Aluminum Mill Coil PVDF Coated Mill Finished Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished PVDF Coated Aluminium Composite Panel Description

Mill Finished PVDF Coated Aluminium Composite Panel is one semi-finished aluminium material. It can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PVDF Coated Aluminium Composite Panel

Mill Finished PVDF Coated Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished PVDF Coated Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PVDF Coated Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PVDF Coated Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

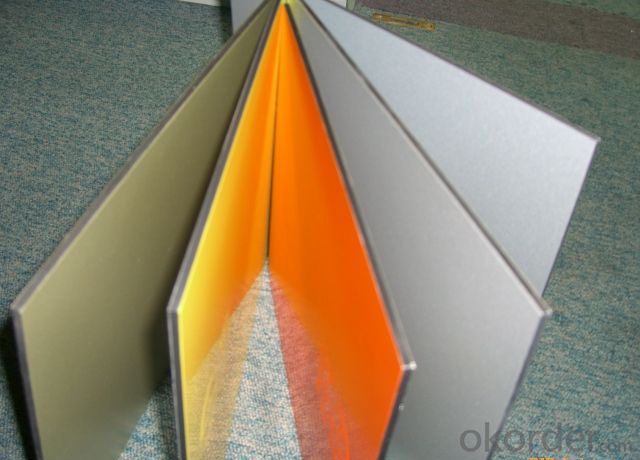

6. Image of Mill Finished PVDF Coated Aluminium Composite Panel

7. Package and shipping of Mill Finished PVDF Coated Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to energy-efficient appliance manufacturing?

- Aluminum coils play a significant role in energy-efficient appliance manufacturing due to their unique properties and benefits. Firstly, aluminum is a lightweight material, which means that using aluminum coils in appliances reduces their overall weight. This, in turn, allows for easier transportation and installation, resulting in reduced energy consumption during transportation and reduced strain on the appliance itself. Furthermore, aluminum has excellent thermal conductivity properties, which are crucial in energy-efficient appliance design. When used in coils, aluminum enables efficient and rapid heat transfer, allowing appliances such as refrigerators, air conditioners, and heat pumps to cool or heat more effectively while consuming less energy. This enhanced thermal efficiency not only reduces energy consumption but also improves the overall performance and lifespan of the appliance. Additionally, aluminum coils are highly corrosion-resistant, making them ideal for appliances that come into contact with moisture or humid environments. By using aluminum coils, manufacturers can ensure that their appliances are durable and long-lasting, avoiding the need for frequent repairs or replacements. This durability reduces energy waste associated with the manufacturing and disposal of appliances. Moreover, aluminum is a highly recyclable material, with the potential for infinite recycling without losing its properties. By incorporating aluminum coils into appliance manufacturing, manufacturers can promote sustainability and reduce their carbon footprint. The use of recycled aluminum also requires significantly less energy compared to producing new aluminum, further contributing to energy efficiency. In conclusion, aluminum coils contribute to energy-efficient appliance manufacturing through their lightweight nature, excellent thermal conductivity, corrosion resistance, recyclability, and overall durability. By utilizing these advantages, manufacturers can create appliances that are not only more energy-efficient but also more sustainable and long-lasting, benefiting both consumers and the environment.

- Q: my text says aluminium does not corrode much as a passive aluminium oxide layer is formed on it.Well other metals such as sodium adn potassium also form oxides. Why dont their oxides prevent further oxidation ?

- sodium oxide and potassium oxide are water soluble aluminium oxide is not water soluble. the layer formed of oxide on the aluminium surface is coherent and adherent with no pores and stuck to the metal surface. the layer is also passive to most acids and alkalies except HCl and anti passive ions if present. sodium oxide and potassium oxide dissolve in any aqueous medium forming the corresponding alkalies NaOH and KOH leaving the fresh metal surface exposed to more corrosion. also the reaction of Na and K with aqueous media like water and acids is quite vigorous and fast unlike aluminium which is mu less reactive

- Q: is there any kind of solder or technique that can solder copper to aluminium? or is it just not possible!?

- Conventional tin/lead alloys cannot be used to solder aluminium to anything: it's just not possible.

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a widely used material in the food industry due to its excellent properties such as its lightweight, durability, corrosion resistance, and heat conductivity. These qualities make aluminum coils suitable for various applications in food storage facilities. Aluminum coils can be utilized in refrigeration systems, air conditioning units, and food storage cabinets, among others. Additionally, aluminum is non-toxic and does not react with food or alter its taste, making it a safe option for food storage. However, it is important to ensure that the aluminum coils used in food storage facilities are properly cleaned and maintained to prevent any potential contamination.

- Q: What are the advantages of using aluminum coils in HVAC systems?

- Using aluminum coils in HVAC systems offers several advantages. Firstly, aluminum coils are significantly lighter than traditional copper coils, which makes them easier to handle and install. This not only reduces labor and transportation costs but also puts less stress on the HVAC system, resulting in less wear and tear over time. Another benefit of aluminum coils is their superior resistance to corrosion. Aluminum naturally resists rust and oxidation, prolonging the lifespan of the coils and enhancing the overall durability of the HVAC system. This resistance to corrosion also helps maintain system efficiency by keeping the coils clean and free from debris buildup. Additionally, aluminum coils have excellent heat transfer properties. They efficiently absorb and release heat, allowing the HVAC system to cool or heat the air more effectively. This improved heat transfer efficiency can lead to energy savings and reduced operating costs, as less energy is required to achieve the desired temperature. Furthermore, aluminum coils are more environmentally friendly than copper coils. Aluminum is highly recyclable, contributing to waste reduction and resource conservation. The manufacturing process for aluminum coils also requires less energy and produces fewer greenhouse gas emissions, making it a sustainable choice for HVAC systems. In conclusion, the benefits of using aluminum coils in HVAC systems include lighter weight, corrosion resistance, superior heat transfer properties, energy efficiency, and environmental sustainability. These advantages make aluminum coils the preferred choice for many HVAC professionals and homeowners.

- Q: Can aluminum coils be used in aerospace heat exchangers?

- Yes, aluminum coils can be used in aerospace heat exchangers. Aluminum is widely used in aerospace applications due to its lightweight and excellent heat transfer properties. It offers good corrosion resistance, high thermal conductivity, and is cost-effective, making it a suitable material for heat exchangers used in aircraft and other aerospace systems.

- Q: So i like eating frozen foods like wings or bagel bites and i cook them in my toaster oven with aluminum foil under them on top of the tray. I heard using aluminum is bad for you and can get you diseases or illnesses. Is this true and should i stop using aluminum foil? i eat these frozen foods maybe 3-4 times a week

- Aluminium has a relatively low melting point so some of the thin metal can be melted enough to release harmful chemicals used to manufacture the foil although the melting is not noticeable. I personally would switch to tin foil but due to the amount of time that aluminium foil has been being produced the effects and dangers of using it are not yet proven

- Q: Some properties of aluminum are summarized in the following list.normal melting point 658°C heat of fusion 3.95 kJ/g normal boiling point 2467°C heat of vaporization 10.52 kJ/g specific heat of the solid 0.902 J/g°C Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point? In KJCalculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C? In KJCalculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C? In KJ

- Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point in KJ- 1.58 mol x 26.98 g/mol x 0.902 J/g°C x (658 - 33)°C x 1 kJ/1000 J = 24.03 kJ Calculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C In KJ- 1.02 mol x 26.98 g/mol x 3.95 kJ/g = 108.7 kJ Calculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C In KJ- 1.02 mol x 26.98 g/mol x 10.52 kJ/g = 289.5 kJ

- Q: What are the different coil packaging options for aluminum coils?

- Customers have several choices when it comes to packaging aluminum coils. One option is the wooden crate, which provides excellent protection during transportation and storage. These crates are made of sturdy wood and are designed to securely hold the coils in place, preventing any damage. Metal bands or straps are often used to further secure the coils. Another popular choice is the steel cage, which is durable and offers exceptional protection. These cages are made of heavy-duty steel and can withstand the demands of transportation. Like wooden crates, steel cages are equipped with straps or bands to prevent movement and damage. Stretch wrap and shrink wrap are also used for packaging aluminum coils. Stretch wrap is a plastic film that tightly wraps around the coils, creating a protective layer. Shrink wrap, on the other hand, is a plastic film that is heated and shrinks tightly around the coils. Both options provide protection against dust, moisture, and other environmental factors. Some companies may choose customized packaging solutions, such as custom-made crates or containers, to meet their specific needs. These solutions can be tailored to accommodate the size, weight, and other unique requirements of the coils, ensuring maximum protection. Overall, customers can choose from wooden crates, steel cages, stretch wrap, shrink wrap, or customized packaging solutions for their aluminum coil packaging needs. Each option offers different levels of protection, allowing customers to choose what suits their requirements and budget.

- Q: Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in heat exchangers within wastewater treatment plants to transfer heat effectively and efficiently. They are resistant to corrosion and can withstand the harsh environment of wastewater treatment processes.

Send your message to us

Aluminum Mill Coil PVDF Coated Mill Finished Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords