PVDF Coated Aluminum Coil for Aluminum Composite Panel - Aluminum Coil Home Depot Lowe's

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Grade: 1100/1050/1060 O - H112

Thickness: 0.25mm-4.0mm

Widths: 35mm-1700 mm

Coating: PVDF

Pre-painted Aluminum Coil | |

Grade and Temper | Alloys: 1050, 1100, 3003,3005,3105, 5005,5052,6061,6063,8011,etc Temper: 0-H112 |

Widths | 35mm -1700 mm available |

Thickness | 0.25mm - 4.0mm |

Coating | PE, PVDF or Customize |

Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm – 1270mm |

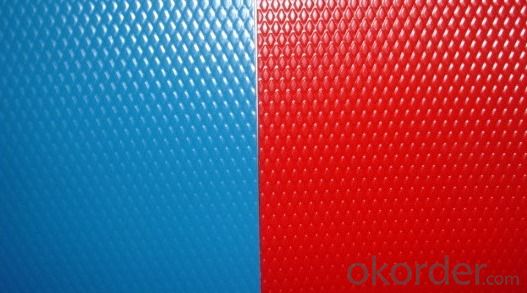

Color | Customized |

Packing Detail | Wooden pallet either eye to wall or eye to sky |

Application | Aluminum Suspended Ceiling ,Aluminum Sandwich Panel, Wall Cladding Panel, Roller Shutter, Metal Roofing, Conner Bead, etc |

Coating Type

FAQ of PVDF Coated Aluminum Coil for Aluminum Composite Panel

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: Just want to know for any boat builders out there. I have been told by my local paddling store that there are no aluminum kayaks. Why couldn't i build one? it cant be weight, I would build the frame from 1/2 inch square aluminum tubing and the body out of 1/32 high grade sheeting. So why does something like this not exist?

- Aluminum kayaks have been built. Few amateur builders know how to weld much less weld aluminum. Ideally you would need female molds and a press. Stretch forming can harden the aluminum and eliminate the need for a frame. If you make male molds, you could force form deck and hull parts and then join them. Read about amateur airplane builders. The big concern with an aluminum kayak is its tendency to stick to river rocks. Every whitewater run has devoured scores of aluminum canoes. Steel is possible.

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- There are great bats that are made out of each, but I generally tend to think that composite bats have better performance. There are aluminum bats that may be better than a given composite, but generally a high-end composite will be better than a high-end aluminum. Composites tend to have larger sweet spots, some span the entire length of the barrel, and the ball will still travel well if hit towards the outside of the sweet spot. contact hitters should look towards composites, because their slower swings will be compensated for with the spring action of the composite material. I think aluminums are better for power hitters because that material has been used for decades and the weight distribution has been better perfected for harder swings.

- Q: Four roller rolling mill roller bearing on the aluminum top how always have holes, in the production process, will be printed on just above the work roll, the work roll used in less than a day, it will produce a pothole, and aluminum plate will be printed from the upper supporting roller above the straight line, the line in the above there are holes.

- Well, typical aluminum plate surface defects in the backup roll print, solution, change support roll.Do not know your factory function division, should have special polishing work roll, support roller grinding workshop, this problem should be addressed to them, sticks are not qualified, how can dry out qualified products?

- Q: Can aluminum coils be used for decorative purposes?

- Yes, aluminum coils can be used for decorative purposes. They are commonly used in various decorative applications such as trim work, wall panels, ceilings, and decorative accents. Aluminum coils offer versatility in terms of color, texture, and finish, allowing for creative and aesthetically pleasing designs.

- Q: Why 5052 turn black after annealing during the production of aluminum alloy?

- The aluminum oxide in the surface has been oxidized by other chemical elements.

- Q: Are aluminum coils suitable for air conditioning systems?

- Air conditioning systems can utilize aluminum coils, which are commonly employed due to their numerous advantages. Firstly, aluminum, being a lightweight material, facilitates ease of handling and transportation during installation. Additionally, this lightweight characteristic reduces the unit's overall weight, rendering it more energy-efficient. Moreover, aluminum coils possess exceptional heat transfer properties, thereby enabling efficient air cooling. They exhibit enhanced thermal conductivity, facilitating rapid and effective heat transfer. Consequently, this leads to improved cooling performance and enhanced energy efficiency, resulting in reduced electricity consumption and long-term cost savings. Furthermore, aluminum coils surpass other materials, such as copper, in terms of superior corrosion resistance. Given the exposure of air conditioning systems to moisture and humidity, this resistance is crucial. Aluminum coils can withstand these conditions without corroding or deteriorating, ensuring a longer lifespan and reliable performance. Another advantage of aluminum coils lies in their affordability. Aluminum is a cost-effective material, making it a favored choice among air conditioning manufacturers. This affordability subsequently translates into lower costs for consumers, making air conditioning systems more accessible and economically viable. In conclusion, the suitability of aluminum coils for air conditioning systems is evident due to their lightweight nature, impressive heat transfer properties, corrosion resistance, and affordability. They offer efficient cooling capabilities, durability, and cost-effectiveness, establishing themselves as the preferred choice for air conditioning units.

- Q: How much cube is the 0.9mm aluminum rolling?

- This is a common problem. Anyone who had received high school education can calculate it very quickily. One way is to calculate sectional area with circular area, then times the thickness of the aluminum rolling. Another way is to use the outer diameter circular area to subtract the core area and then times the thickness of aluminum rolling.

- Q: What are the different color options for anodized aluminum coils?

- Anodized aluminum coils offer a wide range of color options to choose from. The anodization process involves immersing the aluminum in an electrolyte solution and applying an electric current to create a protective oxide layer on the surface. This oxide layer can be dyed in various colors, allowing for customization and aesthetic enhancement. Some common color options for anodized aluminum coils include silver, black, bronze, gold, copper, and champagne. These colors are achieved by using different dye solutions during the anodization process. Additionally, there are also various shades and finishes available within each color category, providing further versatility and choice. The color options for anodized aluminum coils are not limited to solid colors only. It is also possible to create patterns, gradients, or even custom designs by applying masking techniques or utilizing advanced printing technologies. This allows for even more creative freedom and the ability to match specific branding or design requirements. Furthermore, anodized aluminum coils offer excellent color retention and durability. The anodized oxide layer not only provides protection against corrosion and wear but also acts as a base for the dyed color, resulting in long-lasting and vibrant finishes. In summary, the different color options for anodized aluminum coils are extensive and diverse, ranging from traditional metallic finishes to bold and unique shades. This variety allows for endless possibilities in architectural, industrial, and decorative applications, ensuring that there is a suitable color option for every project.

- Q: What are the potential applications of recycled aluminum coils?

- Recycled aluminum coils have a wide range of potential applications due to their numerous beneficial properties. One potential application is in the manufacturing of automotive parts. Aluminum coils can be used to create lightweight body panels, engine components, and structural parts, which can help reduce the overall weight of vehicles, leading to improved fuel efficiency and reduced emissions. Another potential application is in the construction industry. Recycled aluminum coils can be used to make roofing materials, siding, gutters, and window frames. Aluminum is known for its durability, corrosion resistance, and ability to withstand extreme weather conditions, making it an ideal choice for construction purposes. Additionally, recycled aluminum coils can be used in the production of packaging materials. Aluminum is widely used for manufacturing beverage cans, food containers, and foil packaging due to its excellent barrier properties, which help to preserve the freshness and quality of the packaged products. Using recycled aluminum coils for packaging can contribute to reducing the environmental impact associated with the production of new aluminum, as well as reducing waste. Furthermore, recycled aluminum coils can be utilized in the manufacturing of electrical equipment. Aluminum is an excellent conductor of electricity, making it suitable for the production of electrical wires, cables, and other electrical components. Using recycled aluminum coils in the production of electrical equipment can help conserve energy and reduce the need for virgin aluminum extraction and processing. Overall, the potential applications of recycled aluminum coils are vast and diverse, ranging from automotive and construction industries to packaging and electrical equipment. By utilizing recycled aluminum coils, we can achieve both environmental and economic benefits, reducing waste, conserving resources, and promoting sustainability.

- Q: Can aluminum coils be used in the production of solar reflectors?

- Yes, aluminum coils can be used in the production of solar reflectors. Aluminum is a commonly used material in the manufacturing of solar reflectors due to its high reflectivity and durability. The coils can be processed and shaped into the desired form for the reflector, allowing for efficient reflection of sunlight onto the solar panels. Additionally, aluminum is lightweight, making it easier to handle and install in solar reflector systems.

Send your message to us

PVDF Coated Aluminum Coil for Aluminum Composite Panel - Aluminum Coil Home Depot Lowe's

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords