclement weather.

2. Operating conditions for QB Series Peripheral Pumps:

1> Suction lift up to 8m.

2> Liquid temperature up to +40℃

3> Ambient temperature up to +40℃。

4> Max. working pressure: 6bar.

3. Motor description of QB Series Peripheral Pumps:

1> 2-pole induction motor: 50Hz.

2> Insulation: Class B.

3> Protection: IP44.

4> With capacitor and thermal overload protection.

4. Material of QB Series Peripheral Pumps:

1> Pump body: Cast Iron.

2> Motor bracket: Aluminum.

3> Impeller: Brass.

4> Shaft with rotor: Stainless steel or CS45#

5> Mechanical seal: Ceramic-Graphite.

6> Copper Winding.

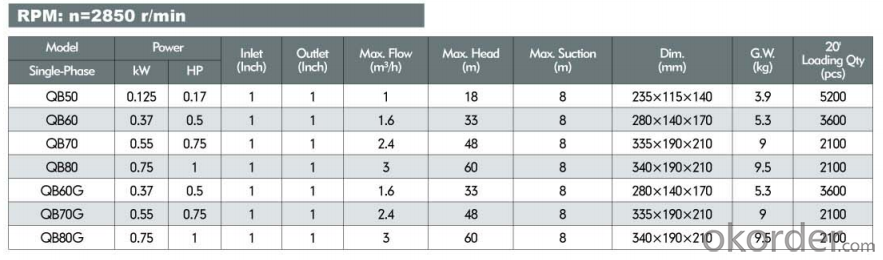

5. Detailed specification for QB Series Peripheral Pumps:

6. FAQ

1). Can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2). Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3). How long is your warranty?

Unless otherwise expressly authorized in writing, by specifying a longer period or different conditions, CNBM states that, for a period of twelve (12) months from delivery date, all Products supplied are free from defects in materials and workmanship, and conform to the applicable specifications. Either the delivery documentation or the invoice must be provided to prove delivery date. In absence of such documents, the production date appearing on the product label may suffice.

- Q: can't get the pulleys to line up I know I have a mid 70's 400 and the water pump is later than 1969 but I can't find a pulley that works every one is about a half inch off I bought a aftermarket set of underdrive pulley's from march performance and still the same problem the water pump is a half inch off there was no long or short water pump right they are all the same lenght right??? The only difference I know of is that pre 1968 the pumps have a 8 bolt design and after they have a 11 bolt design is that right???

- Actually there was two main pumps for the older ones,, one was called a short shaft,,and one was called a long shaft,,the long shaft was the most popular,and it all depends on whether your car had power steering,,and air conditioning on it,,all the ones that used the long shaft usually had air,,and power steering on them also,,also some of them had a smog pump on them,,this was the main reason they used the long shaft,,most of the smog pumps got taken off and discarded down through the years,,but you still had to use the pump that had the long shaft,,this is the problem your having,,i own a repair shop in Tennessee,,and have been redoing some old cars in the past few years i to have run across the same problem you are having,,you can have a long shaft ordered for you ,,and it will work fine,,i had to use the long shaft on the one i was redoing hope this helps some.

- Q: One repair shop on the phone says I will need new water pump, coolant flush and *850.00. On the other hand the dealer says I may need tow other drive belts (alternator +). Second dealer says I may need a water pump! I do not wish to get stuck with extra costs! any one with experience?

- Read your manual. Chances are your camry has treated you very well. Do the same for it. Yes, get a water Pump. It is not that expensive.

- Q: i took off the water pump cover on my 1986 cr 250 and discovered that the impeller wont come off. ive tried turnig it the wrong way and the right way. can someone please tell me how to get it off.

- 1986 Cr 250

- Q: ok so i have a crack in my radiator a small crack but anyways yesterday it caused my car to over heat. i normally keep coolant in the car but it just got low and over heated pretty bad. so today the car is making a really loud annoying noise. coolant is also draining out of the bottom of the engine when the car is on. at a pretty good pace. it is coming out like right under the belt area so my friend said it is probably the water pump baring and he said it could have gotten damaged when it over heated. so i think these symptoms def point to the water pump. anyways i called a mechanic and he said that he had to change the belt to and he said he had to charge me $385. what you guys think. does he need to change the pump and the belt or just the pump? and is $385 a rip off or is that the going rate? thank you all for your knowledgeand information

- Read the above PLUS realize that you MUST use ONLY genuine Toyote coolant in your car. Other coolants will cause further deterioration of your cooling components. I have seen Toyota cylinder heads that look like Swiss cheese from using the green stuff. Also, make sure that your mechanic uses only genuine Toyota replacement parts, and NOT rebuilt pump. Replace the tensioner and idler pulleys now, as well. The price is a rip off if cheaper parts are being used. If these are all factory parts, then this price is GREAT!!

- Q: And if it needs to be replaced, does that spell trouble for a car? I see a car I might like to buy, but the ad says that the water pump needs to be replaced. Someone please enlighten me. Thanks.

- I have been in the automotive cooling business for over 25 years and Michael is exactly right. Depends on the make model and year . Usually normal wear and tear on a car will cause the pump to fail it is a fast moving part but at the same rate have some one point out the cooling systems recovery bottle and look inside of it and take a whiff. If it looks bad and smells bad that could be your sign to move on to the next car. Look for rust colored stuff in the coolant bottle BUT if it is a GM product after 95 i believe they have orange coolant so don't let that through you off either.

- Q: How can I be sure the water pump is the problem before spending $ on repairs. 97 civic overheating.?

- Check the thermostat, if that's the problem you'll be looking at a 5 or 10 dollar bill if you do the work yourself.

- Q: guys i have a mini-water pump.....i wanna pump kerosene instead of water,to make a mini stove,on my own..my doubt is ...if the water pump is used to pump kerosene,will the kerosene ignite inside the pump itself or will cause any problem..i just want the pump to pump kerosene....will it ignite inside of the pump,because the pump runs on electricity....can u clear my doubt

- Is the motor of the pump built-in so that the pumped fluid flows through the motor also? If the answer to the question is yes then do not use the pump for pumping kerosene. However, if the pumped liquid does not come in contact with motor then you can use the pump for pumping kerosene. But ensure that the pump shaft seal is of mechanical type (so that kerosene does not leak from the shaft sealing area) with parts (specially any rubber parts) compatible with hydrocarbons (use viton rubber parts instead of EPDM)

- Q: i have a 99 Mitsubishi Eclipse and my Car started to leak water and as soon as i start to put water it starts to leak and it wont take in the water that has on the side as well. what should i do or what do you recommend?

- You did not mention the sub-model of your eclipse (if it is a spyder or not) so there is no way to know the engine option, the2.0L (non-turbo) the 2.0L (turbo) or the 2.4L? But you don't have too many options! If the water runs out of it as soon as you put it in then obviously you cannot drive it or you will do further damage to the vehicle. You need to be able to see where it is coming from (as it shouldn't be too hard by the amount it is leaking. If the water is coming out from behind the timing cover then there is an issue with the pump, but, as the other poster said, it may also be a split hose!

- Q: I REPLACED MY WATER PUMP ON MY 1988 CHEROKEE,THE NEW PUMP STARTED MAKING THE SAME BEARING NOISE.

- I'd wager that whoever installed the new water pump over-tightened the belt. The belt has a tension spec that must be adhered to. Some ham-fisted joke of a mechanic most likely just leaned on the tension pulley with a crowbar and tightened it. Take it to a qualified mechanic and have them measure the belt tension with a gage. Then take that info to the clown that did the work and get your money back -- don't let him ruin another pump; get a qualified mechanic to do the job properly.

- Q: Hi! I need to find out what kind of water pump I need to buy for an 1978 Swinger RV we just bought to refurbish. I've searched the internet, but nothing seems to tell me what kind I need.

- Need to know engine type and size. Without this info, not possible to help you!

Send your message to us

QB Series Peripheral Pumps with Brass Impeller

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords